High-adhesion phosphoric acid modified resin and preparation method thereof

A technology of high adhesion and modified resin, which is applied in the field of polyurethane, can solve the problems of poor adhesion of polyurethane, and achieve the effect of strong adhesion and obvious competitive advantage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

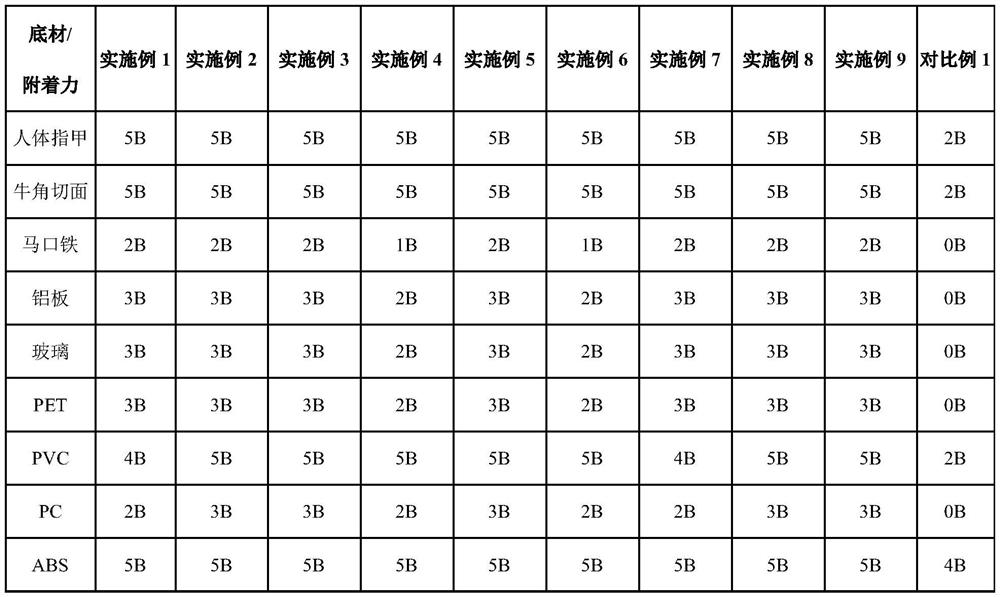

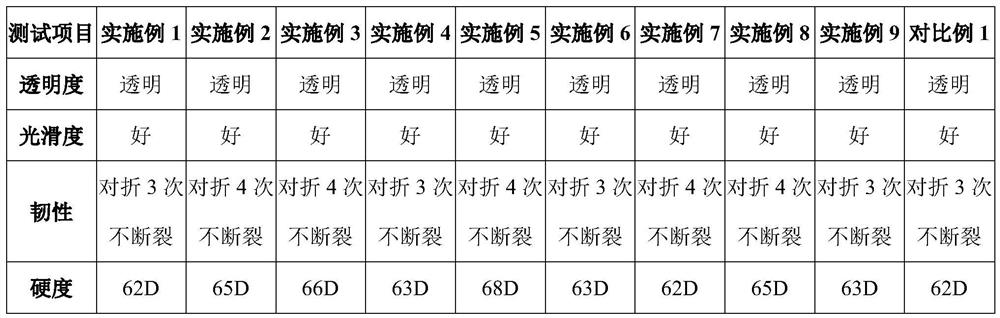

Examples

Embodiment 1

[0029] A kind of preparation method of the phosphoric acid modified resin of high adhesion, comprises the steps:

[0030] (1) First pump the reaction vessel until the air pressure is a negative pressure, feed nitrogen, put in 186g of ethylene glycol and 0.1g of antioxidant TPP, heat to 110°C for dehydration for 1 hour, add 142g of phosphorus pentoxide in 5 times, The temperature was kept at 115° C. for 3 hours to obtain polyester polyols containing phosphoric acid groups;

[0031] (2) 328g of polyester polyol obtained by step (1) and IPDI 666g were dropped into the reaction vessel and stirred for 17 minutes, then 0.2g of catalyst T12 was dropped into the reaction vessel, kept at a constant temperature of 75°C for 3 hours, and then dropped into 360g of hydroxyethyl acrylate, 0.5 g of polymerization inhibitor MEHQ was kept at a constant temperature of 75°C for 4 hours, and discharged after cooling down to 60°C to obtain polyurethane acrylate with a phosphoric acid structure of h...

Embodiment 2

[0033] A kind of preparation method of the phosphoric acid modified resin of high adhesion, comprises the steps:

[0034] (1) First pump the reaction vessel until the air pressure is a negative pressure, feed nitrogen, put in 1.4 cyclohexanedimethanol 432g and antioxidant TPP 0.1g, heat to 110°C for dehydration for 1 hour, and divide phosphorus pentoxide 142g into 5 Once added, the temperature was kept at 115°C for 3 hours to obtain a polyester polyol containing phosphoric acid groups;

[0035] (2) 574g of polyester polyol obtained in step (1) and IPDI 666g were dropped into the reaction vessel and stirred for 17 minutes, then 0.2g of the catalyst stannous octoate was dropped into the reaction vessel, kept at a constant temperature of 75°C for 3 hours, and then dropped into hydroxyethyl acrylate 360g, 0.5g of polymerization inhibitor MEHQ kept at a constant temperature of 75°C for 4 hours, cooled to 60°C and discharged to obtain polyurethane acrylate with phosphoric acid struc...

Embodiment 3

[0037] A kind of preparation method of the phosphoric acid modified resin of high adhesion, comprises the steps:

[0038] (1) First pump the container until the air pressure is a negative pressure, feed in nitrogen, put in 750g of PTMEG250 and 0.1g of antioxidant TPP, heat to 110°C for dehydration for 1 hour, add 142g of phosphorus pentoxide in 5 times, and the temperature is at 115°C ℃ heat preservation for 3 hours, heat preservation until the measured acid value reaches the target value, and discharge to obtain polyester polyol containing phosphoric acid groups;

[0039](2) Put 892g of polyester polyol and IPDI 666g obtained in step (1) into a reaction vessel and stir for 17 minutes, then put 0.8g of catalyst bismuth neodecanoate into the reaction vessel, keep a constant temperature of 75°C for 3 hours, and then drop into hydroxyethyl acrylate 360g of ester and 0.5g of polymerization inhibitor MEHQ were kept at a constant temperature of 75°C for 4 hours, and discharged after...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap