Universal press-fitting platform press-fitting mechanism

A press-fitting device and press-fitting technology, which is applied in the field of press-fitting mechanism of general-purpose press-fitting platform, can solve the problems of low degree of automation, slow press-fitting speed, time-prone fatigue, etc., achieve high degree of automation, fast press-fitting speed, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

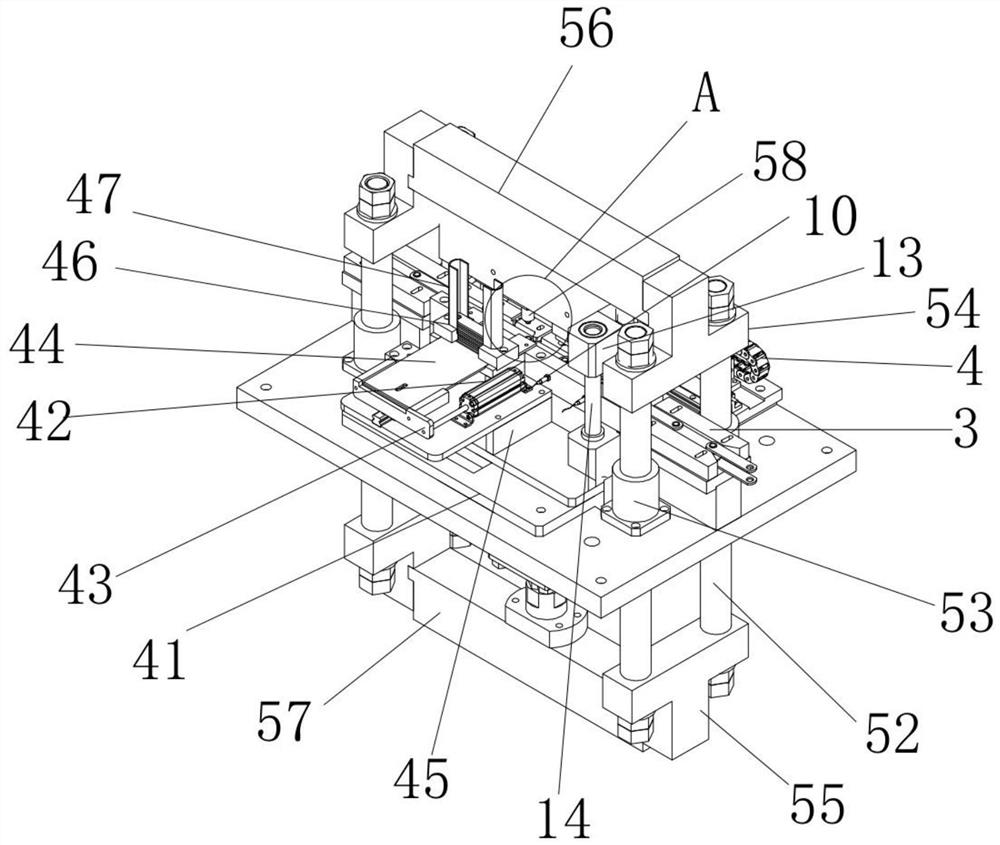

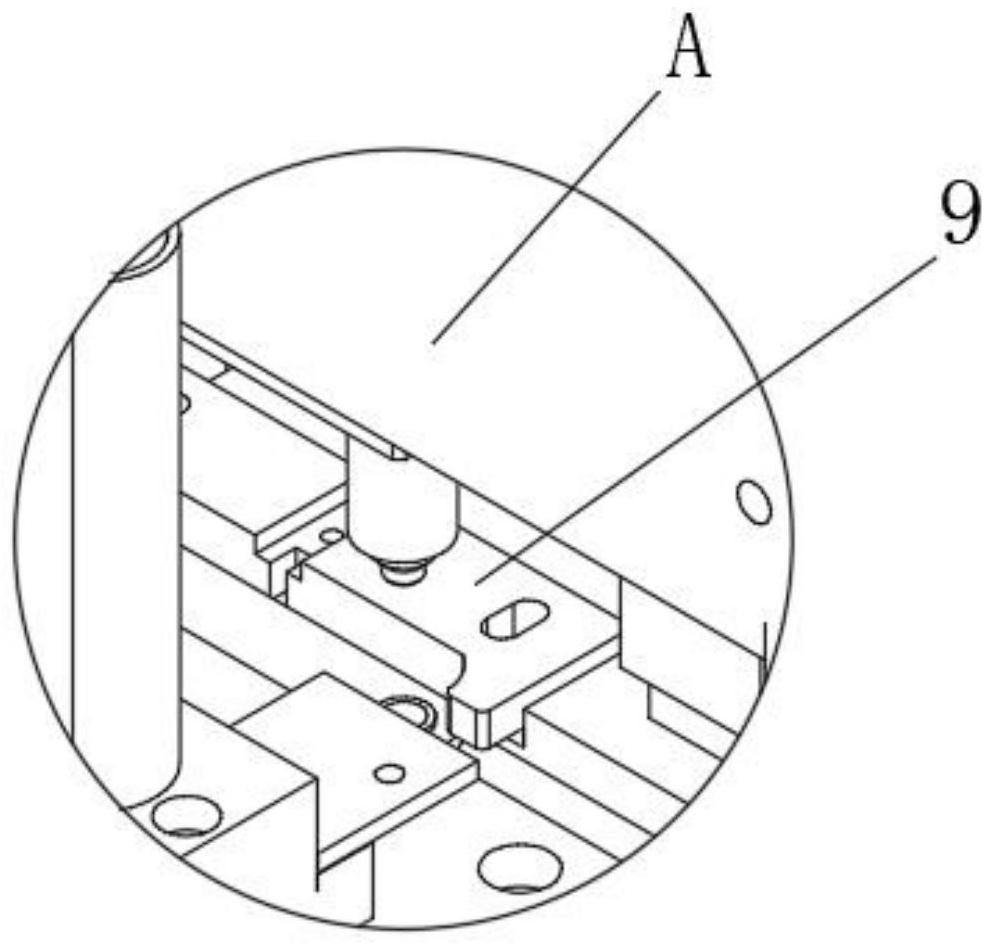

[0022] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

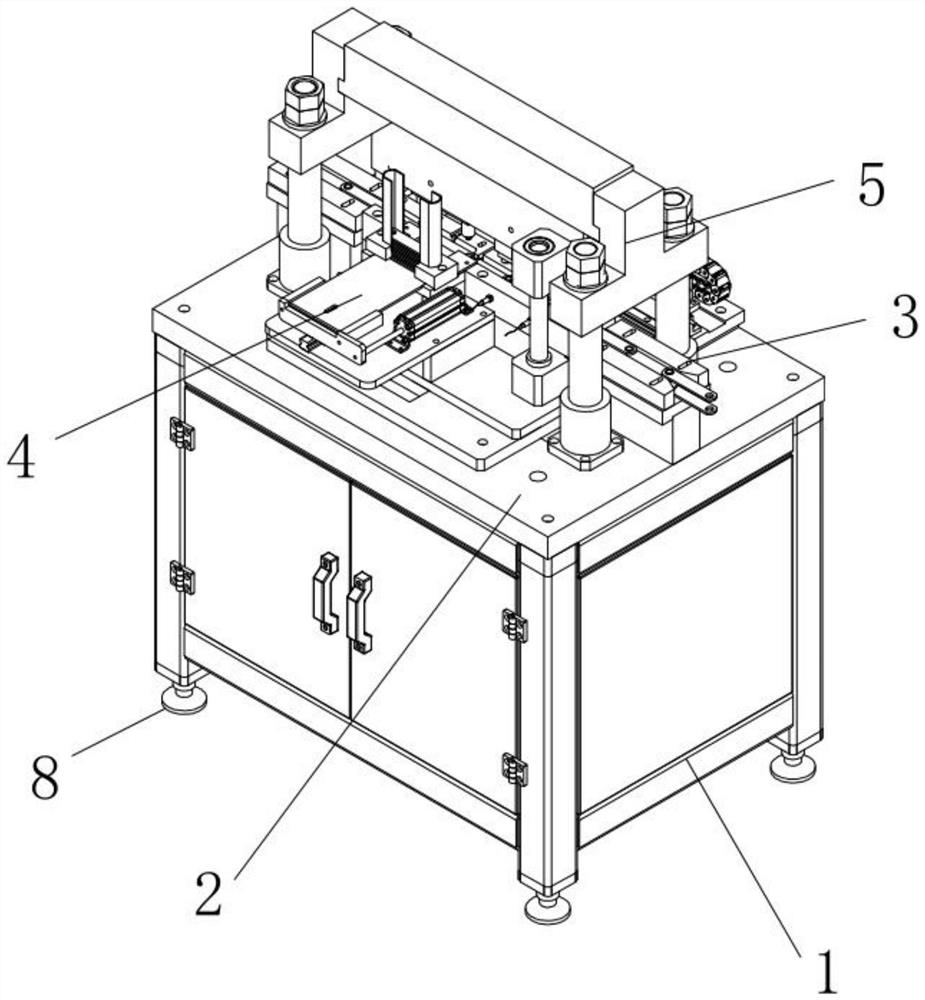

[0023] like Figure 1-5 Described a kind of universal press-fitting platform press-fit mechanism, comprises frame 1, feeding guide rail 3, feeding device 4 and press-fitting device 5, described frame 1 is provided with workbench 2, and feed guide rail is installed on workbench 2 3. Use the feeding device 4 to push the pin piece into the upper part of the feeding guide rail 3, and perform positioning, and press the pin piece into the chain through the pressing device 5.

[0024] The feeding device 4 includes a transition plate 41, a first cylinder 42, a first cylinder connecting plate 43, a cylinder feeding plate 44, a first cylinder mount 45 and a blanking assembly, and the transition plate 41 is equipped with a first cylinder mount 45 , the first cylinder mount 45 is provided with a moving guide rail, the first cylinder 42 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com