High-blue-phase high-heat-resistance polypropylene composition as well as preparation method and application thereof

A polypropylene composition and high heat resistance technology, applied in the field of polymer materials and their molding and processing, can solve the problem of not being able to ensure heat resistance at the same time, and achieve the effects of cost advantages, easy implementation, and high design freedom

Active Publication Date: 2021-11-02

KINGFA SCI & TECH CO LTD

View PDF12 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005]

In order to overcome the problem in the prior art that it is necessary to rely on phthalocyanine blue pigments to prepare high-blue-phase polypropylene materials and cannot guarantee heat resistance at the same time, the present invention provides a high-blue-phase high-heat-resistant polypropylene composition

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~13

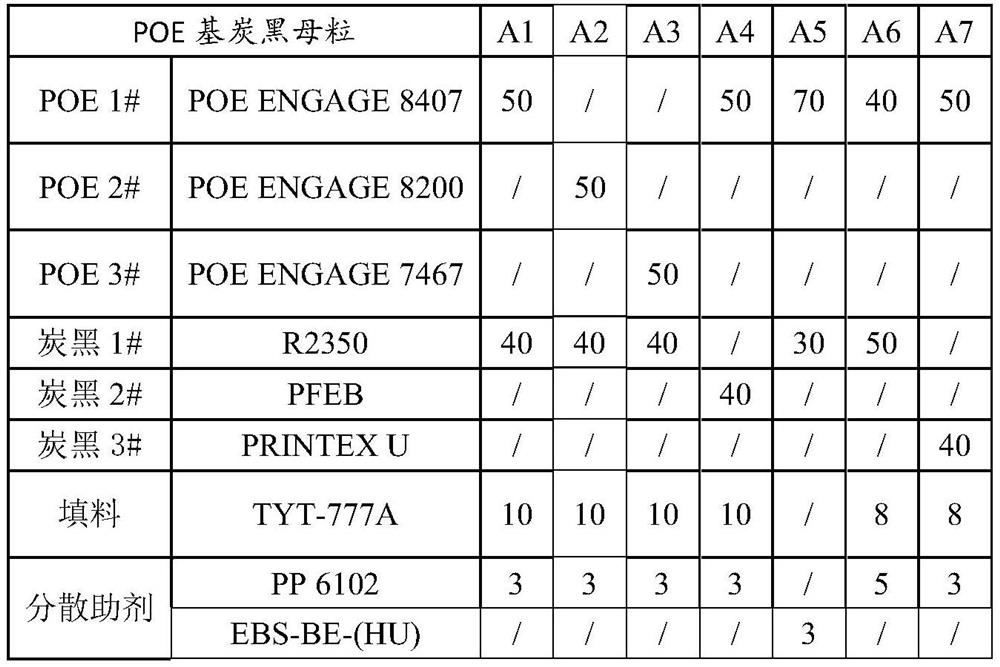

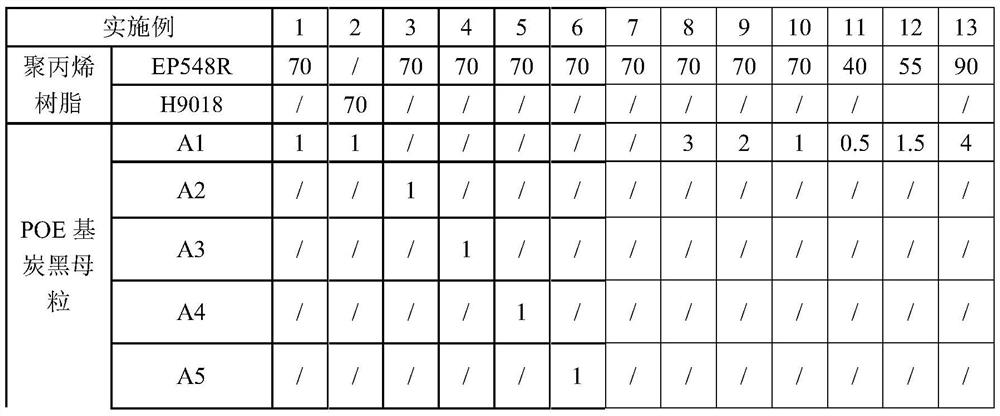

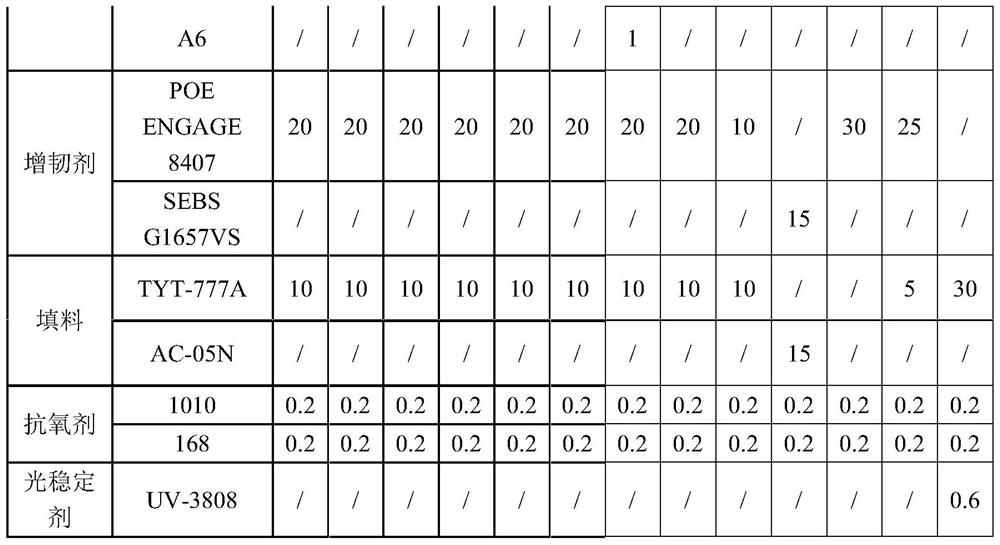

[0094] This embodiment provides a series of polypropylene compositions, wherein, the formula of POE-based carbon black masterbatch is shown in Table 1, and the formula of polypropylene composition is shown in Table 2.

[0095] Table 1 Formula of POE-based carbon black masterbatch (parts)

[0096]

[0097] The formula (part) of table 2 embodiment 1~13

[0098]

[0099]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a high-blue-phase high-heat-resistance polypropylene composition as well as a preparation method and application thereof. The polypropylene composition comprises the following components in parts by weight: 40-90 parts of polypropylene resin, 0-30 parts of a toughening agent, 0-30 parts of a filler, 0.5-4 parts of POE (Polyolefin Elastomer)-based carbon black master batch and 0.2-0.6 part