Prestress automatic unloading equipment for beam yard

An automatic blanking and prestressing technology, which is applied in the direction of packaging and bundling materials, can solve the problems of easy injury, inaccurate blanking accuracy, and inconvenient cutting, etc., and achieve the goal of improving practicability, firmness, and reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

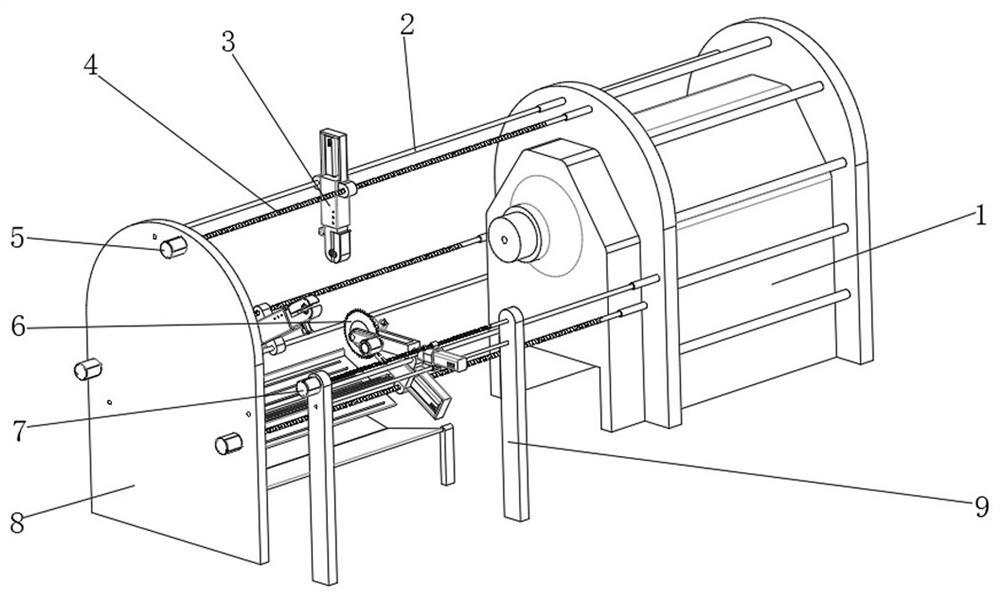

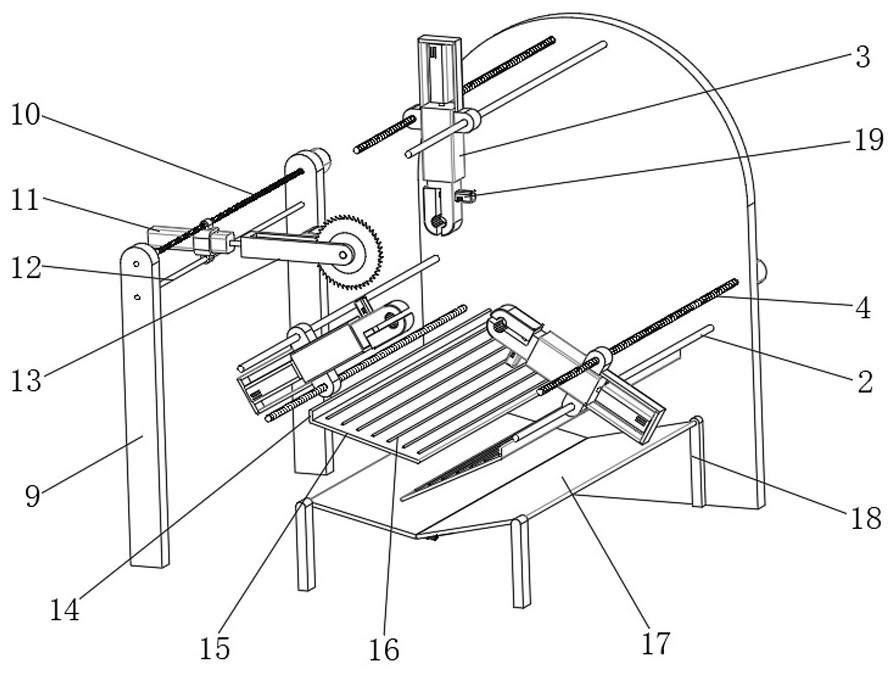

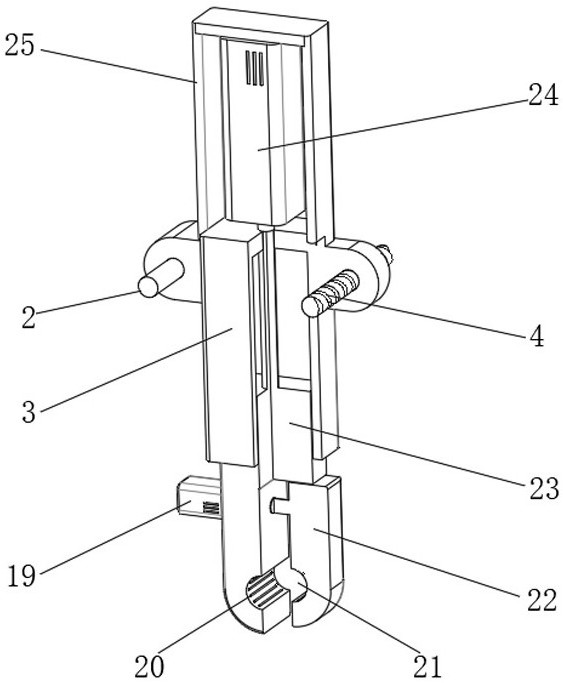

[0036] A kind of prestressed automatic unloading equipment for beam field, such as Figure 1-5 As shown, it includes an equipment main body 1, a cutting mechanism and three clamping mechanisms. One side of the equipment main body 1 is provided with a mounting frame 8, and a first guide rod 2 is fixed between the mounting frame 8 and the equipment main body 1 by screws. The mounting frame 8 One side of the outer wall is fixed with a first translation motor 5 by screws, and the output end of the first translation motor 5 is connected with a first translation screw 4 in rotation. The clamping mechanism includes a first adjustment frame 3, a first clamping part 23 and a second clamp The holding part 22, the first adjusting frame 3 is slidably connected to the outer wall of the first guide rod 2, and the first adjusting frame 3 is connected to the outer wall of the first translation screw 4 through threads, and the top outer wall of the first adjusting frame 3 is fixed with a fixed ...

Embodiment 2

[0046] A kind of prestressed automatic unloading equipment for beam field, such as figure 1 As shown, in order to improve the stability during cutting; this embodiment makes the following improvements on the basis of Embodiment 1: the outer walls of the second clamping part 22 and the first clamping part 23 are provided with a cutting opening 31, and the cutting opening The position of 31 is adapted to the position of cutting wheel 6; by setting structures such as cutting opening 31, when cutting, cutting knife wheel 6 can be sent into cutting opening 31 for cutting, which ensures that the first clamping part 23 of the cutting process The stability of clamping the steel strand by the second clamping portion 22 improves the cutting effect. In the technical solution of the present invention, it is necessary to cooperate with the tying machine to bundle the steel bars. The tying machine is all models or types in the art that can be applied to the prestressed automatic unloading e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com