A glove production drying device

A drying device and glove technology, applied in the direction of drying, drying machine, heating device, etc., can solve the problem of not being able to fix the gloves well, and achieve the effect of avoiding falling loose, shortening the time, and increasing the degree of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

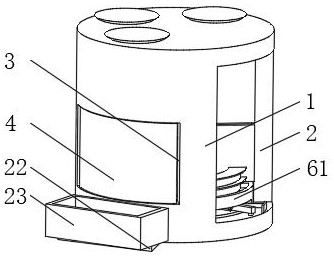

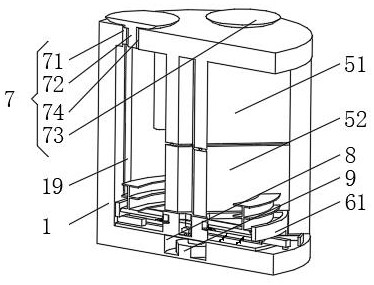

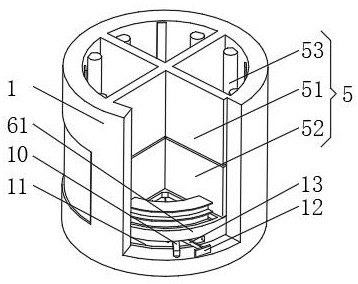

[0036] see Figure 1-6 , the present invention provides a technical solution: a drying device for glove production, comprising a drying barrel 1, a feed port 2 is opened on one side of the drying barrel 1, and a side of the drying barrel 1 is close to the feed port 2 There is a discharge port 3 at the position, and the inner top of the discharge port 3 is rotatably connected with a baffle plate 4. It is characterized in that the interior of the drying barrel 1 is provided with:

[0037] Drying device 5, the drying device 5 has a cross plate 51, the cross plate 51 is fixedly connected with the inside top of the drying barrel 1, the bottom of the cross plate 51 is symmetrically equipped with a partition plate 52, the partition plate 52 and the cross plate 51 Rotationally connected, the inner wall of the drying barrel 1 is located above the partition plate 52 and is evenly equipped with a drying lamp 53;

[0038] Stocking device 6, this stocking device 6 has stocking tray 61, an...

Embodiment 2

[0046] see Figure 1-7 , the present invention provides a technical solution: on the basis of Embodiment 1, both sides of the inner wall of the stacking chute 62 are provided with pusher troughs 14, the pusher chute 14 runs through the stacking tray 61, and the inner bottom of the pusher chute 14 Rotation is connected with seesaw 15, and the two ends of seesaw 15 all extend to the below of support plate 63, and the bottom of support plate 63 is rotatably connected with lift block 16, and lift block 16 is slidably connected with the inwall of stacker chute 62.

[0047] A buffer plate 17 is symmetrically installed on the top of the seesaw 15 , the buffer plate 17 is a thin metal sheet, and the top of the seesaw 15 is fixedly connected with a support pad 18 under the buffer plate 17 .

[0048] During use, the gloves in the stacking tray 61 rotate one circle from the feed port 2 to the discharge port 3, and the gloves to be dried are thrown onto the stacking tray 61 from the feed ...

Embodiment 3

[0050] see Figure 1-7 , the present invention provides a technical solution: on the basis of Embodiment 1, an exhaust device 7 is arranged inside the drying barrel 1, the exhaust device 7 has an exhaust hole 71, and the inside of the exhaust hole 71 is slidingly connected with Sealing column 72 , one end of sealing column 72 extending to the outside of drying barrel 1 is fixedly connected with sealing plate 73 , and the bottom end of sealing column 72 is symmetrically provided with exhaust groove 74 .

[0051] A buffer plate 17 is symmetrically installed on the top of the seesaw 15 , the buffer plate 17 is a thin metal sheet, and the top of the seesaw 15 is fixedly connected with a support pad 18 under the buffer plate 17 .

[0052] The bottom of the sealing column 72 is fixedly connected with a longitudinal plate 19, and one end of the bottom of the longitudinal plate 19 is fixedly connected with a horizontal push plate 20, and one side of the inner wall of the storage tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com