A garlic yellow baling harvester

A harvester and garlic yellow technology, which is applied in the direction of harvesters, balers, agricultural machinery and implements, etc., can solve the problems of dense distribution in pieces, unfavorable arrangement, bundling and harvesting, easy damage, and easy lodging of garlic yellow. , to achieve the effect of good support and plucking, neat and consistent garlic yellow bundles, and small damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

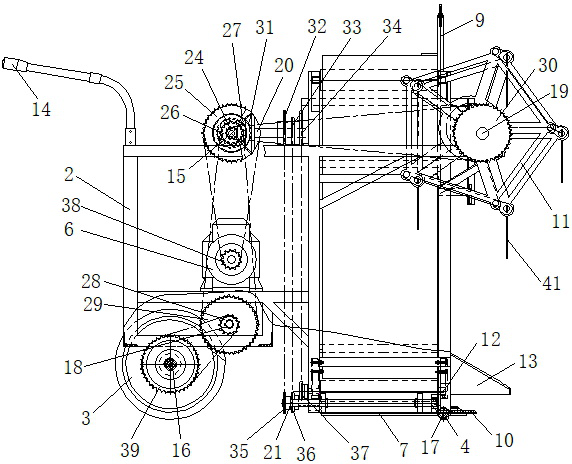

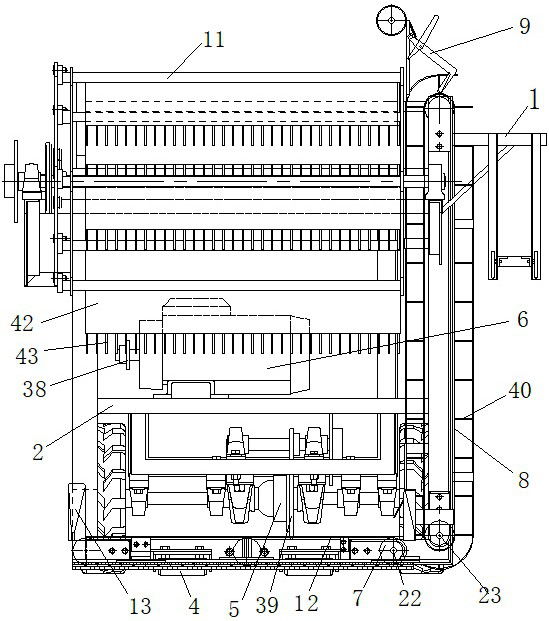

[0021] like figure 1 and figure 2 As shown, a garlic yellow baling harvester includes a collecting box support 1, a frame 2, a traveling wheel 3, a supporting wheel 4, a differential 5, an electric motor 6, a horizontal horizontal conveying device 7, a vertical conveying device 8, The baler 9, the cutter 10, the feeding wheel 11, the baffle plate 12, the crop divider 13 and the transmission mechanism are provided with a handle 14 at the rear and upper part of the frame, and the collecting box bracket 1 is arranged at the upper side of the frame 2, and the The frame 2 is fixedly connected by bolts, two traveling wheels 3 and two supporting wheels 4 are respectively installed, the axes of the two traveling wheels 3 are aligned, and they are respectively installed on the rear and lower sides of the frame 2 through bearings, and a differential is set between them. 5. The axes of the two supporting wheels 4 are aligned and installed on both sides of the front and lower sides of t...

Embodiment 2

[0027] like figure 1 and figure 2 As shown, a garlic yellow baling harvester includes a collecting box support 1, a frame 2, a traveling wheel 3, a supporting wheel 4, a differential 5, an electric motor 6, a horizontal horizontal conveying device 7, a vertical conveying device 8, The baler 9, the cutter 10, the feeding wheel 11, the baffle plate 12, the crop divider 13 and the transmission mechanism are provided with a handle 14 at the rear and upper part of the frame, and the collecting box bracket 1 is arranged at the upper side of the frame 2, and the The frame 2 is fixedly connected by bolts, two traveling wheels 3 and two supporting wheels 4 are respectively installed, the axes of the two traveling wheels 3 are aligned, and they are respectively installed on the rear and lower sides of the frame 2 through bearings, and a differential is set between them. 5. The axes of the two supporting wheels 4 are aligned and installed on both sides of the front and lower sides of t...

Embodiment 3

[0033] like figure 1 and figure 2 As shown, a garlic yellow baling harvester includes a collecting box support 1, a frame 2, a traveling wheel 3, a supporting wheel 4, a differential 5, an electric motor 6, a horizontal horizontal conveying device 7, a vertical conveying device 8, The baler 9, the cutter 10, the feeding wheel 11, the baffle plate 12, the crop divider 13 and the transmission mechanism are provided with a handle 14 at the rear and upper part of the frame, and the collecting box bracket 1 is arranged at the upper side of the frame 2, and the The frame 2 is fixedly connected by bolts, two traveling wheels 3 and two supporting wheels 4 are respectively installed, the axes of the two traveling wheels 3 are aligned, and they are respectively installed on the rear and lower sides of the frame 2 through bearings, and a differential is set between them. 5. The axes of the two supporting wheels 4 are aligned and installed on both sides of the front and lower sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com