Textile fabric guiding device

A material guiding device and technology for textile fabrics, which are applied in textiles and papermaking, fabric surface trimming, thin material processing, etc., can solve the problems of affecting processing, uneven processing of fabrics, secondary folds of textiles, etc., to promote flow, facilitate internal and external The exchange of air flow, the effect of increasing the friction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

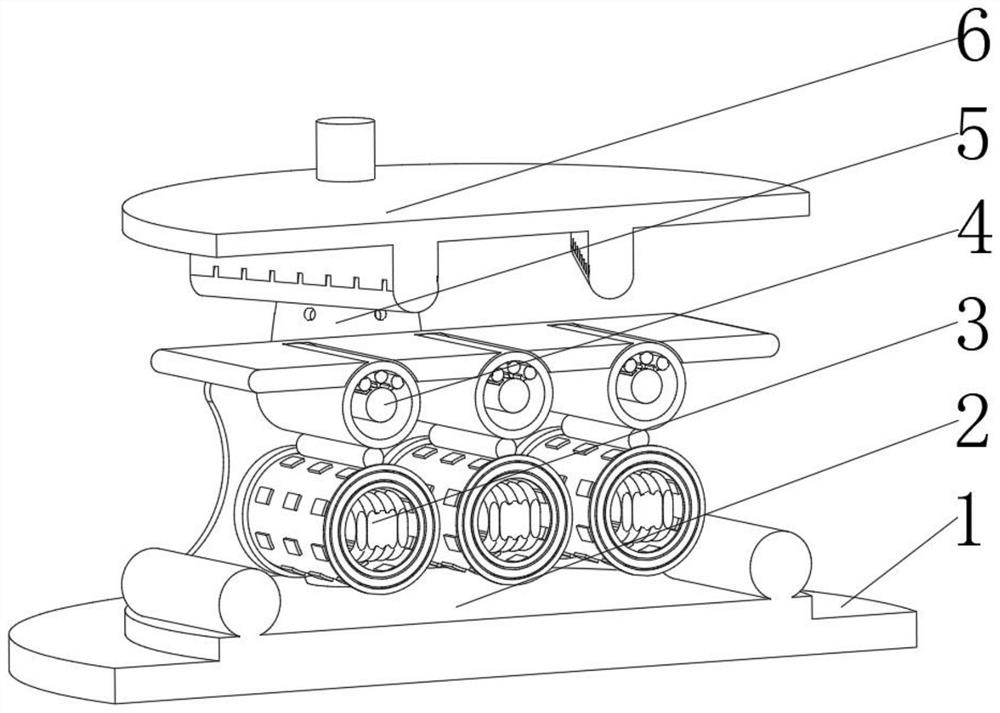

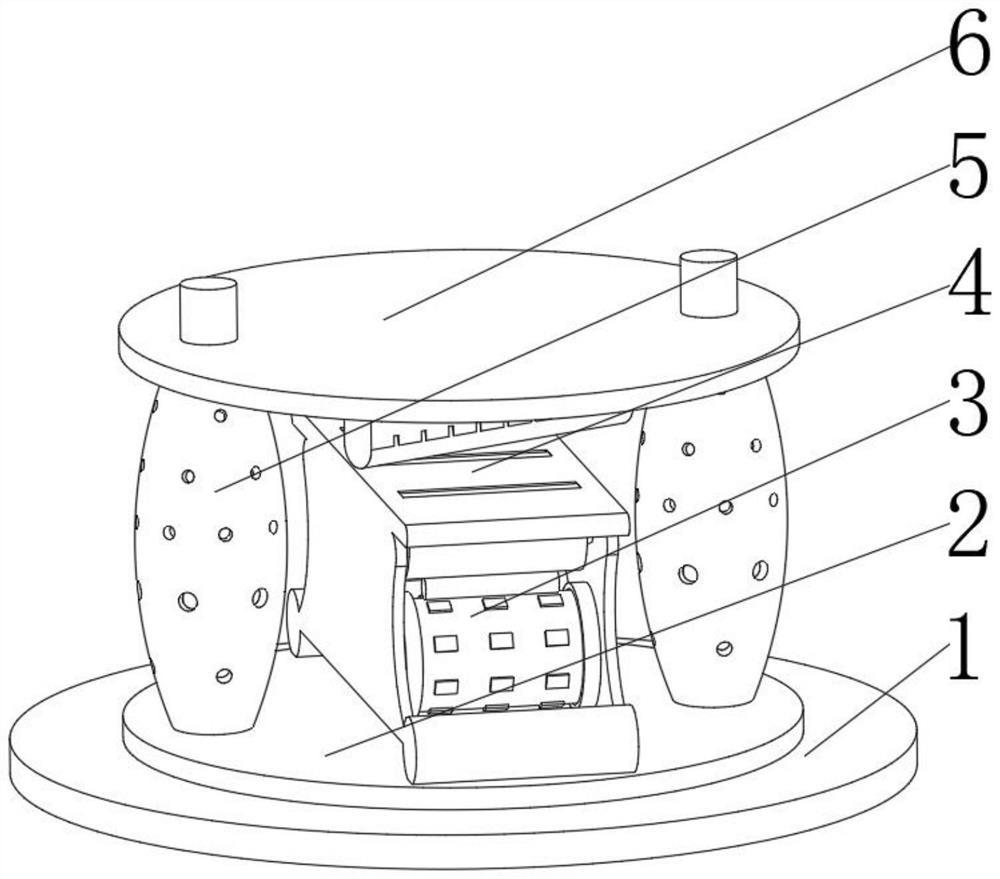

[0041] see Figure 1-6 , the present invention provides a technical solution: a textile material guide device, specifically comprising:

[0042] Seat plate 1, the seat plate 1 has a circular plate body, a disc seat 2 installed on the top of the circular plate body, a heating device 3 installed on the top of the disc seat 2, and a heating device 3 installed on the top The material guide plate 4, and the support device 5 installed on the top of the circular plate body and positioned at the front and back of the disc seat 2, and the flat pressing device 6 installed on the top of the support device 5, the material guide plate 4 includes:

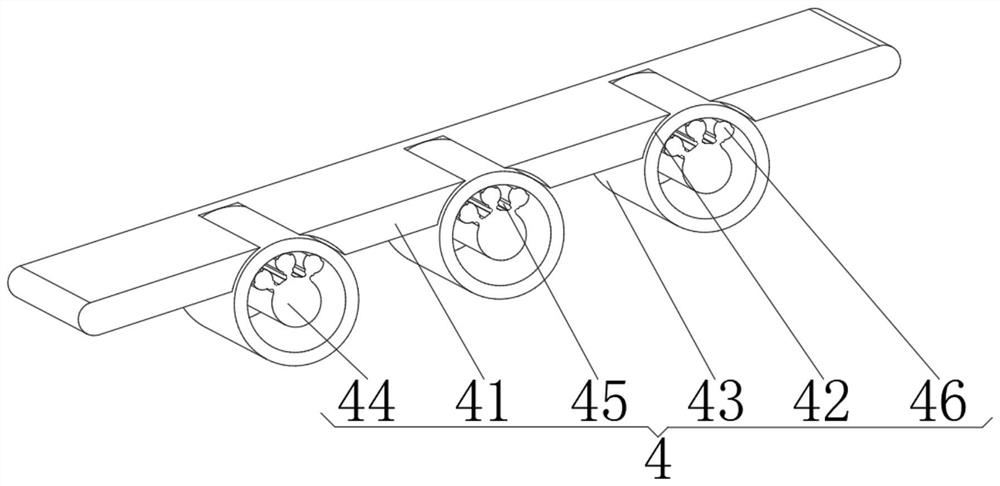

[0043]The fabric panel 41, the fabric panel 41 has a strip-shaped plate body, and a through hole 42 provided at the bottom of the strip-shaped plate body, and the abutment cylinder 43 arranged in the inner cavity of the through hole 42, and the inner cavity of the abutment cylinder 43 The positioning shaft post 44 in the middle position, the el...

Embodiment 2

[0053] see Figure 1-6 On the basis of Embodiment 1, the present invention provides a technical solution: a textile material guiding method, comprising the following steps,

[0054] Step 1: placing the textile on the fabric panel 41 and contacting with the top of the outer surface of the abutment cylinder 43;

[0055] Step 2: Continuously drag the textile along the fabric plate 41, so that it moves along the fabric plate 41, and use the friction force to rotate the abutment wheel 43;

[0056] Step 3: The rotation of the contact wheel 43 drives the rubber sleeve 33 and the magnetic block drum 34 to rotate, the position of the magnetic field line is changed through the rotation of the magnetic block drum 34, and the electromagnetic conversion power generation is performed by the generator coil 36, and the iron The columns 35 cooperate with each other to generate magnetic force, and at the same time, the generator coil 36 supplies electric energy to the heating plate 32 to gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com