Method for online calculating number of repeated overhaul times of same fault of fan based on defect list

A technology of maintenance times and defect lists, applied in calculation, data processing applications, instruments, etc., can solve the problems of heavy analysis workload, inability to grasp the overall picture of wind farm production, and large time span, so as to achieve clear logic and improve enterprise operation. Dimensional analysis and decision-making level, and the effect of efficient operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

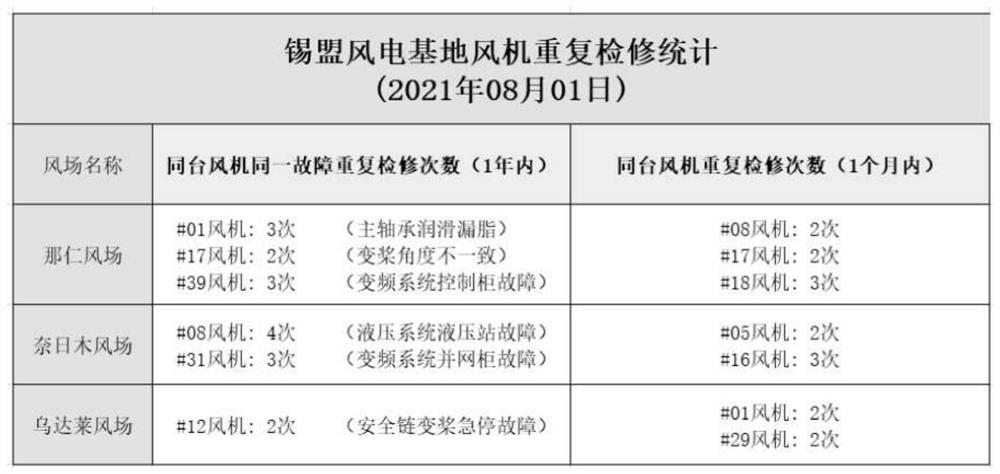

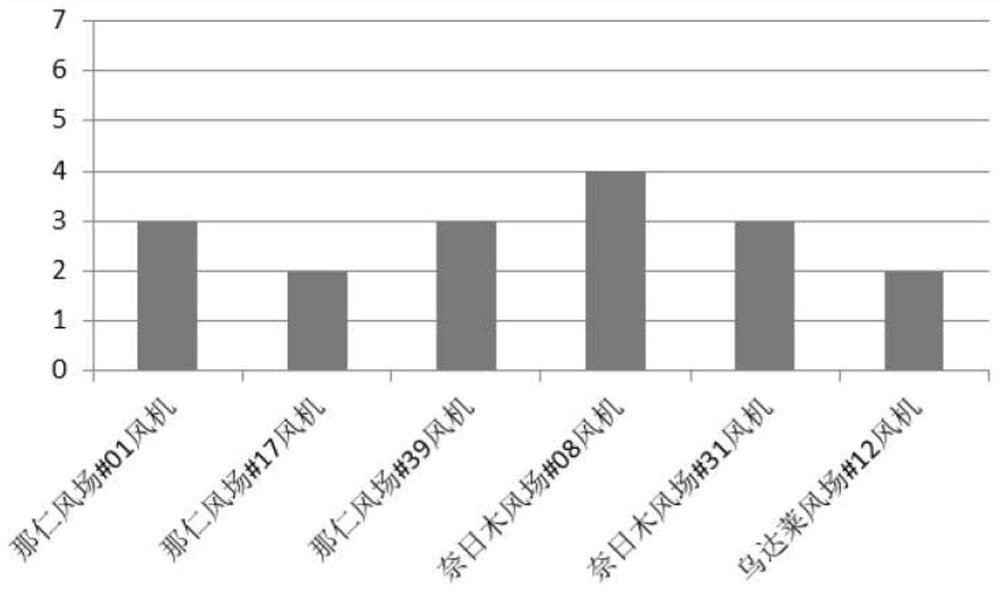

[0019] The method of the present invention to calculate the repeated maintenance times of the same fault of the wind turbine based on the defect single line has been tested on the wind power intelligent operation and maintenance project, and the automatic calculation on the intelligent operation and maintenance platform has been realized. important means of performance appraisal. Taking the headquarters of a wind power company as an example, the implementation of the method is introduced as follows:

[0020] 1) Collect and organize the field information of the three subordinate wind farm defect orders in the wind farm production management system, and extract the fields such as the state of the defect order, the ID of the defective fan, the equipment KKS, the phenomenon of the defect, and the time when the defect was created.

[0021...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com