Automatic lubricating oil adding system for machine tool bearing and lubricating oil adding method thereof

A technology for adding lubricating oil and lubricating oil, which is applied in the direction of lubricating oil input, engine lubrication, shaft and bearing, etc. It can solve the effect of lubricating oil on lubrication and cooling, enter into the oil storage box, reduce the economic benefits of use, etc. problems, to achieve the effect of improving convenience, avoiding impact, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below. The embodiments of the present invention and all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

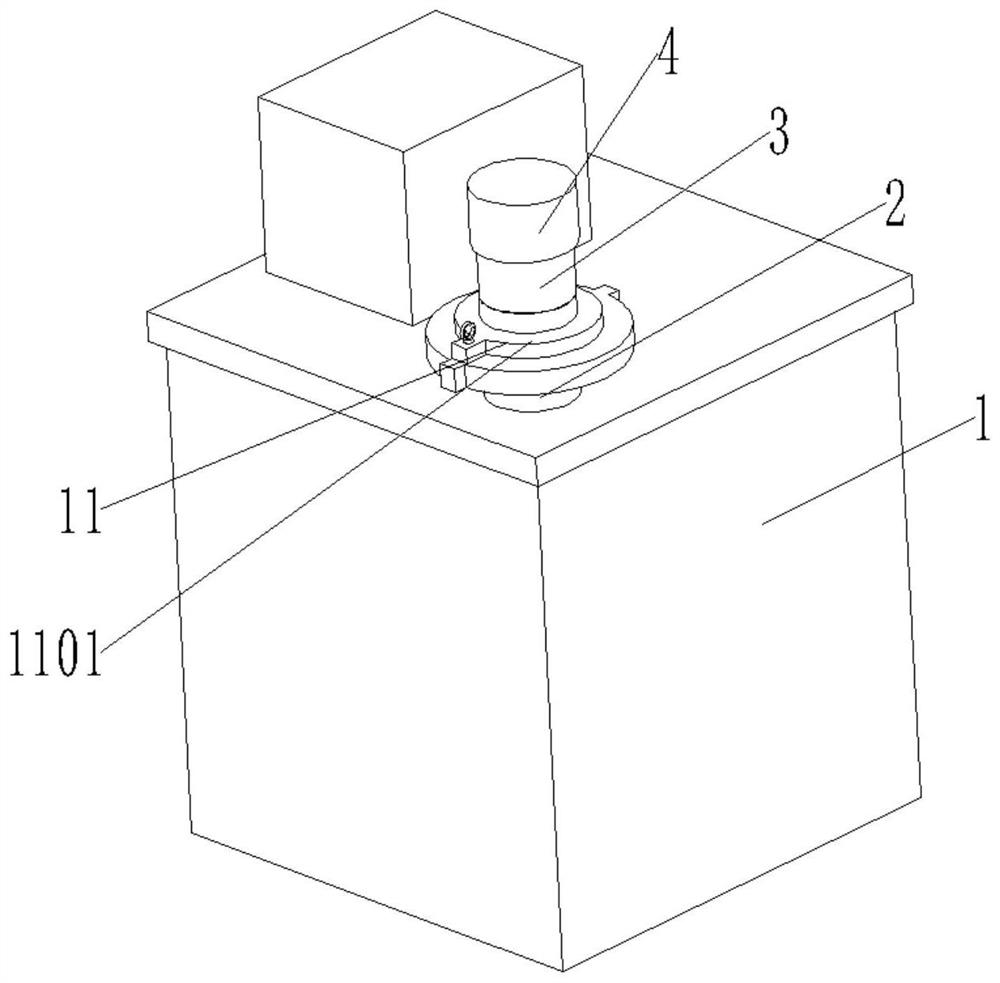

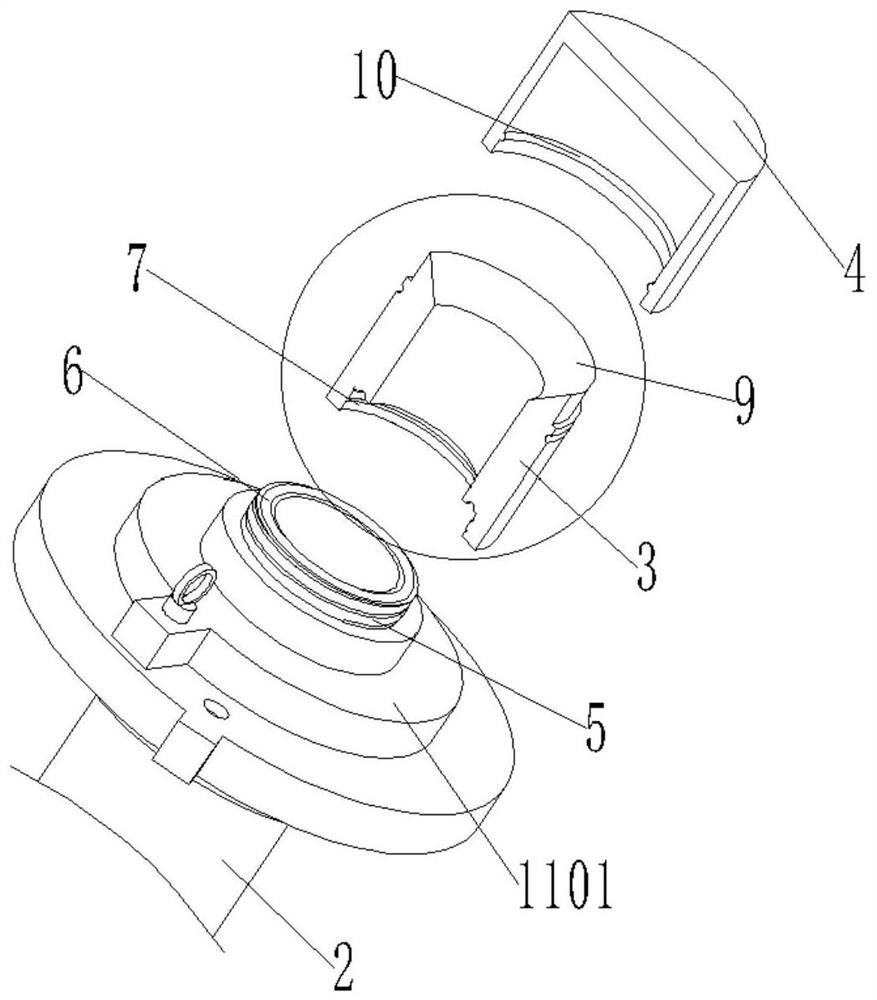

