Anti-counterfeiting material, manufacturing method of anti-counterfeiting material, anti-counterfeiting element and anti-counterfeiting pigment

A production method and technology of anti-counterfeiting components, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, identification devices, etc., can solve the problems of single use range of films and no material use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

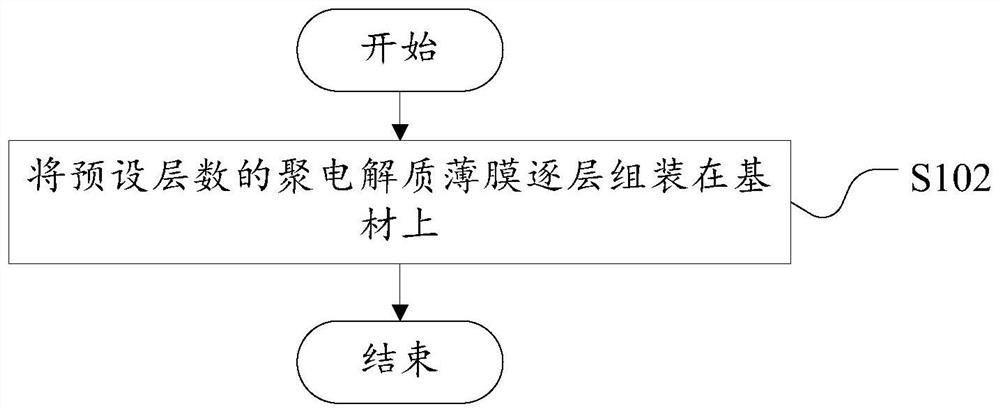

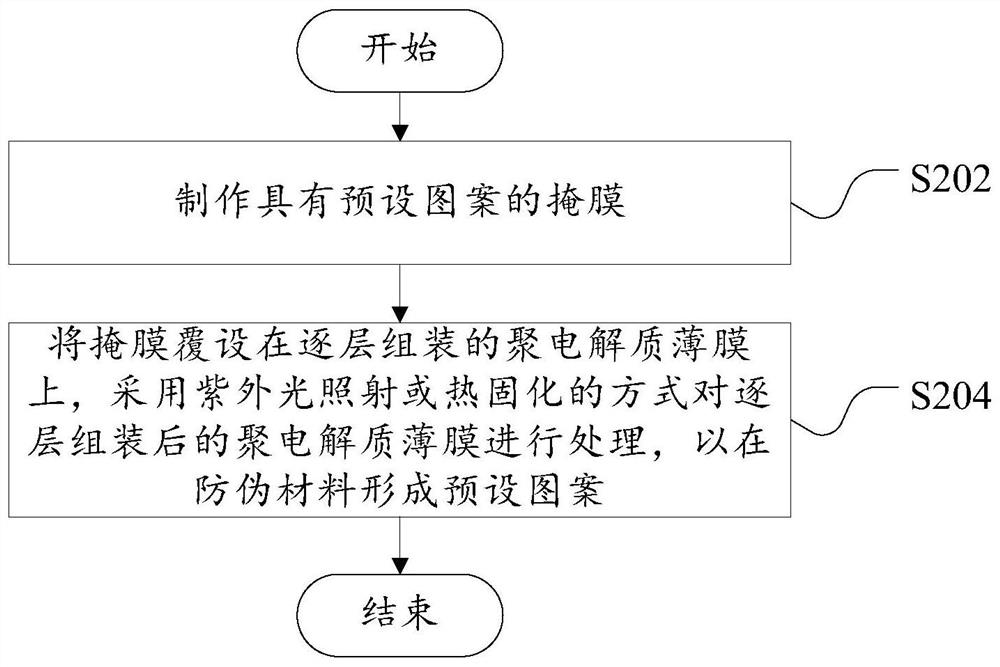

Method used

Image

Examples

Embodiment 1

[0065] This embodiment provides an anti-counterfeiting material, which can be the first color under natural light when the humidity value of the environment is less than the first humidity value; and when the humidity value of the environment is greater than or equal to the first humidity value, And when it is less than or equal to the second humidity value, in response to the change of the humidity value, at least two color changes occur on the basis of the first color, wherein at least two color changes can be identified under natural light.

[0066] The embodiment of the present application proposes an anti-counterfeiting material, which can display different colors under different humidity environments, so this characteristic can be used for counterfeiting. When authenticating products made of this material, change the humidity of the environment where the product is located, so as to determine the authenticity of the product by observing the color change of the finished pr...

Embodiment 2

[0094] This embodiment provides an anti-counterfeiting material. In addition to the technical features of Embodiment 1 above, this embodiment further includes the following technical features.

[0095] Polyelectrolyte films contain polyelectrolyte materials that are capable of undergoing volume changes under changes in humidity.

[0096] In this embodiment, the polyelectrolyte film includes a polyelectrolyte material, and the volume of the polyelectrolyte material can change under humidity changes. For example, when the humidity changes, the polyelectrolyte material will swell or deswell. Specifically, the polyelectrolyte material can When it comes into contact with liquid, it can swell, and then the volume increases. On the contrary, when it cannot touch the liquid, it can deswell, and then the volume decreases, that is, there is a volume change, and then a dynamic structural color is produced. Because the above color change is There is a line-corresponding relationship with...

Embodiment 3

[0098] This embodiment provides an anti-counterfeiting material. In addition to the technical features of any of the above embodiments, this embodiment further includes the following technical features.

[0099] Polyelectrolyte films include chitosan films and photoactive carboxymethylcellulose-azido derivative films.

[0100] In this embodiment, the polyelectrolyte film includes a chitosan film and a photoactive carboxymethylcellulose-azido derivative film, which further broadens the range of humidity that the anti-counterfeiting material can respond to, increases the color types that the anti-counterfeiting material can change, and improves the anti-counterfeiting effect. Material reliability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com