A wear repair device for the meshing surface of the tooth tip of the open gear of the hydraulic pliers

A technology for wear repair and gear teeth, which is applied to fixed grinding wheel devices, grinding/polishing safety devices, grinding machines, etc., can solve the problems of grinding fluid splashing, dirty equipment, waste, etc., to avoid grinding fluid Effects of leakage, equipment weight reduction, and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

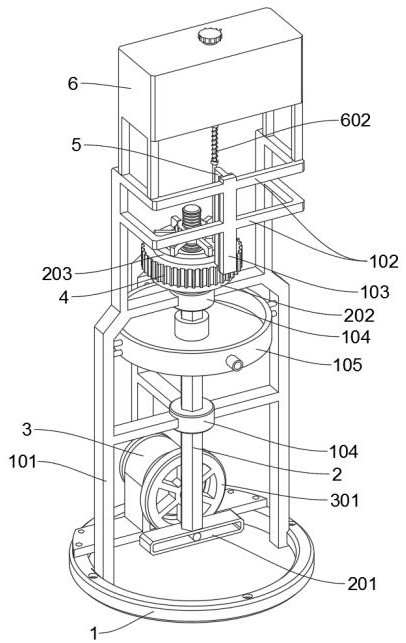

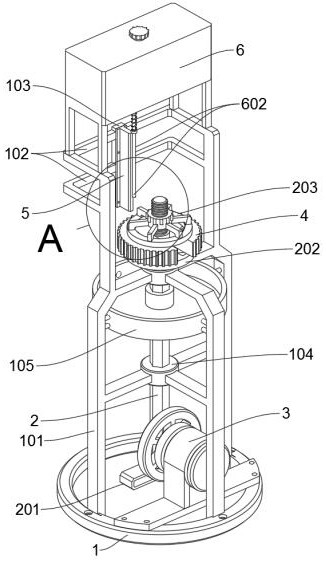

[0026] see Figure 1 to Figure 7 , Embodiment 1 provided by the present invention: a wear repair device for the tooth tip meshing surface of an open gear of a hydraulic pliers, including a base 1; There is a three-claw support frame 101 welded and fixed on the top. The top of the three-claw support frame 101 and the middle position of the internal space are welded with two positioning rings 104 at intervals up and down, and there is a vertical sliding position on the two positioning rings 104. A rectangular grinding fluid tank 6 is welded above the top of the hexagonal slide shaft 2 and the three-claw support frame 101; the distance between the sand bar 5 and the opening gear 4 in the initial state of sliding down is kept, and the sand bar 5 is made of diamond and resin mixture. and the tooth surface of the cotter gear 4 is in frictional contact with the sand strip 5; the space between the sand strip 5 and the cotter gear 4 can facilitate the sliding and disassembly of the cot...

Embodiment 2

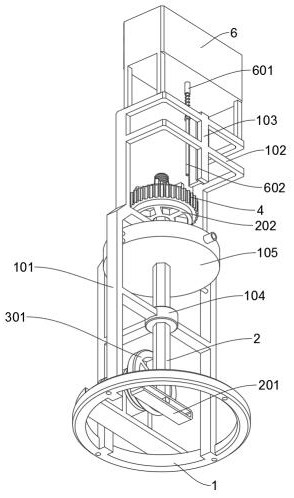

[0029] see Figure 8 to Figure 9 , Embodiment 2 provided by the present invention: a wear repair device for the tooth tip meshing surface of an open gear of a hydraulic pliers, including a grinding fluid tank 6, the grinding fluid tank 6 includes a sleeve 601, and the middle of the bottom of the grinding fluid tank 6 There is a casing 601 connected by position welding; a liquid outlet pipe 602, and the inside of the casing 601 is pushed through and slid through a spring to install a liquid outlet pipe 602, which is used to discharge the grinding fluid, and the liquid outlet pipe 602 is The spring can automatically bounce back and push down the liquid outlet pipe 602 to reset after the opening gear 4 slides and separates from the liquid outlet pipe 602.

Embodiment 3

[0030] see Figure 10 , Embodiment 3 provided by the present invention: a wear repair device for the tooth tip meshing surface of an open gear of a hydraulic pliers, which also includes a grinding fluid tank 6, and the grinding fluid tank 6 also includes a circular baffle plate 603, a liquid outlet pipe 602 A circular baffle 603 is welded and fixed at the top of the top of the casing. This circular baffle 603 slides down against the top opening of the casing 601. Through the circular baffle 603, the liquid outlet pipe 602 can slide the casing 601 back when it slides back. Resist sealing and avoid grinding fluid leakage, which provides convenience for the normal implementation of the intermittent liquid supply function of the liquid outlet pipe 602 .

[0031] Working principle: First, fit the notch on the open gear 4 with the positioning column on the top of the hexagonal sliding shaft 2 and press against the top of the support ring 202, press and fix the open gear 4 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com