of an antioxidant, wherein the POE-based carbon black master batch is prepared from the following components in parts by weight: 40 to 70 parts of POE resin, 30 to 50 parts of carbon black, 0 to 10 parts of filler and 1 to 5 parts of dispersing aid. According to the invention, the carbon black is firstly dispersed in the POE resin to prepare the POE-based carbon black master batch, and then the polypropylene material is modified, so that the finally prepared polypropylene composition has high blue phase and high heat resistance, and can be well used for preparing automobile interior and exterior ornaments.

Description

technical field [0001] The invention relates to the field of polymer materials and their molding processing, in particular to a high-blue-phase high-heat-resistant polypropylene composition and its preparation method and application. Background technique [0002] As a cost-effective general-purpose plastic, polypropylene is widely used in home appliances and automobiles because it has excellent mechanical properties such as high strength and high toughness, chemical resistance and high heat resistance after modification. For automotive interior polypropylene materials, there are usually high blackness and high blue phase appearance requirements. The blue-phase polypropylene can enhance the visual effect of black; at the same time, because the car is often parked in the open air, the interior of the car is frequently in a high-temperature environment, so the market proposes that the car interior should not be heat-resistant for 400-700 hours at 150 °C. And other thermal oxyg...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/12C08L23/08C08L23/14C08K3/04

CPCC08L23/12C08L23/14C08L2201/08C08K2201/006C08L23/0815C08K3/04

Inventor 卢朝亮陈平绪叶南飚杨波苏娟霞吴亦建左立增陈延安吴国峰罗忠富

Owner KINGFA SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com