Combined heat and power generation system based on multi-heat-source coupling and adjusting method

A technology for cogeneration and cogeneration units, which is applied to steam generation methods using heat carriers, heating systems, and hot water central heating systems, etc., and can solve the problem of increased investment costs, inability to meet, and low peak shaving capacity of thermoelectric units. and other problems, to achieve the effect of reducing investment in pipeline network construction, improving power peak regulation capacity, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0049] Example.

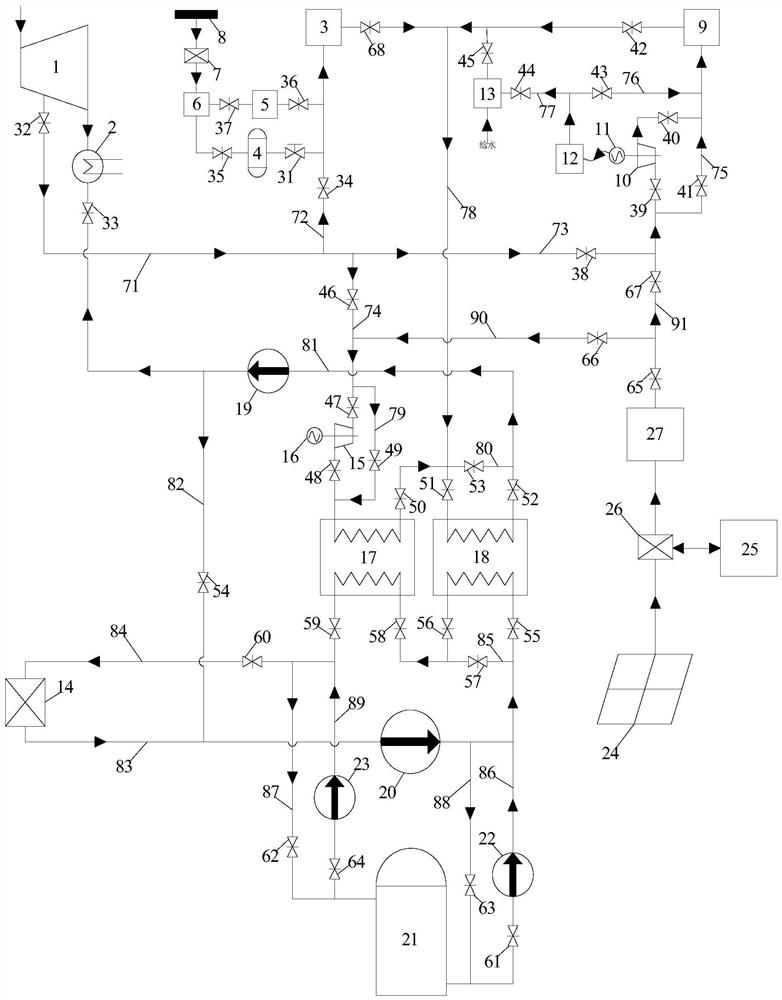

[0050] see figure 1 , in this embodiment, a cogeneration system based on multi-heat source coupling includes: a cogeneration unit 1, a condenser 2, a first-class industrial steam user 3, a steam buffer device 4, a steam decompression device 5, The first steam-type electrode boiler 6, the power control switch 7, the power grid 8, the second type of industrial steam user 9, the first back pressure machine 10, the first generator 11, the second steam-type electrode boiler 12, the steam-water mixing heating device 13 , heating user 14, second back pressure machine 15, second generator 16, steam-water heat exchanger 17, water-water heat exchanger 18, hydrophobic circulation pump 19, heating network wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com