A rotor of a disc permanent magnet motor and a disc permanent magnet motor using the same

A permanent magnet motor and rotor technology, applied in magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of wrong polarity of permanent magnets, motor damage, troublesome assembly process, etc. The effect of magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

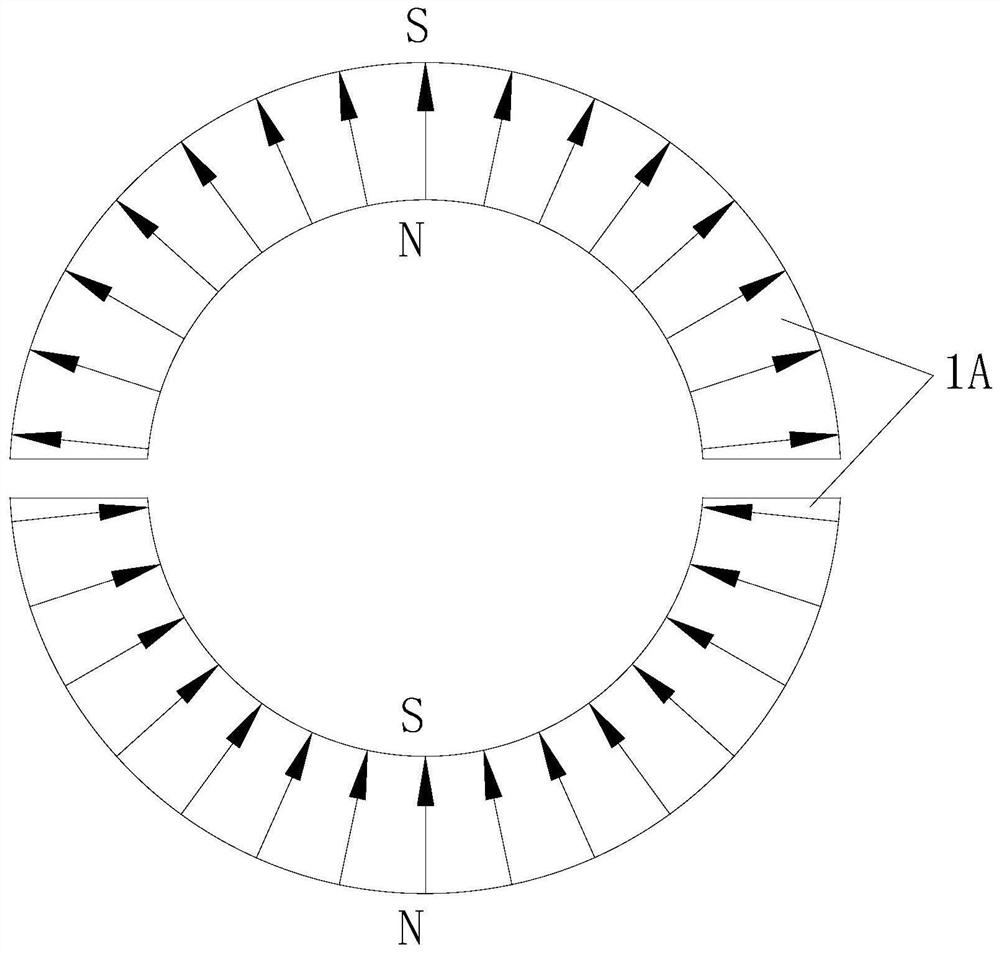

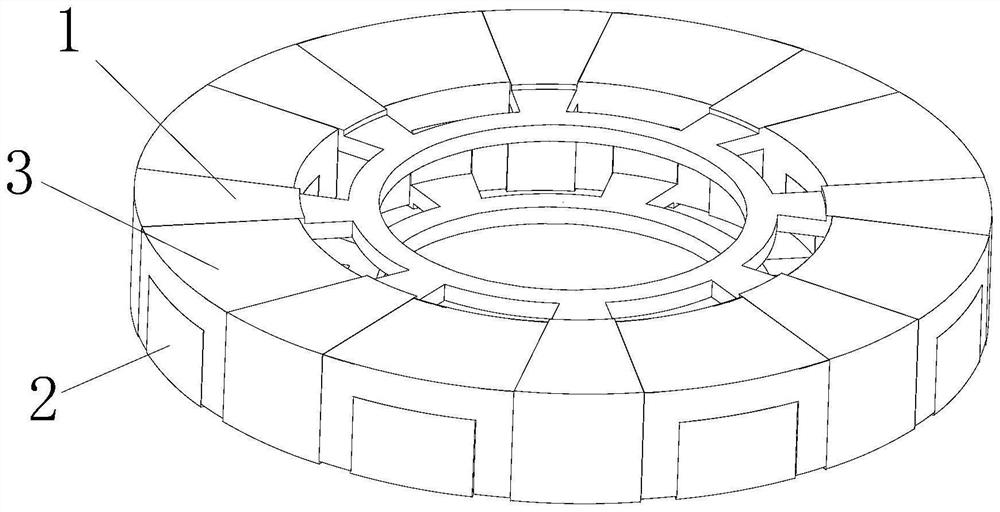

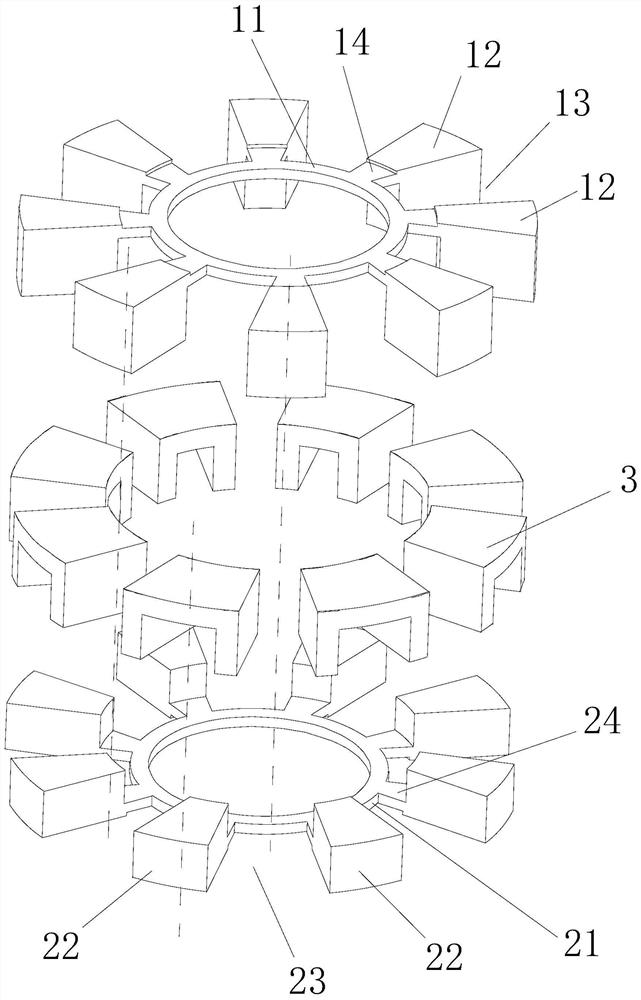

[0050] like Figure 2 to Figure 7 As shown, this embodiment provides a rotor of a disc permanent magnet motor, including a first rotor core 1, a second rotor core 2 and a number of magnetic tiles 3, and the first rotor core 1 includes a first annular ring 11 and several circumferentially spaced first magnetic conductive blocks 12 protruding from the outside of the first annular ring 11, a first groove 13 is formed between two adjacent first magnetic conductive blocks 12; the second rotor core 2. It includes a second annular ring 21 and a plurality of circumferentially spaced second magnetic conductive blocks 22 protruding from the outside of the second annular ring 21, and a second groove 23 is formed between two adjacent second magnetic conductive blocks 22. ; The first rotor core 1 and the second rotor core 2 are axially embedded, the first magnetic conductive block 12 is embedded in the second groove 23, and the second magnetic conductive block 22 is embedded in the first g...

Embodiment 2

[0059] like Figure 13 and Figure 14 As shown, this embodiment is modified on the basis of Embodiment 1. In this embodiment, the left magnetic steel 32 and the right magnetic steel 33 are inclined to the top magnetic steel 31, and the left magnetic steel 32 and the right magnetic steel 32 are inclined to the top magnetic steel 31. The angle formed between the magnet steel 33 and the top magnet steel 31 may be an obtuse angle or an acute angle.

Embodiment 3

[0061] like Figures 15 to 18 As shown, this embodiment is improved on the basis of Embodiment 1. In this embodiment, the top of the first magnetic conductive block 12 and the two sides of the first magnetic conductive block 12 are respectively convex. There is a first bump 5 , and the bottom surface of the first bump 5 abuts on the top surface of the magnetic tile 3 to limit the axial movement of the magnetic tile 3 ; The inner end portion 223 and the outer end portion 224 respectively protrude upward with second bumps 6 , the magnetic tile 3 is located between the two second bumps 6 , and the two second bumps 6 are used to limit The radial movement of the magnetic tile 3 can directly fix the magnetic tile 3 through the first bumps 5 and the second bumps 6, and does not need to be glued and fixed, which can simplify the assembly steps and improve the production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com