Electric automobile electro-hydraulic composite braking system based on hub motor driving and front and rear axle braking force distribution method

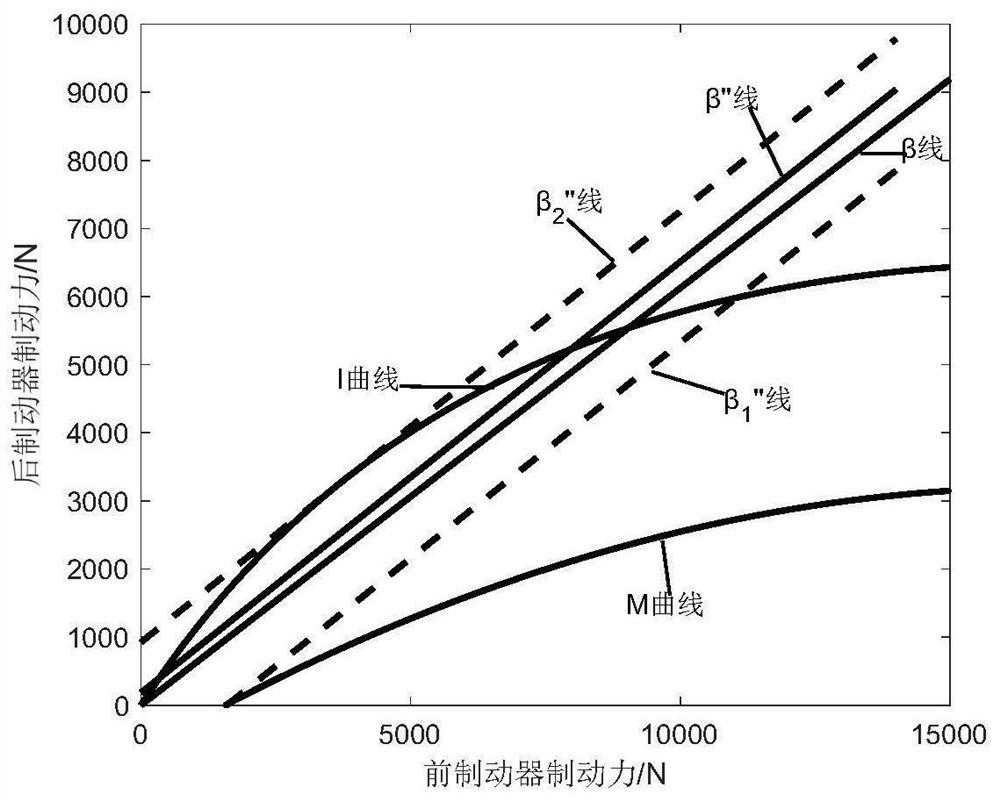

A braking force distribution, electro-hydraulic compound technology, applied in electric braking system, electric vehicle charging technology, electric vehicle, etc., can solve the problem that the rear axle braking force distribution line β″ may appear above the original vehicle β line and lose steering. ability, little consideration, etc., to achieve the effects of reasonable and feasible control methods, reducing the tendency to lock first, strong typicality and generality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

