Quick-change clamp

A technology of clamps and clamping blocks, which is applied in the direction of sleeve/socket connections, pipes/pipe joints/pipe fittings, passing components, etc., which can solve the problem of excessive extrusion deformation, seal failure, pipe body and sealing ring at the local position of the sealing ring The mutual movement of the brackets and other problems can be achieved to improve the sealing durability, ensure the lasting sealing performance and improve the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

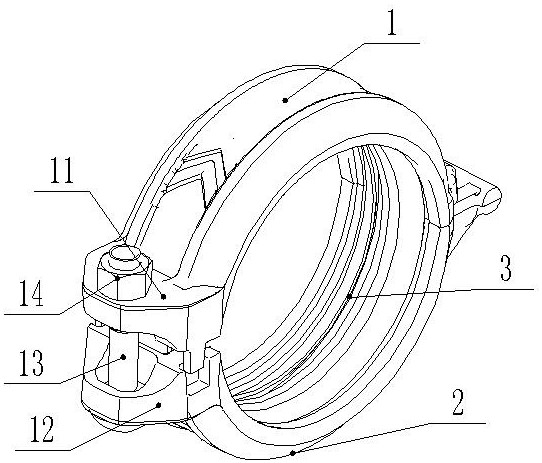

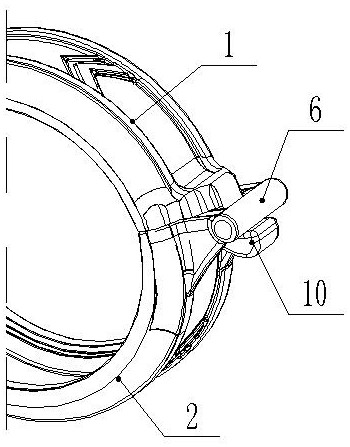

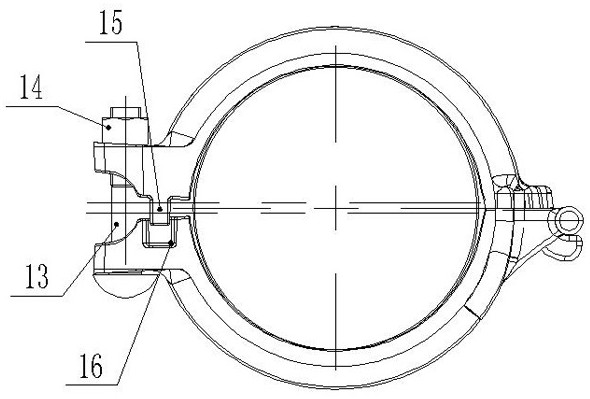

[0050] Such as Figure 1-10 Commonly shown, the present invention provides a quick-change clamp, including an upper clamping block 1 and a lower clamping block 2, the upper clamping block 1 and the lower clamping block 2 are arc rings less than a semicircle, and the upper clamping block 1 and the lower clamping block 2 are arranged oppositely to form an internal space, which is used to place the pipe body; the central axis of the internal space is collinear with the axis line of the connected pipe body; the upper clamping block 1 and the lower clamping block A gap is provided at opposite ends of the block 2 to ensure smooth insertion of the pipe into the inner space.

[0051] One end of the upper clamping block 1 and the lower clamping block 2 is connected by a screw connection structure, and the other end of the upper clamping block 1 and the lower clamping block 2 is connected by a hinged structure; For the lower clamping block 2, the opposite ends of the upper clamping blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com