Oil press easy to clean

A technology for oil presses and barrels, applied to presses, manufacturing tools, etc., can solve the problems of blocked oil outlets, difficult to clean oil outlets, and difficult to clean oil outlets, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

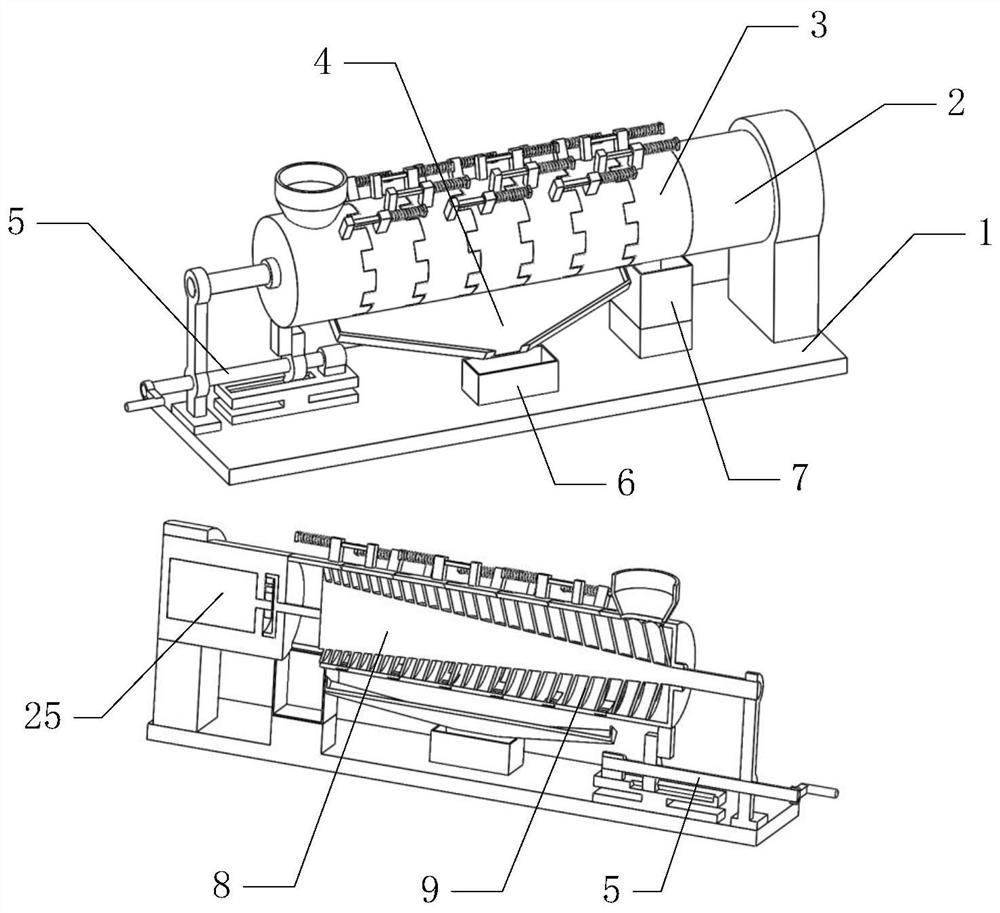

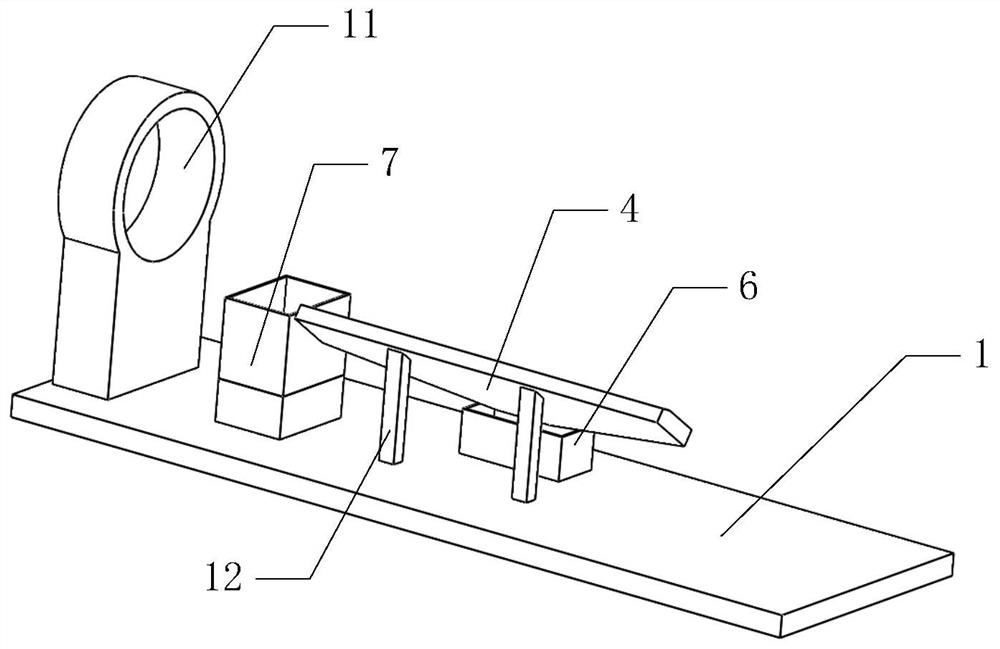

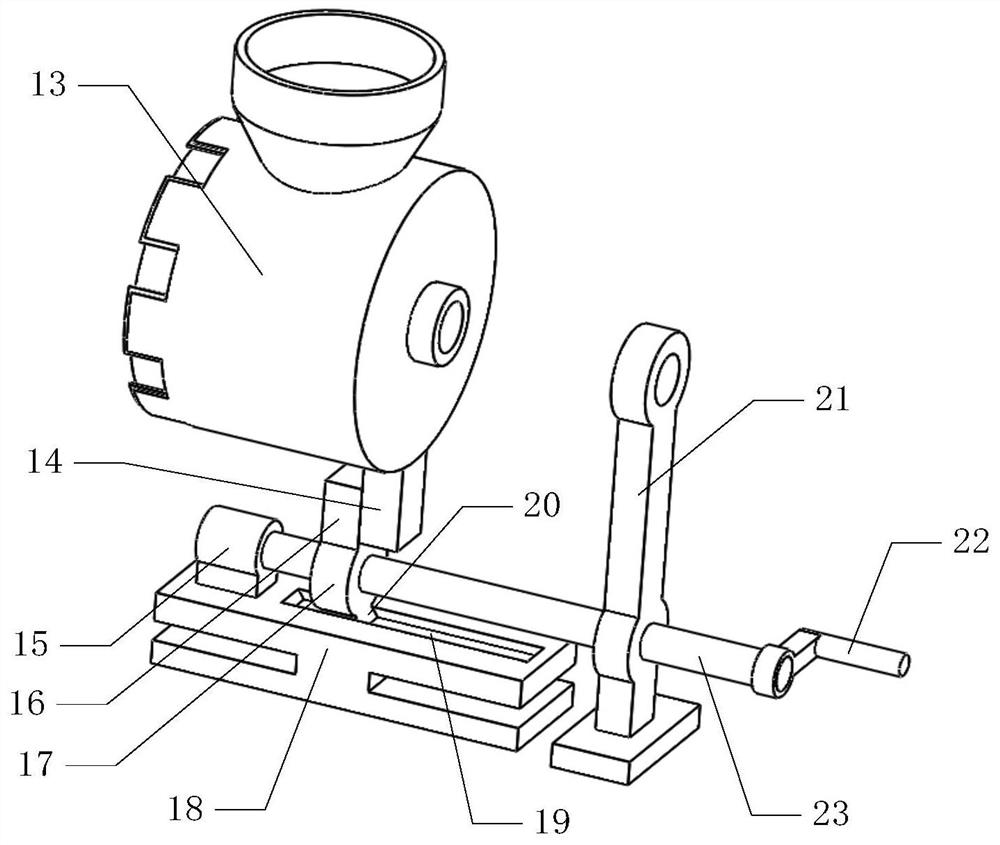

[0035] Such as figure 1 As shown, it includes a base 1, a power module 2, a press cylinder 3, an oil pan 4, an adjustment mechanism 5, an oil tank 6, a slag box 7, an installation shaft 8, and a press screw 9, wherein the power module 2 passes through the first support 11 Fixedly installed on the upper side of the base 1, the power module 2 is composed of a housing 24, a motor 25, a planetary gear 26, an output shaft 27, a planetary shaft 28, a ring gear 29 and a sun gear 30, and the housing 24 passes through the first support 11 fixed on the upper side of the base 1, such as Figure 4 As shown, the motor 25 is fixedly mounted on the inner side of the housing 24, the sun g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap