A kind of photocuring 3D printing dehumidification ceramic material and preparation method thereof

A technology of 3D printing and ceramic materials, which is applied in the field of light-curing 3D printing dehumidification ceramic materials and its preparation, can solve the problems of poor dehumidification effect, achieve the effects of widening the humidity range, rapid recycling, and improving dehumidification effect and dehumidification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

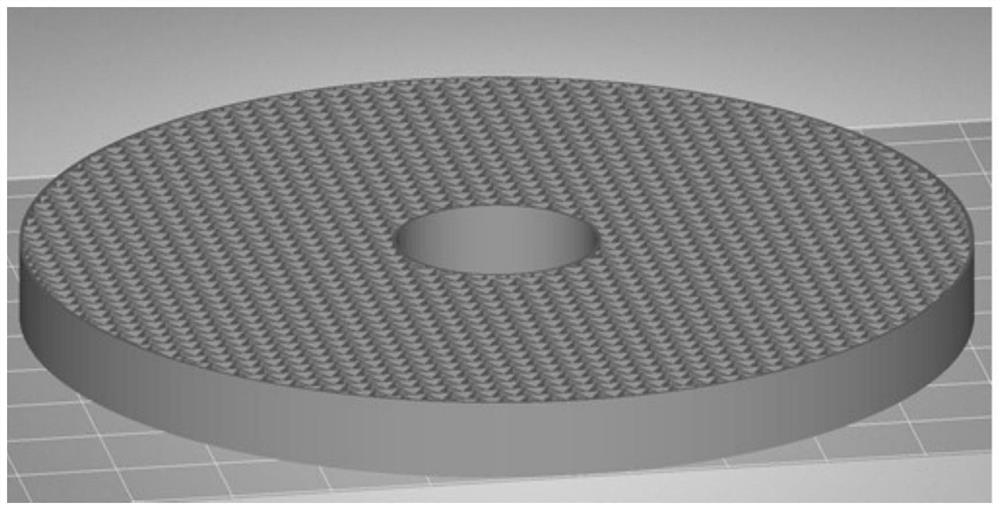

[0042] On the one hand, an embodiment of the present invention provides a method for preparing a photocuring 3D printing dehumidifying ceramic material, which includes the following steps:

[0043] 1) Preparation of photocuring 3D printing dehumidifying ceramic slurry: after mixing the 3D printing dehumidifying ceramic solid phase raw material with the 3D printing liquid phase solvent, the photocuring 3D printing dehumidifying ceramic slurry is obtained; wherein, in parts by weight, the photocuring 3D printing The printing dehumidifying ceramic slurry includes: 35-50 parts by weight of a strengthening agent, 1-25 parts by weight of a condensation agent, 1-15 parts by weight of a hydrophobic agent, and 30-50 parts by weight of a liquid phase solvent for 3D printing. Preferably, the photocurable 3D printing dehumidifying ceramic slurry further includes 5-9 parts by weight of an adsorbent.

[0044] Preferably, this step is specifically as follows: mechanically stirring the 3D pri...

Embodiment 1

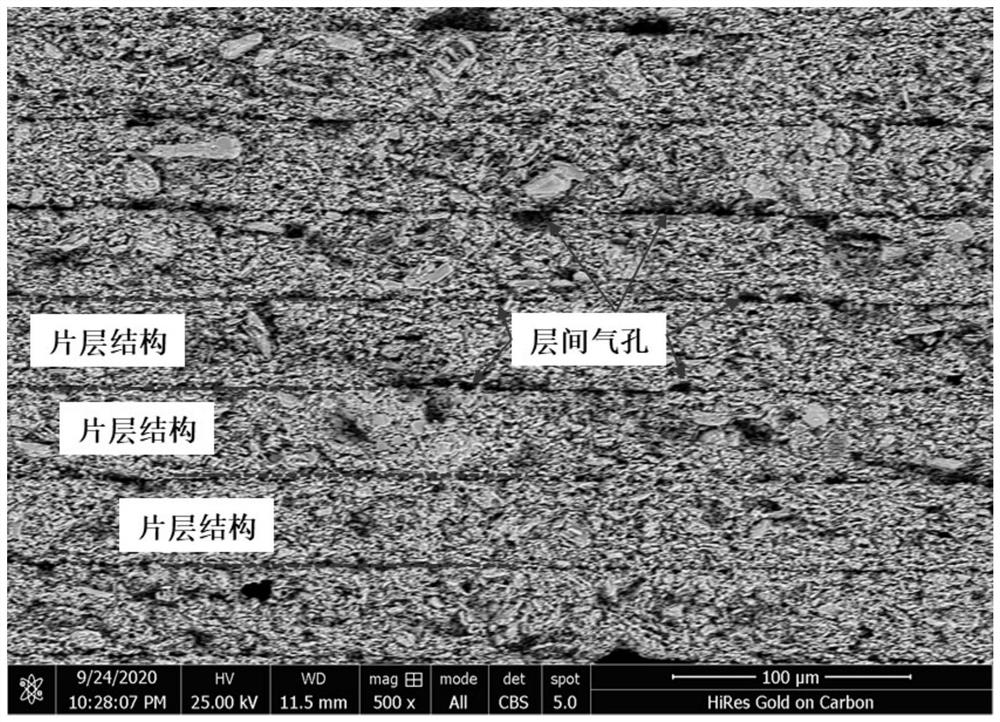

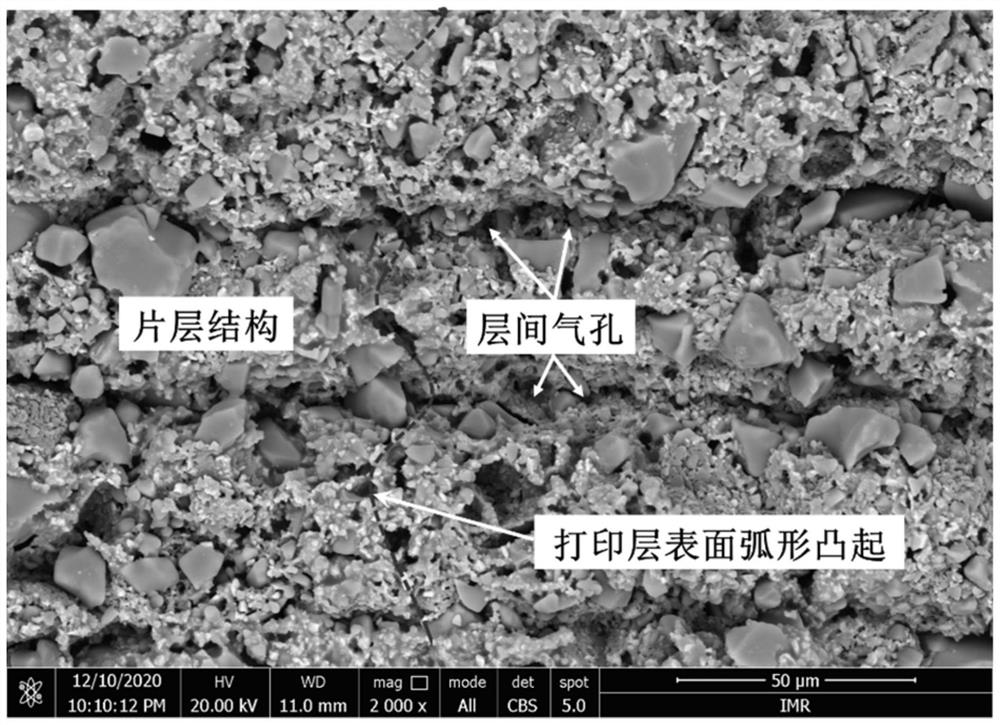

[0060] In this example, a light-curing 3D printing dehumidification ceramic material is prepared; wherein, the raw materials used and their parts by mass are as follows: 40 parts by weight of a strengthening agent, 20 parts by weight of a dew condensation agent, 5 parts by weight of a hydrophobic agent, and 5 parts by weight of an adsorbent parts, 30 parts by weight of the 3D printing liquid phase solvent (wherein, in the 3D printing liquid phase solvent: the volume ratio of the photosensitive resin and the diluent is 21:9).

[0061] Among them, the strengthening agent is made by mixing quartz powder, corundum powder and feldspar powder according to the mass ratio of 3:1:1. In addition, the particle size of the reinforcing agent was 100 μm, and the powder particle shape was ellipsoid. Condensing agent is Al 2 O 3 and TiO 2 It is mixed in a mass ratio of 6:4. In addition, the particle size of the condensing agent was 50 μm, and the particle shape of the powder was rhombus. ...

Embodiment 2

[0070] In this example, a light-curing 3D printing dehumidifying ceramic material is prepared; wherein, the raw materials used and their parts by weight are as follows: 35 parts by weight of a strengthening agent, 25 parts by weight of a dew condensation agent, 1 part by weight of a hydrophobic agent, and 9 parts by weight of an adsorbent parts, 30 parts by weight of the 3D printing liquid phase solvent (wherein, in the 3D printing liquid phase solvent: the volume ratio of the photosensitive resin and the diluent is 24:6).

[0071] Among them, the strengthening agent is made up of feldspar powder, biotite powder, and kaolinite powder mixed in a mass ratio of 4:2:1. In addition, the particle size of the reinforcing agent was 200 μm, and the powder particle shape was spherical. Condensing agent is Al 2 O 3 and SiO 2 It is mixed in a ratio of 2:1 by mass. In addition, the particle size of the condensing agent was 10 μm, and the particle shape of the powder was rhombus. The h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com