High-combustion-efficiency biomass combustion boiler with energy recovery link

A technology of energy recovery and combustion efficiency, applied in steam boilers, steam generation, steam engine devices, etc., can solve problems such as insufficient fuel combustion, difficult air delivery by the air supply mechanism, and insufficient air, so as to promote full combustion, facilitate falling, The effect of adding air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

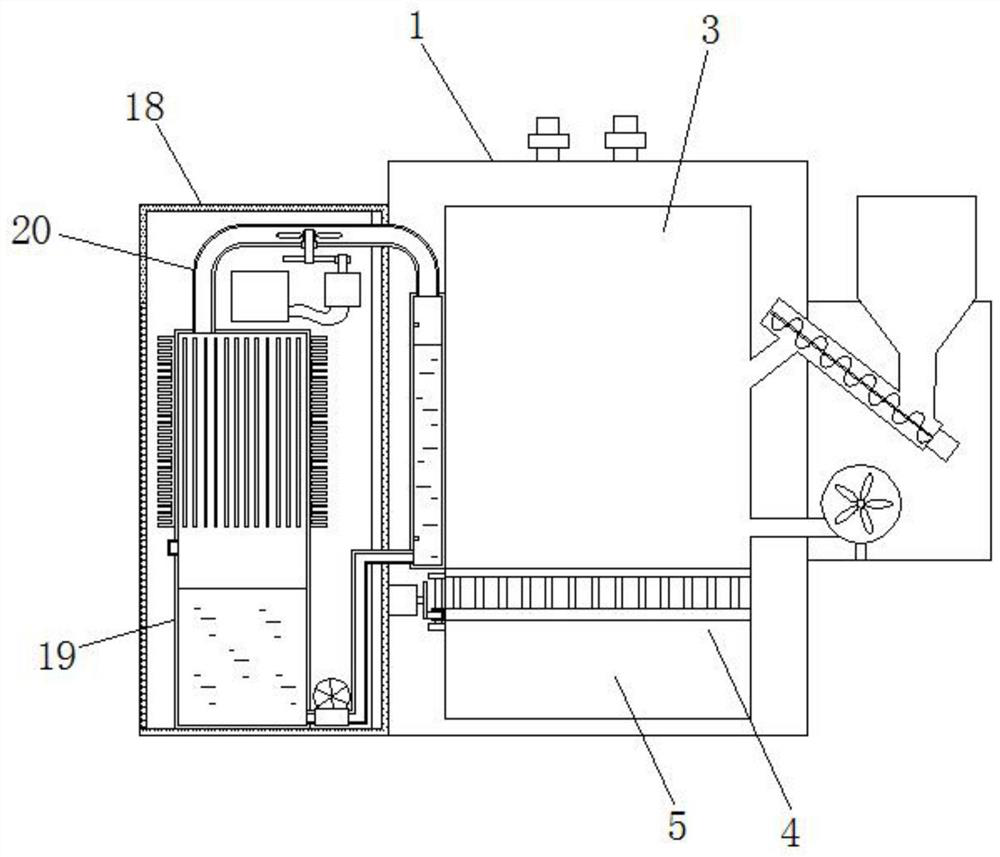

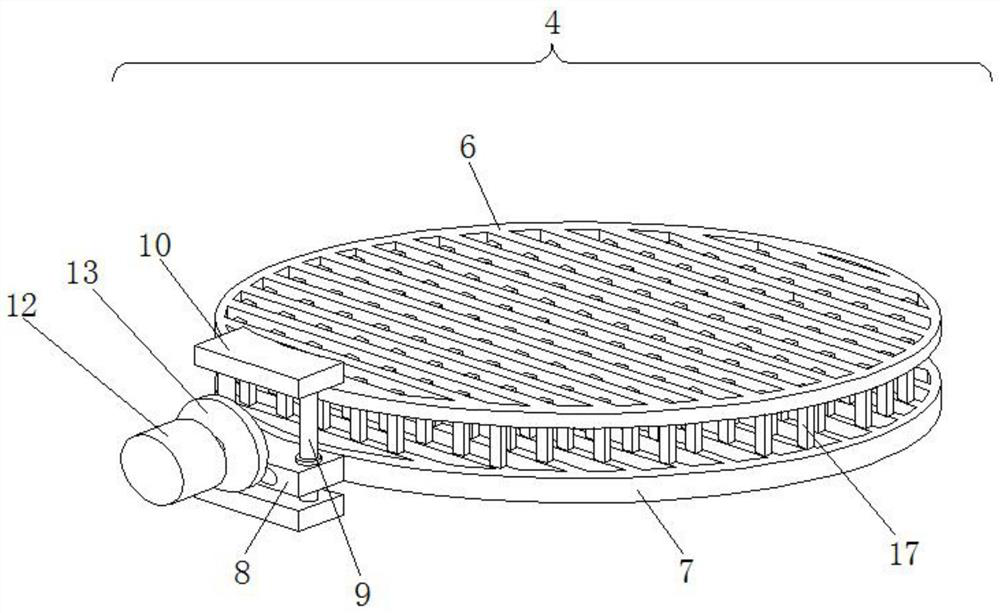

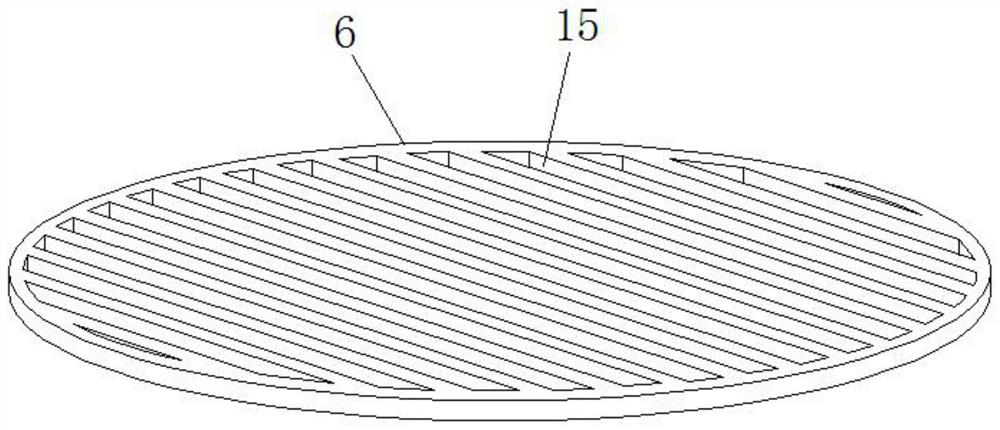

[0034] see Figure 1-6, a biomass combustion boiler with high combustion efficiency with an energy recovery link, comprising a boiler main body 1, an energy recovery conversion mechanism 2 is fixedly installed on one side of the boiler main body 1, and an internal upper end of the boiler main body 1 is provided with Combustion chamber 3, the bottom of the combustion chamber 3 is provided with a fire grate mechanism 4, the bottom of the fire grate mechanism 4 is provided with an ash chamber 5, and the fire grate mechanism 4 includes a fixed furnace fixedly installed at the bottom of the combustion chamber 3 The grate 6 and the movable grate 7 that are slidably installed directly under the fixed grate 6, a lifting frame 8 is fixedly installed on one side of the moving grate 7, and vertically arranged Slide bar 9, the upper and lower ends of two described slide bars 9 are all fixedly connected with the fixing seat 10 that is installed on the outer wall of ash chamber 5, and the o...

Embodiment example 2

[0040] see Figure 7 The energy recovery conversion mechanism 2 includes an outer box 18 fixedly installed on one side of the boiler body 1, a circulating water tank 19 is installed at the inner lower end of the outer box 18, and the top of the circulating water tank 19 passes through the outer box. The steam pipe 20 on the inner wall of 18 communicates with a heating box 21 arranged on the outer wall of the combustion chamber 3. The middle position of the steam pipe 20 is provided with an impeller 22, and the impeller 22 is connected by a rotating shaft 23 penetrating through the lower wall of the steam pipe 20. There is a driving gear 24, the driving gear 24 is meshed with a driven gear 25, and the driven gear 25 is sleeved on the output shaft of the generator 26 installed inside the outer box 18, and the generator 26 is electrically connected to There is a storage battery 27 installed inside the outer box 18, the bottom of the circulating water tank 19 is connected to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com