Method and device for determining state of electropneumatic turnout switch machine

A determination method and technology of switch machines, applied in transportation and packaging, hydraulic equipment for manipulating turnouts or line breakers, railway car body parts, etc., can solve the state detection efficiency of empty turnout switch machine and the accuracy of fault location Low-level problems, to achieve the effect of improving the efficiency of status detection and the accuracy of fault location, improving driving safety, and shortening the duration of status detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

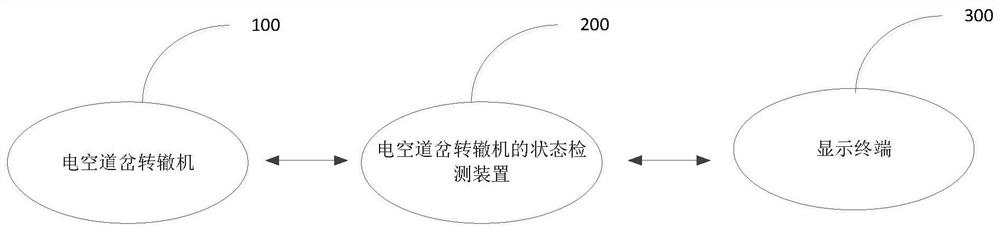

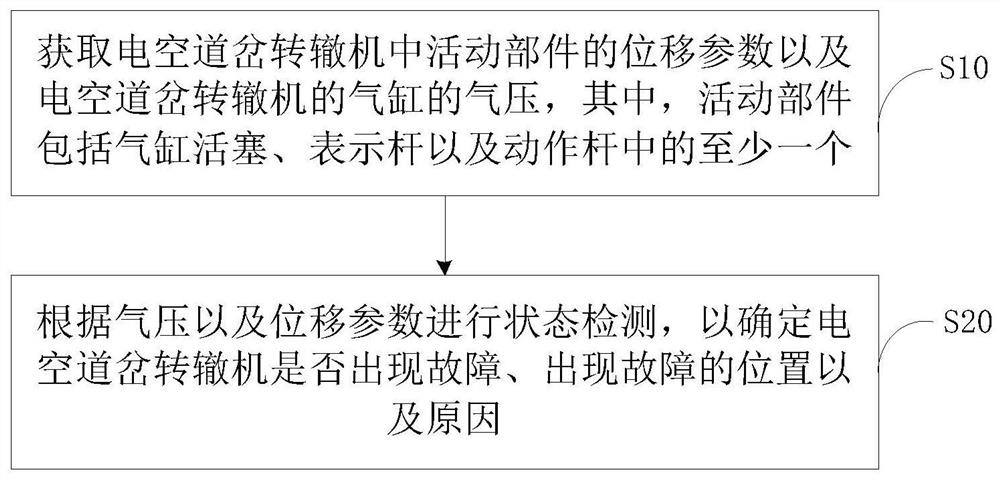

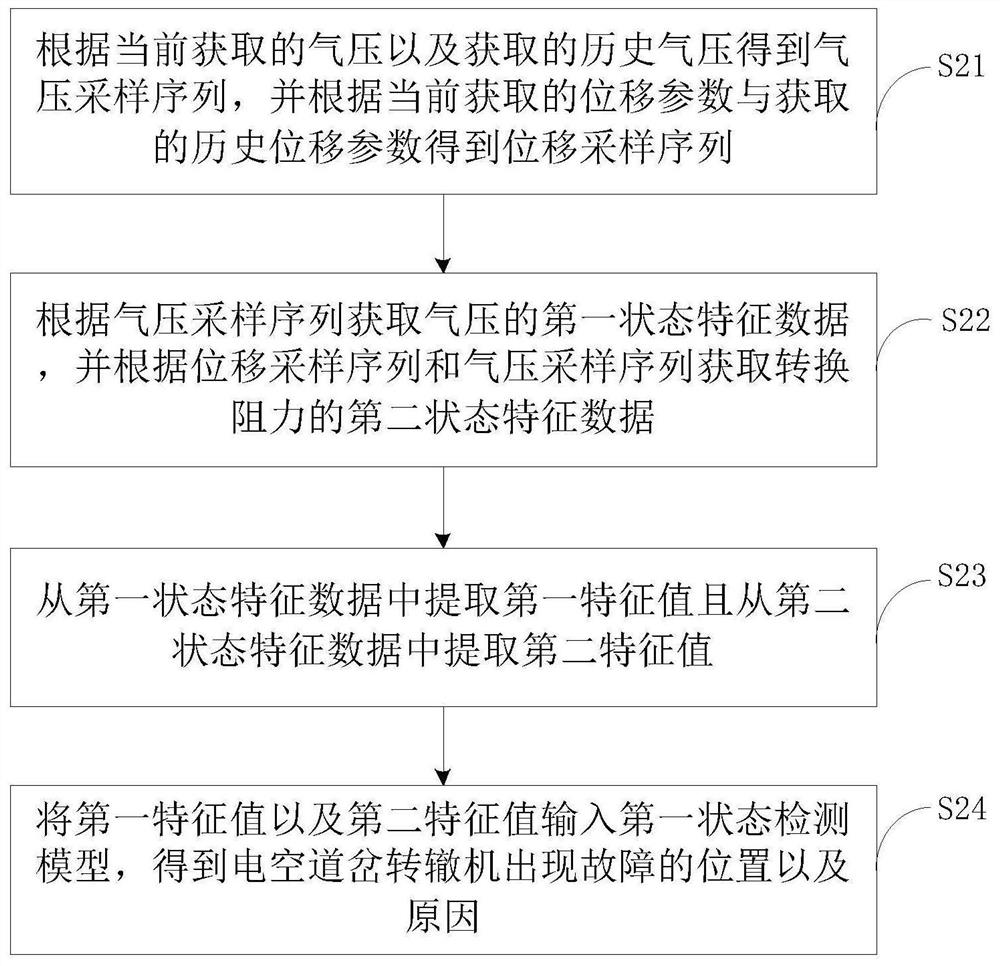

[0071] refer to figure 2 , figure 2 It is the first embodiment of the method for determining the state of the electro-pneumatic switch machine of the present invention, and the method for determining the state of the electro-pneumatic switch machine includes the following steps:

[0072] Step S10, obtaining the displacement parameters of the movable parts in the electropneumatic point switch machine and the air pressure of the cylinder of the electropneumatic point point machine, wherein the movable part includes at least one of a cylinder piston, a display rod and an action rod.

[0073] In this embodiment, the execution subject is a state detection device of an electropneumatic switch machine. For the convenience of description, the device is used below to refer to the state detection device of the electropneumatic switch machine.

[0074] The cylinder in the electro-pneumatic switch point machine is provided with a pressure sensor, which can collect the air pressure in ...

no. 4 example

[0125] refer to Figure 5 , Figure 5 It is the fourth embodiment of the method for determining the state of the electro-pneumatic switch machine of the present invention, based on the third embodiment, step S26 includes:

[0126] Step S261, determine the physical position of the switch and the gap of the switch according to the starting current and the displacement parameters.

[0127] In this embodiment, the current sensor performs sampling according to a preset interval, and the device obtains a starting current sampling sequence based on the currently collected starting current and each historical starting current.

[0128] The starting current is used to control the opening or closing of the positioning electromagnetic pilot valve (reverse electromagnetic pilot valve) of the electropneumatic switch machine. When the control command includes the opening signal of the positioning electromagnetic pilot valve (reverse electromagnetic pilot valve), the positioning electromagn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com