Four-jaw chuck for laser pipe cutting machine

A four-jaw chuck and laser cutting technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large installation space, difficult installation and disassembly, and small jaw travel, so as to improve production efficiency and purchase The effect of less time and large jaw stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

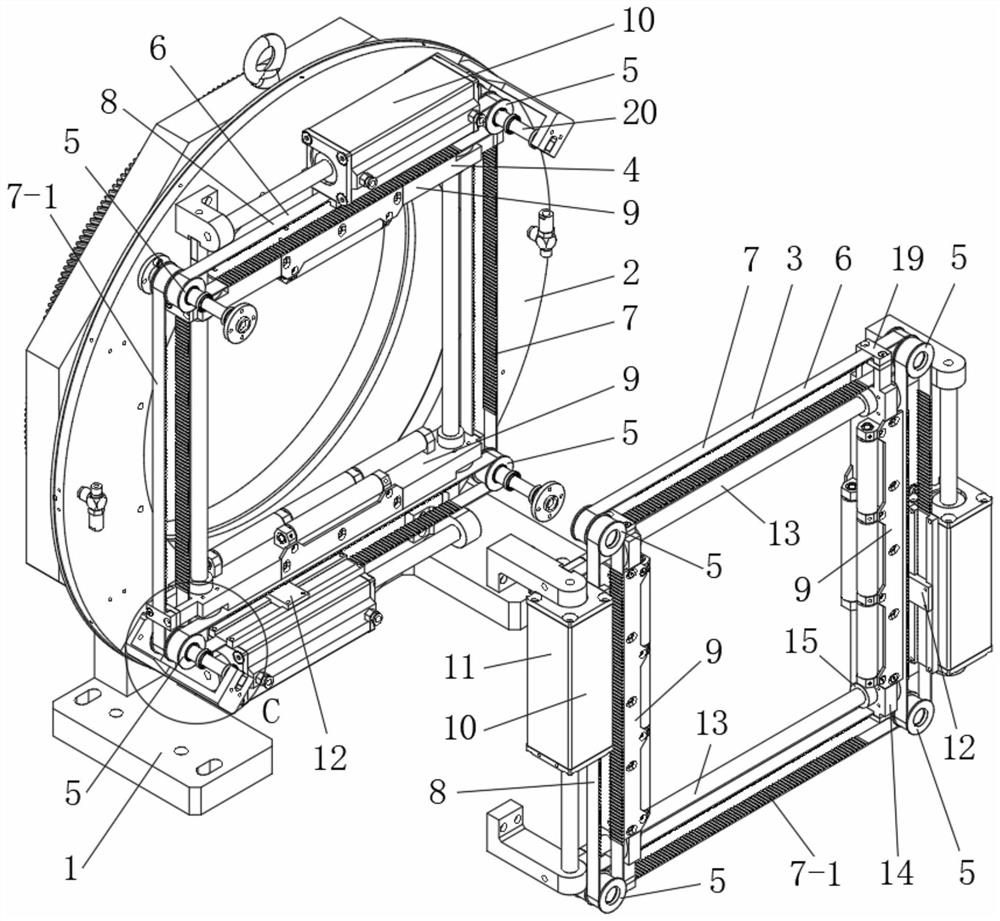

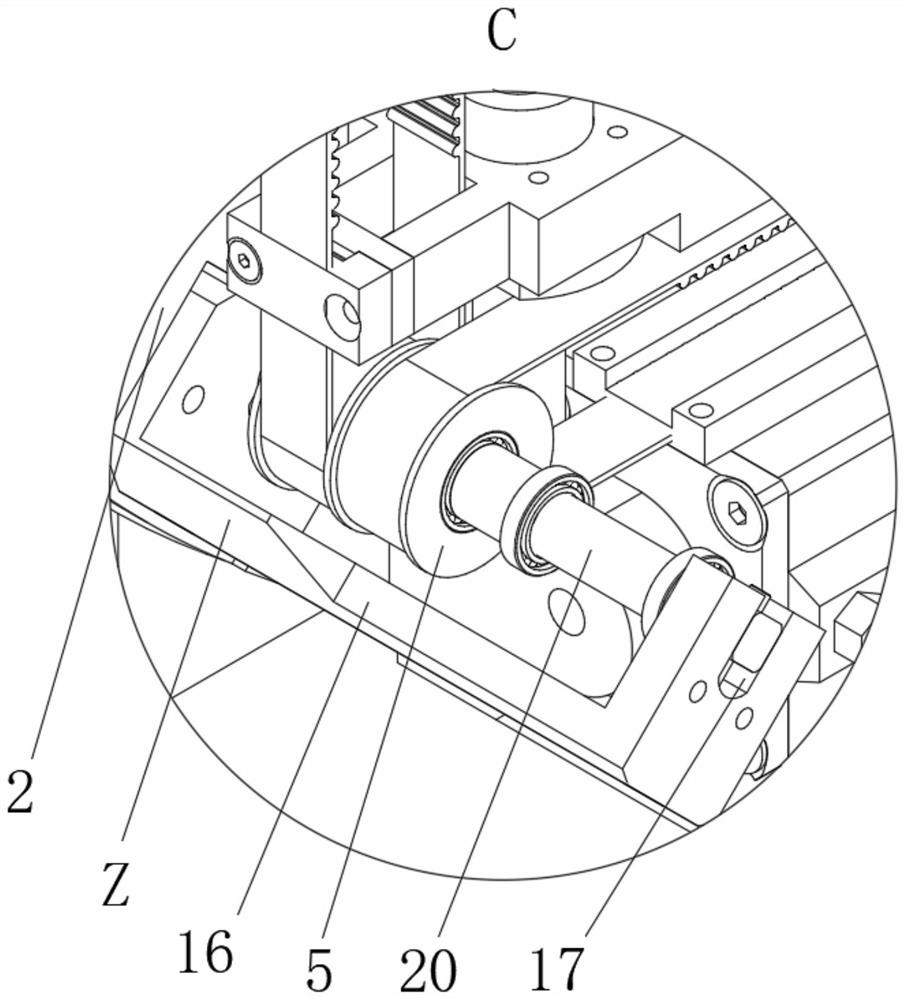

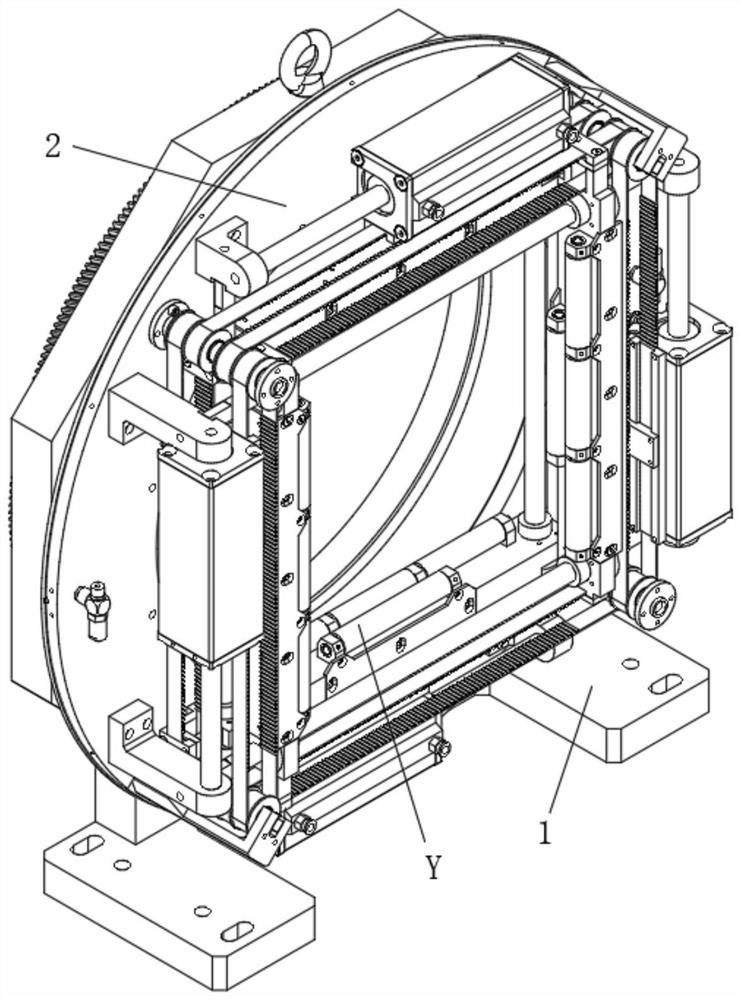

[0026] like Figure 1-6 , a four-jaw chuck for a laser pipe cutting machine in this embodiment includes a fixed seat 1, on which a turntable 2 is rotated, and the front side of the turntable 2 is respectively provided with horizontal and vertical clamping devices 3, 4, the horizontal and vertical clamping devices 3, 4 each include four runners 5 arranged at four corners, wherein any three pairs of adjacent runners 5 are driven by ring-shaped flexible members 6 Cooperate, wherein, the two flexible pieces 6 that are oppositely arranged are the first and second driven flexible pieces 7, 7-1 respectively, and the remaining flexible piece 6 is the active flexible piece 8, and the first driven flexible piece 6 is the active flexible piece 8. between the outer side of the flexible piece 7 and the inner side of the second driven flexible piece 7-1, and between the inner side of the first driven flexible piece 7 and the second driven flexible piece 7-1 The pressure roller assembly 9 i...

Embodiment 2

[0034] A working method of the four-jaw chuck described in Embodiment 1, comprising the following steps:

[0035] The driving device 10 drives the active flexible member 8 to move, and simultaneously drives the first and second driven flexible members 7 and 7-1 to move synchronously. The outer side and the inner side of the second driven flexible member 7-1 move in the same direction, and the inner side of the first driven flexible member 7 and the second driven flexible member 7-1 move in the same direction. The outer sides move in the same direction. Therefore, a pair of pressure roller assemblies 9 move in the opposite direction. When a pair of pressure roller assemblies 9 move in a straight line toward each other, the pipe material can be clamped, otherwise, the pipe material can be loosened. , a pair of pressing roller assemblies 9 of the lateral clamping device 3 is used for laterally clamping or loosening the pipe material, and a pair of pressing roller assemblies 9 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com