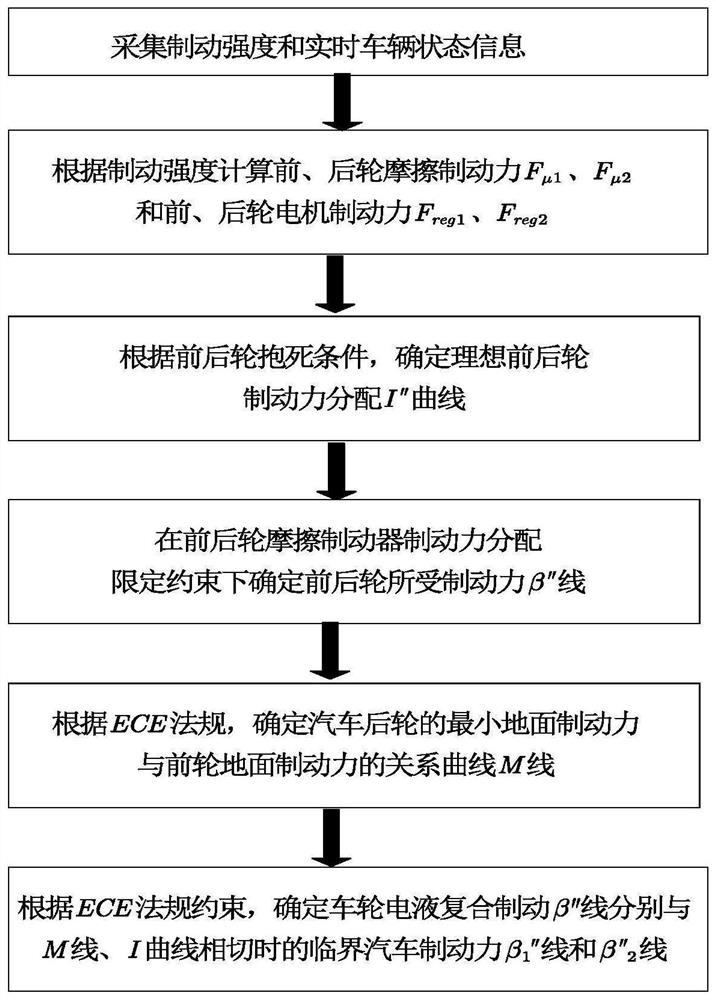

Method used

Image

Examples

Embodiment 1

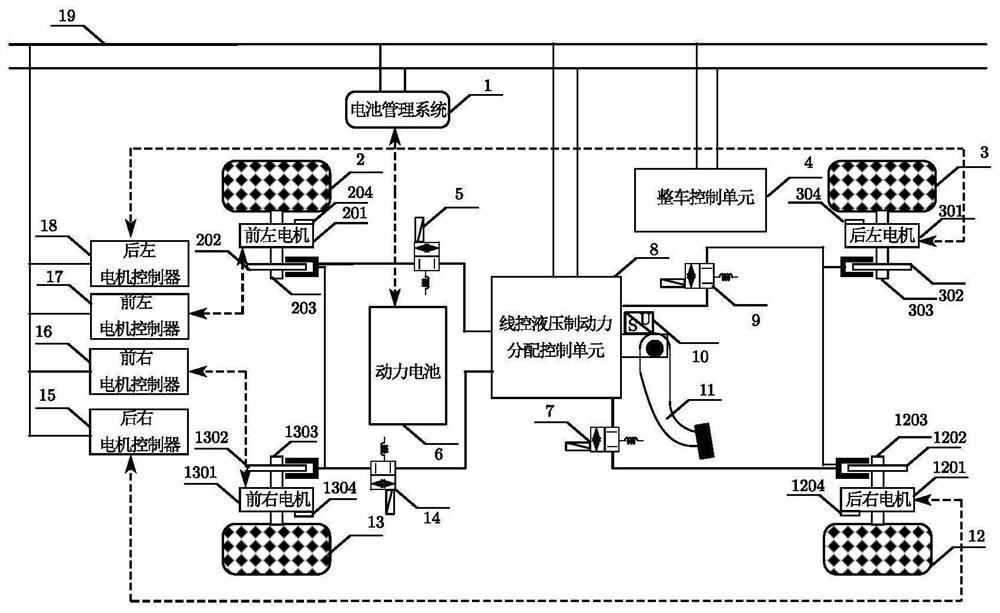

[0094] like figure 1 As shown, the present invention discloses a four-wheel electro-hydraulic composite braking system for electric vehicles driven by in-wheel motors, including a hydraulic friction braking module, a motor regenerative braking module, an energy management module and a vehicle control module; The friction braking module includes a vehicle control unit 4, a brake pedal 11, a wire-controlled hydraulic braking force distribution control unit 8, a front left solenoid valve 5, a rear left solenoid valve 9, a rear right solenoid valve 7, a front right solenoid valve 14 and Brake pedal displacement sensor 10, etc.; the vehicle control unit 4 is electrically connected to the CAN line 19, receives signals from the brake pedal displacement sensor 10, speed sensors 204, 304, 1204, and 1304, and judges the state of the vehicle in real time through analysis and synthesis , determine the required braking force, and then distribute the regenerative braking force of the motor ...

Embodiment 2

[0132] The invention discloses an electric vehicle front wheel electro-hydraulic composite braking system driven by a hub motor, which specifically includes: 1. a battery management system; 2. the front left wheel, 201, the front left hub motor, 202, the front left brake Disk, 203, front left axle, 204, front left motor speed sensor; 3, rear left wheel; 4, vehicle control unit; 5, front left solenoid valve; 6, power battery; 7, rear right solenoid valve; 8, 9. Rear left solenoid valve; 10. Brake pedal displacement sensor; 11. Brake pedal; 12. Rear right wheel; 13. Front right wheel, 1301. Front right hub motor, 1302 1303, front right axle, 1304, front right motor speed sensor; 14, front right solenoid valve; 15, front right motor controller; 16, front left motor controller; 17, CAN line. The difference from Example 1 is that the electro-hydraulic brake system described in this embodiment adopts the electro-hydraulic brake system for the front wheels, such as Figure 4 shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com