[0026] see figure see Figure 1 to Figure 6 , the present invention provides a technical solution: an automatic lubricating oil system for machine tool bearings. The present invention includes an oil storage box main body 1, an input pipe 2, a connecting pipe 3, a sealing cap 4 and an auxiliary mechanism 11;

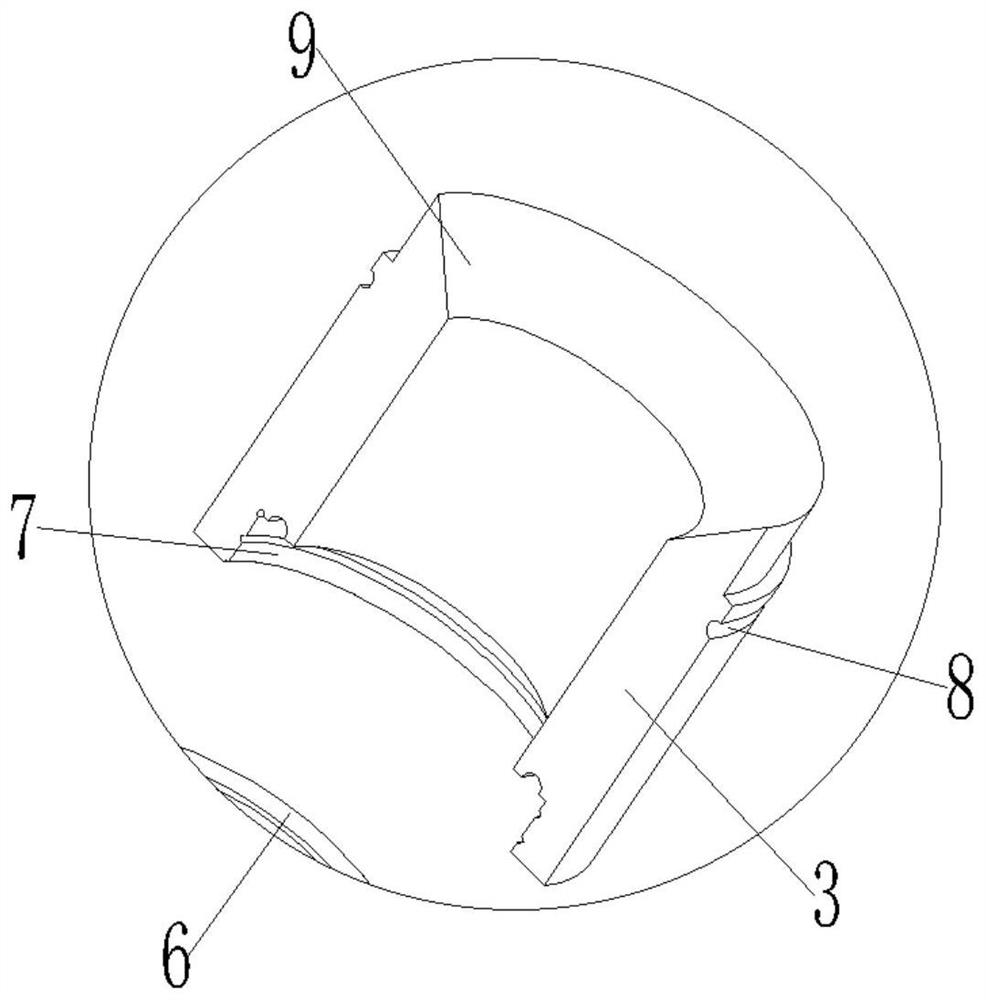

[0027] The main body 1 of the oil storage box is provided with an input pipe 2, one end of the input pipe 2 extends into the inner cavity of the main body 1 of the oil storage box, and the other end is connected with a connecting pipe 3, and the other end of the connecting pipe 3 is connected with a sealing The cap 4, here, a connecting ring 5 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap