Intelligent rapid gluing equipment for shoe production

An intelligent and fast technology, applied in the direction of footwear, application, bonding shoe parts, etc., can solve the problems of low degree of automation, small scale of gluing machine, low production rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

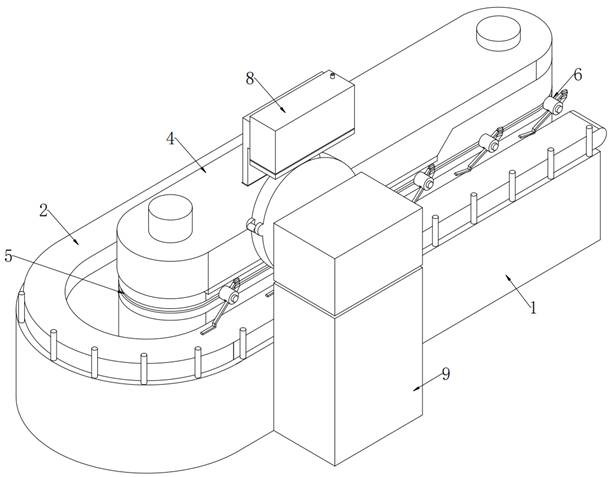

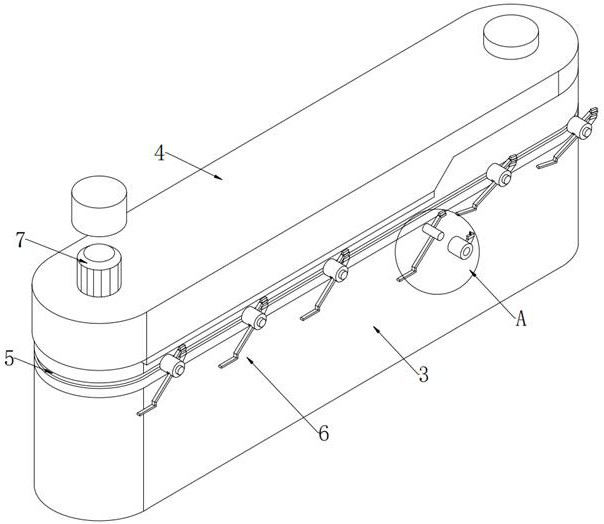

[0035] see Figure 1-9 , a kind of intelligent fast gluing equipment for shoe production, comprising a production table 1, a U-shaped feeding table 2 is installed on the production table 1, an organic box 3 is arranged inside the U-shaped feeding table 2, and an organic box 3 is fixedly installed on the top of the box 3 Cover 4, the outer wall of the cabinet 3 is provided with a loop 5 near the top, the outer wall of the cabinet 3 is equidistantly equipped with a plurality of presser foot assemblies 6, the top of the cover 4 is equipped with a first drive motor 7, and the top of the cover 4 is close to the second A driving motor 7 is equipped with a sizing material box 8, a control box 9 is installed on one side of the production table 1 and opposite to the cabinet 3, a feeding table 2 is set, and the upper spacing is placed on the table surface of the feeding table 2, which is convenient Subsequent gluing step.

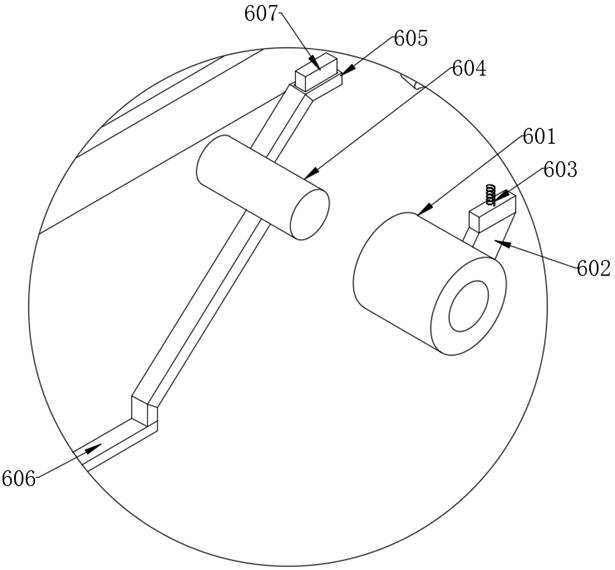

[0036] see Figure 2-3 , the presser foot assembly 6 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com