Precast concrete component production line

A technology for prefabricated components and production lines, applied in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve problems such as large space occupation, and achieve the effect of solving large space occupation, rapid expansion, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

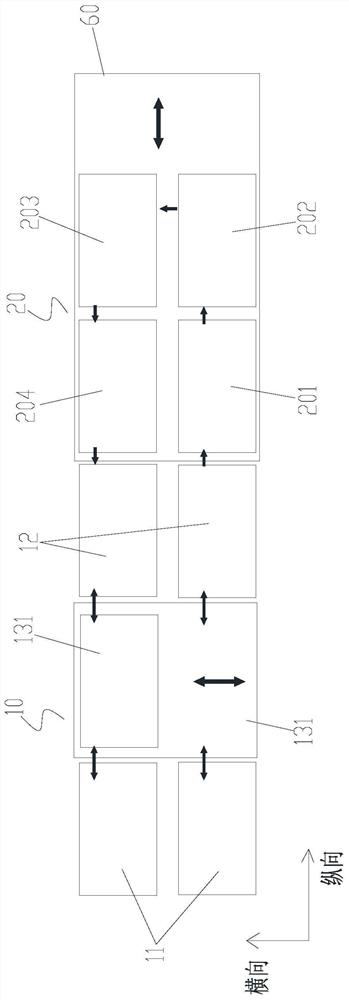

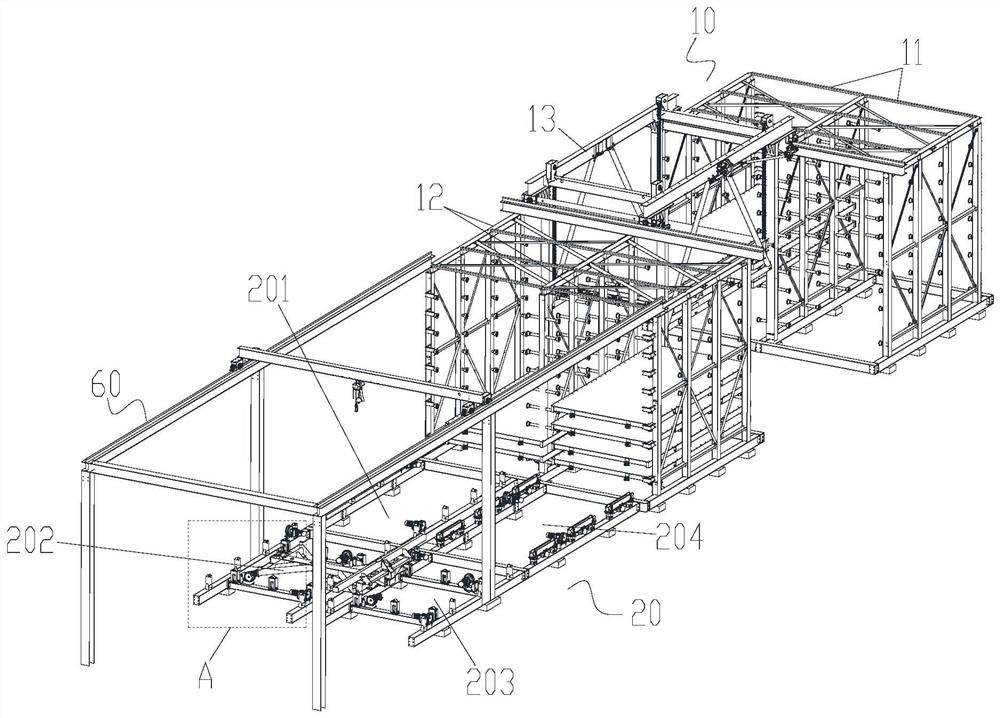

[0041] For the convenience of description, "horizontal" and "vertical" in the following are figure 1 in the direction indicated. Specifically, the longitudinal direction refers to the length direction of the mold table when the production line circulates, and correspondingly, the transverse direction refers to the width direction of the mold table when the production line circulates. Of course, "horizontal" and "longitudinal" represent two perpendicular directions, and those skilled in the art can determine the specific directions represented by "transverse" and "longitudinal" according to the actual situation of the production line.

