Dust removal system for building engineering construction

A dust removal system and construction engineering technology, applied in construction, use of liquid separating agent, and filtration of dispersed particles, can solve problems such as high cost of use, increased water consumption, and difficult adjustment of the amount of water mist sprayed from the spray cylinder, etc., to achieve Good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

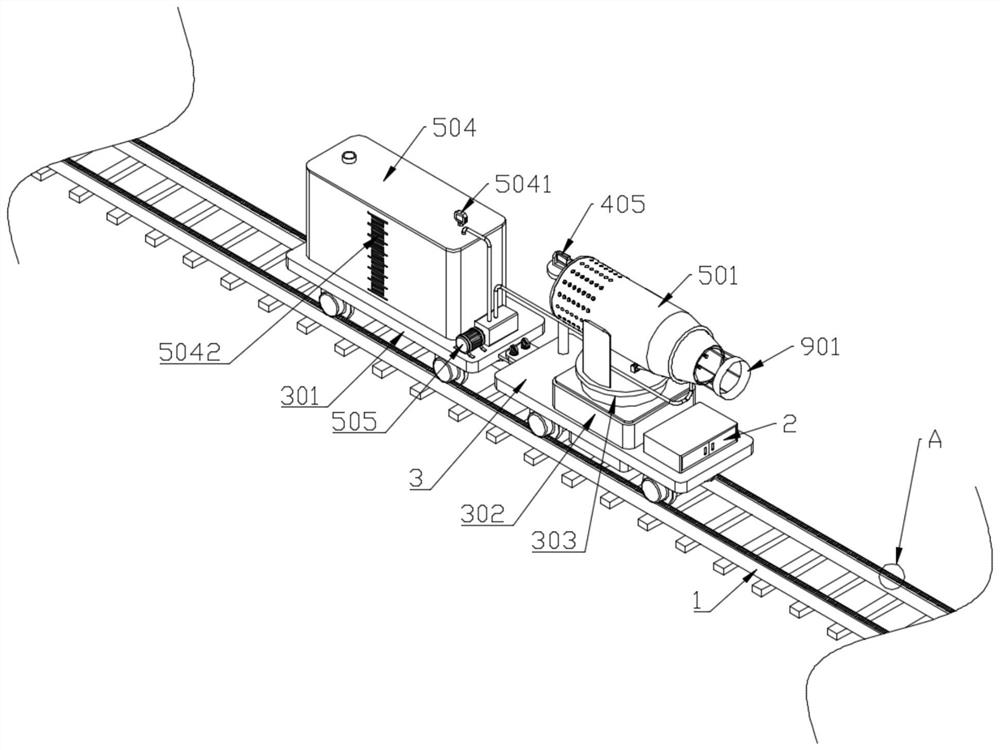

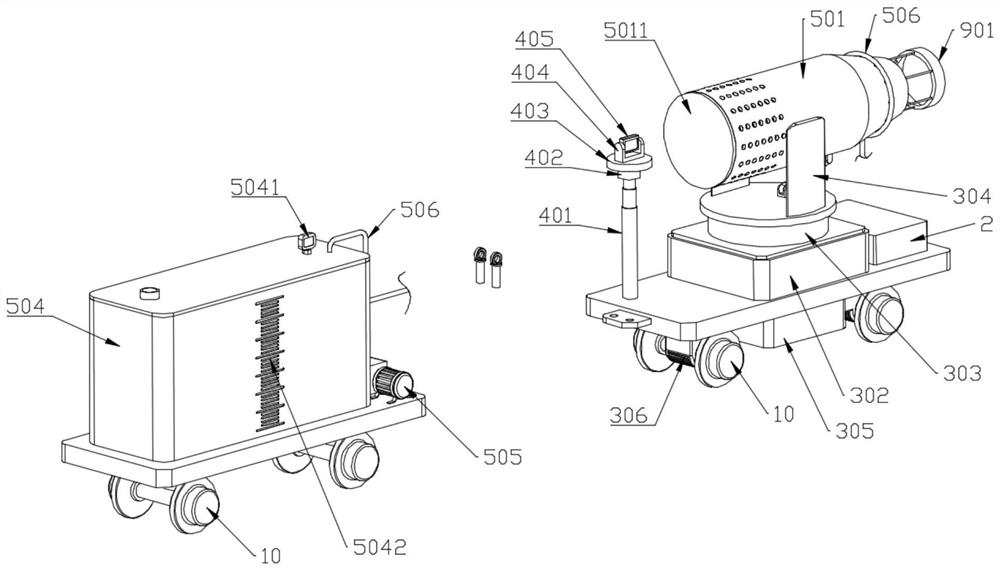

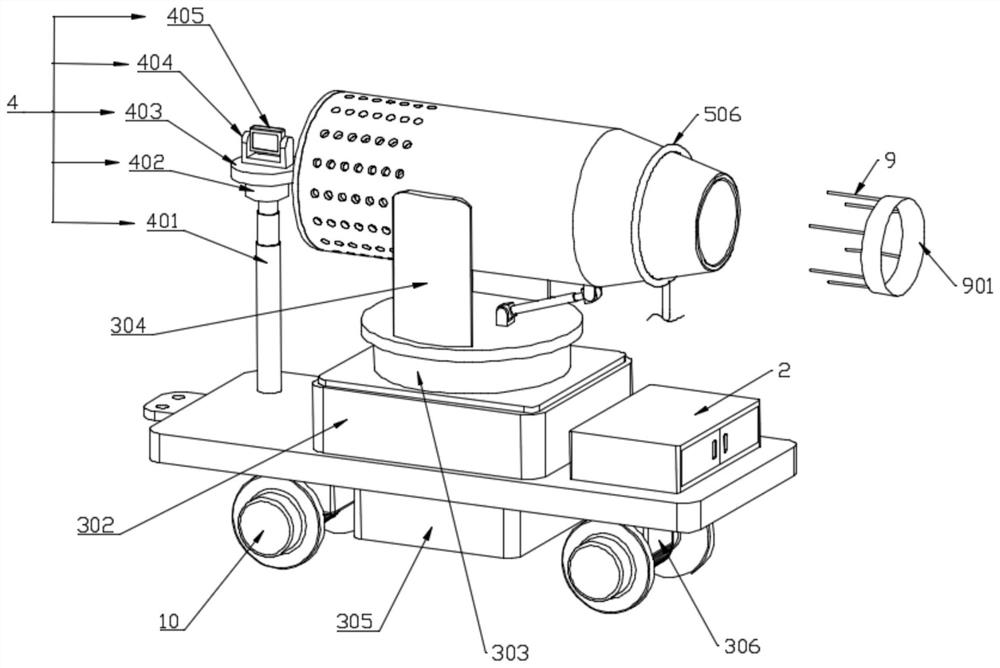

[0062] This embodiment provides a kind of dust removal system for building engineering construction, with reference to Figure 1-14 : Including track 1, vehicle assembly, purification assembly and PLC control box 2.

[0063] It should be noted that the PLC control box 2 is set on the tractor 3 , and the electrical components in the present invention are all controlled by the PLC control box 2 and powered by the battery 305 .

[0064] Track 1 is pre-laid on the ground in the specified path. Because the complex working conditions of the construction site will make the surface of the track 1 become wet, so that the tractor 3 and the trailer 301 will slip when they are running on the track 1 (or the tractor 3 and the trailer 301 will be parked on the track 1) (In addition, when the fog cannon assembly 5 sprays water mist, there is a possibility that the track 1 will become wet); therefore, it is necessary to evenly arrange the anti-slip embossing 101 on the surface of the track 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com