Textile fabric conveying and winding machine

A technology of textile fabrics and machinery, which is applied in the field of textile fabric conveying and winding machinery, which can solve the problems of fabric wrinkles, poor fabric rolling effect, and easy wrinkles and offsets of fabrics, so as to avoid wrinkles, ensure the smoothness of fabrics, and ensure the collection The effect of the volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

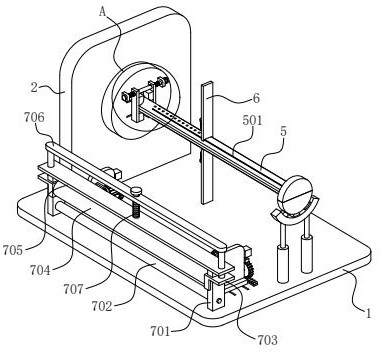

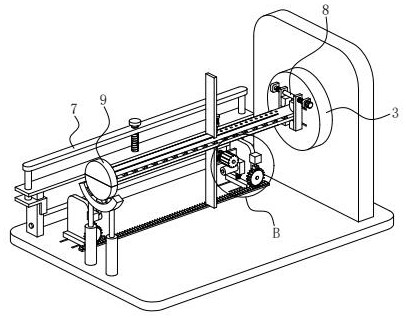

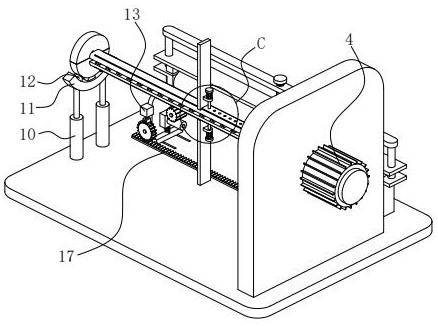

[0027] like Figure 1 to Figure 3As shown, this embodiment provides a textile fabric conveying and winding machine, including a horizontal bottom plate 1, a vertical plate 2 is fixedly installed on the bottom plate 1, and a vertical disk 3 is rotatably installed on the surface of the vertical plate 2. A horizontal drive motor 4 is fixedly installed on the straight plate 2 through the motor seat, and the output shaft of the drive motor 4 is fixedly connected with the disc 3; The bar-shaped splint 5, the bar-shaped splint 5 is perpendicular to the disc 3 and is slidably matched with the disc 3 along the radial direction of the disc 3; A strip baffle 6 perpendicular to the strip splint 5 is slidably installed on the upper part through the strip groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com