Inverted U-shaped integrated workbench of transparent film three-dimensional packaging machine

A packaging machine and transparent film technology, applied in the field of inverted U-shaped integrated workbench of transparent film three-dimensional packaging machine, can solve the problems of low production efficiency and inconvenient installation and debugging of transparent film three-dimensional packaging machine, and achieve convenient and fast positioning and module The effect of clear relationship between automated assembly and part assembly, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

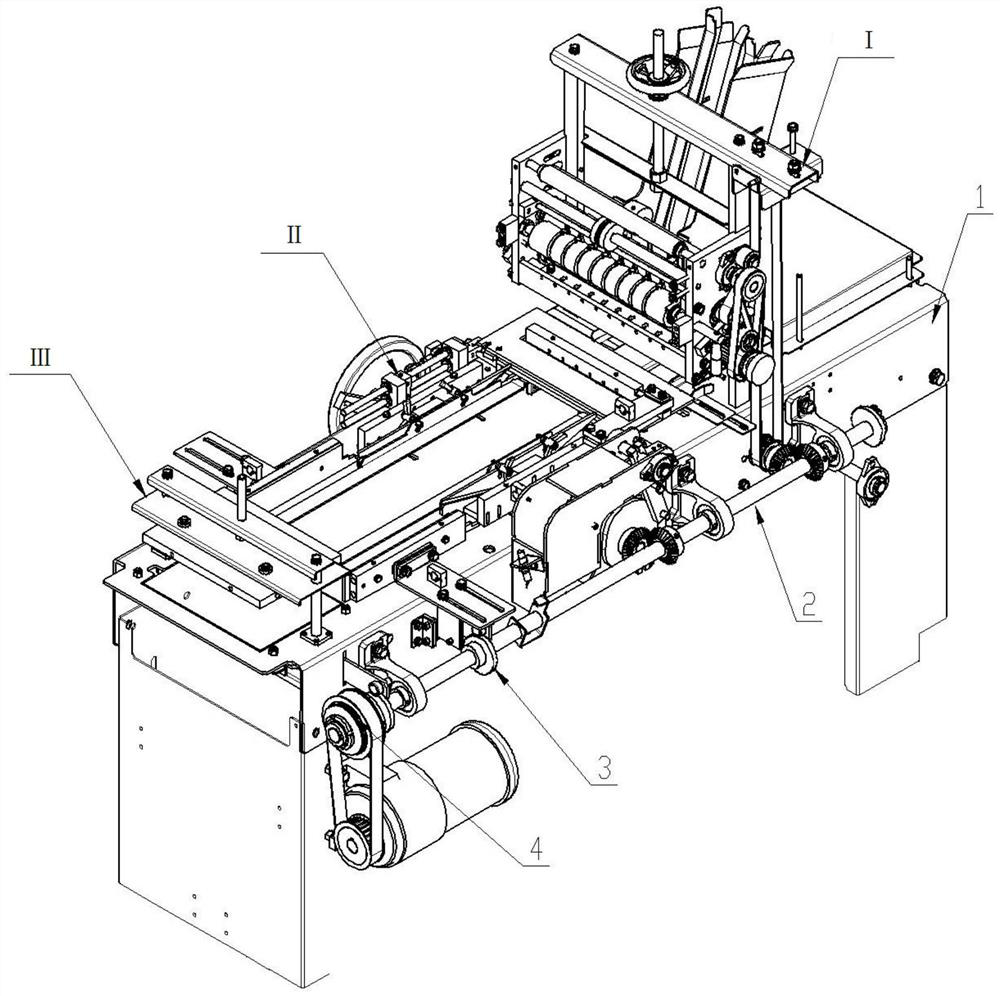

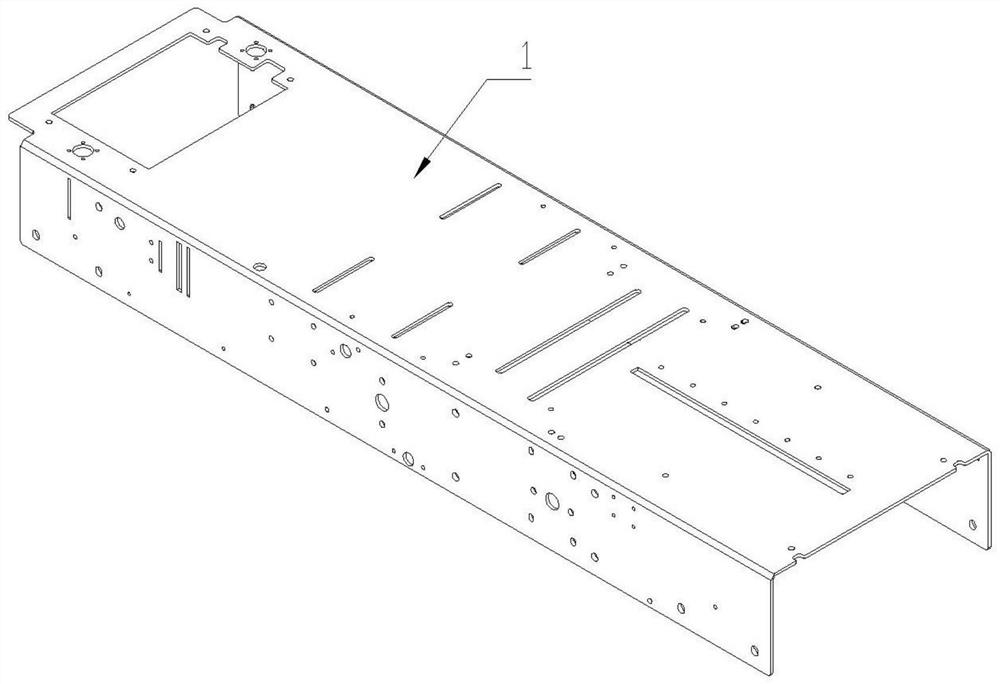

[0025] see Figure 1-Figure 2 , an inverted U-shaped integrated workbench for a transparent film three-dimensional packaging machine, comprising a large flat plate 1 having a plurality of mounting holes and mounting grooves formed by laser cutting; Bending down to form an inverted U-shaped cross-section; the large flat plate 1 passes through the installation holes and / or installation grooves from one side to the other to fix the functional parts in sequence, and the functional parts are connected to each other. Not directly fixed or positioned.

[0026] In this example, see figure 1 , the main shaft 2 of the transparent film three-dimensional packaging machine is arranged and fixed along the bending part of the large flat plate 1, and several cams 3 are fixed on the main shaft 2, and key grooves for determining the design angle are provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com