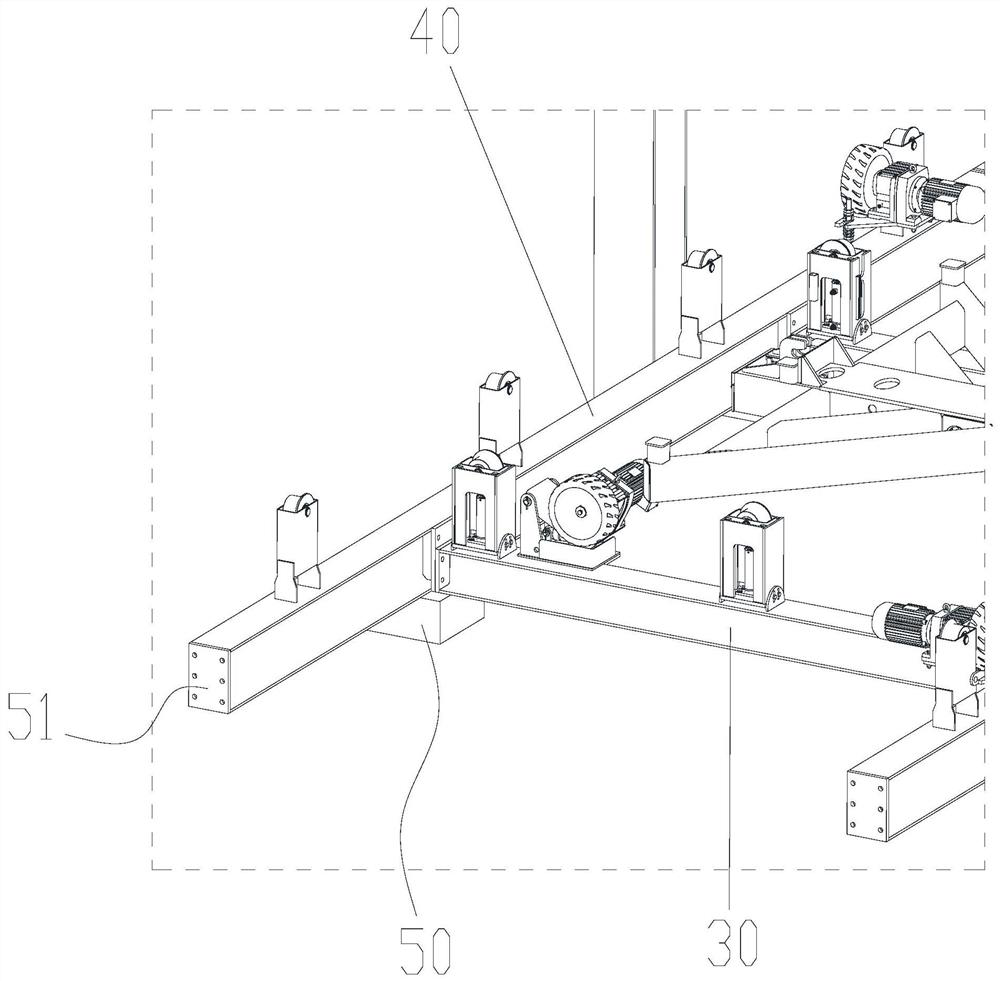

[0042] Such as Figure 1 to Figure 3 As shown, the concrete prefabricated component production line in this embodiment includes a curing station 10 , a circulation production line 20 , a transverse driving module 30 and a longitudinal driving module 40 . Wherein, the circulation production line 20 is arranged at the side of the maintenance sta...

Embodiment 2

[0070] Such as Figure 6 As shown, the difference between the concrete prefabricated component production line of the second embodiment and the first embodiment above is that two troweling stations 205 are extended in the circulation production line 20 . Specifically, the two polishing stations 205 are arranged on a side of the maintenance station 10 away from the first station 201 , the second station 202 , the third station 203 and the fourth station 204 .

[0071] From Figure 6 It can be seen that, compared with the first station 201 , the second station 202 , the third station 203 and the fourth station 204 , the two polishing stations 205 are respectively located on both sides of the maintenance station 10 . Wherein, one polishing station 205 is arranged at the opening of one curing kiln in the first curing kiln 11 ; the other polishing station 205 is arranged at the opening of another curing kiln in the first curing kiln 11 . The two polishing stations 205 are connect...

Embodiment 3

[0074] Such as Figure 7 As shown, the difference between the concrete prefabricated component production line of the third embodiment and the first embodiment above is that the specific stations of the first station 201, the second station 202, the third station 203 and the fourth station 204 The types are different, and four extension stations are added outside the first station 201 , the second station 202 , the third station 203 and the fourth station 204 .

[0075] Specifically, in the third embodiment, the first station 201, the second station 202, the third station 203, and the fourth station 204 are respectively the first side stripping mold station, the mold table rollover and cleaning workers. position, support side formwork and reinforcement layout station and leveling station. The circulation production line 20 also includes a cloth vibrating station 206, a cloth station 207, a second stripping mold station 208 and a third stripping mold station 209, wherein the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com