Continuous electrical pipe manufacturing production equipment

A technology for production equipment and electric pipes, which is applied in the field of continuous electric pipe manufacturing production equipment, can solve the problems of pipe body cutting offset, pipes cannot be connected, pipe body bending, etc., and achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

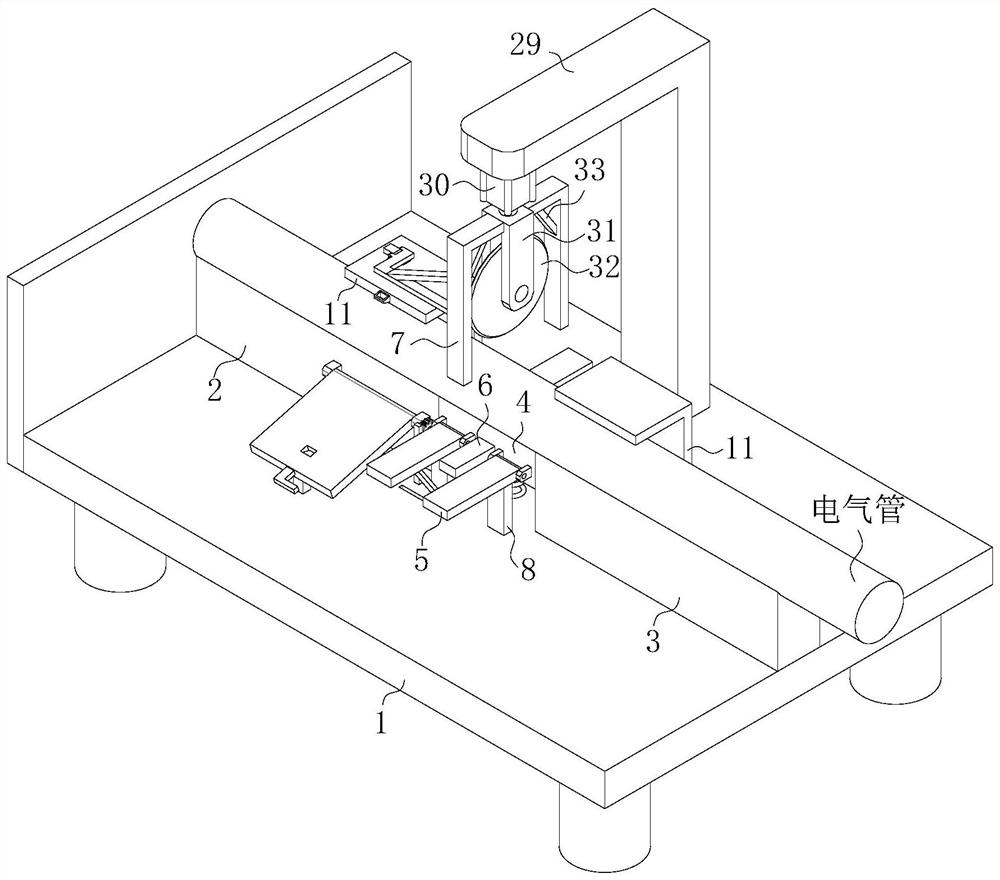

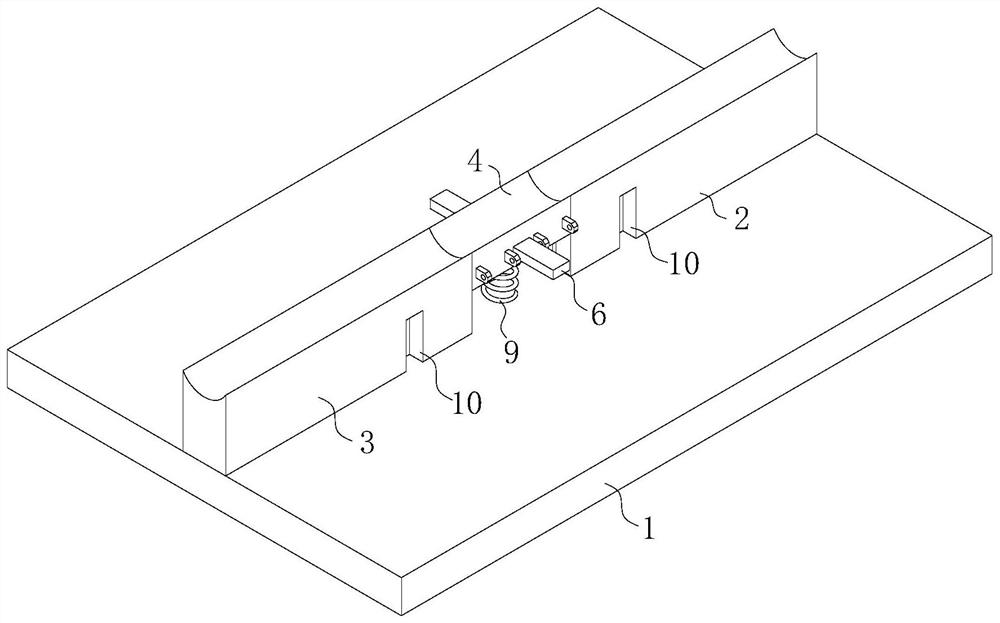

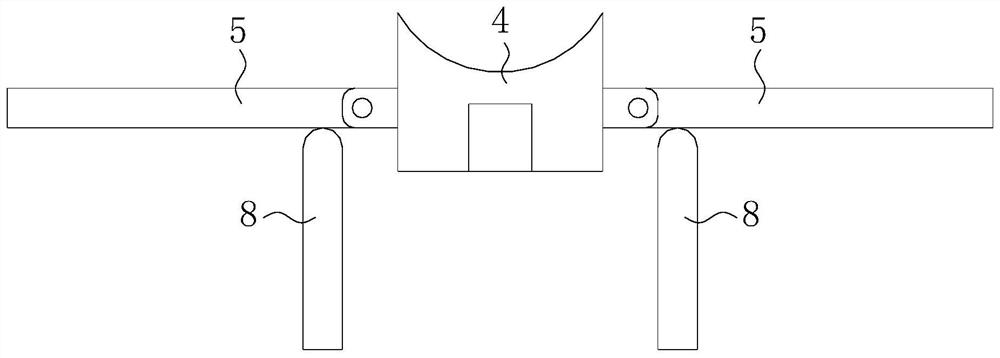

[0034] see Figure 1-9 , the present invention provides a technical solution: a continuous electric pipe manufacturing production equipment, including a base plate 1, a cutting mechanism is provided on the top and rear side of the base plate 1, and a first carrying platform 2 is fixedly connected to the top of the base plate 1 and the second carrying platform 3, the first carrying platform 2 and the second carrying platform 3 adjacent side walls are jointly vertically slidably connected with a third carrying platform 4, and the third carrying platform 4 is located directly below the cutting mechanism Two first splints 5 are rotatably connected to the front and rear side walls of the third carrying platform 4, and the two first splints 5 on the same side are arranged symmetrically with respect to the cutting mechanism. Above the bottom plate 1, there are A driving mechanism, the driving mechanism is used to drive the third carrying platform 4 to move downward when the cutting m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com