Laser long chord track smoothness detection device

A detection device and a technology of smoothness, which are applied in railway inspection vehicles, transportation and packaging, and railway vehicle shape measuring instruments, etc. Insufficient measurement accuracy, the effect of solving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

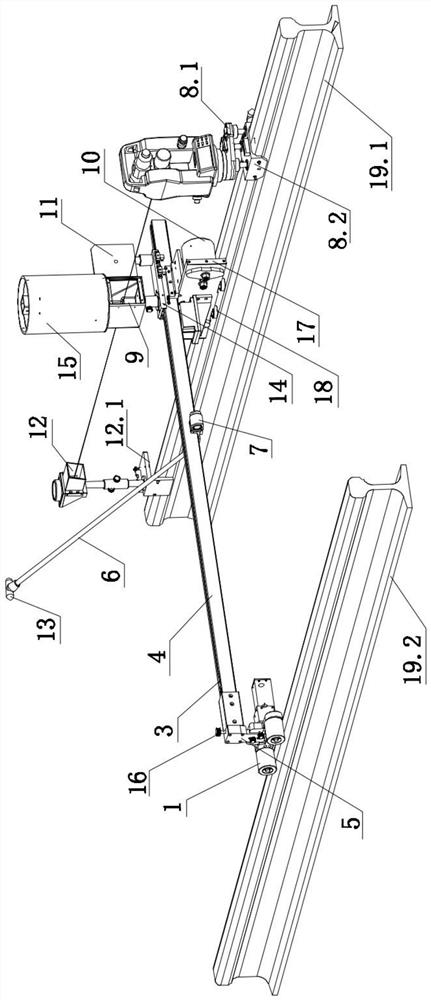

[0020] Attached below Figure 1-3 The present invention is described further:

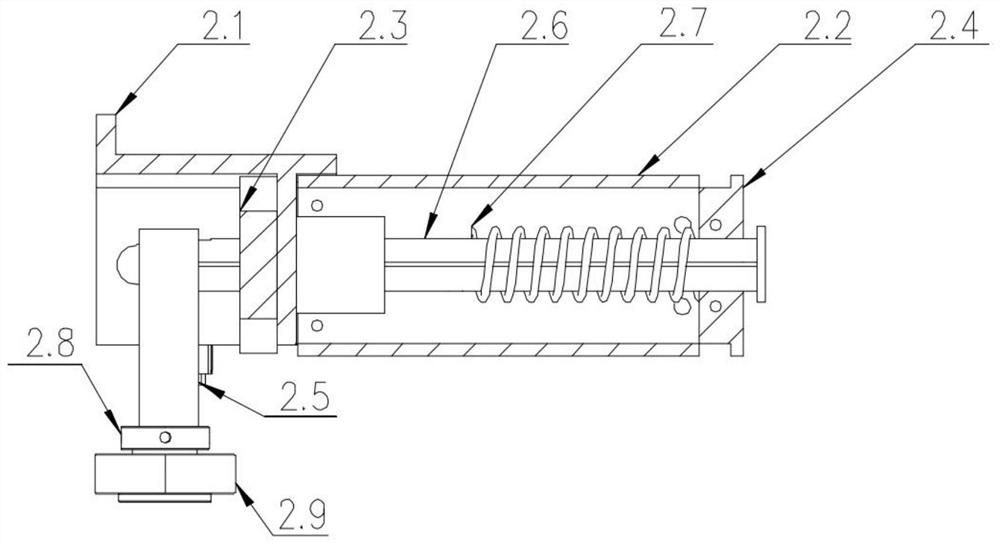

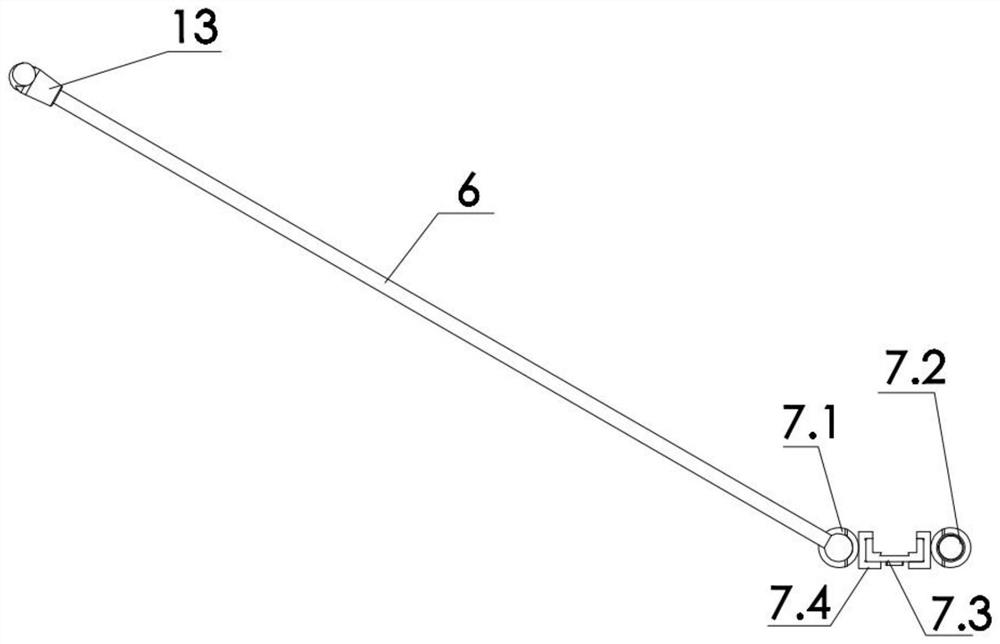

[0021] A laser long-chord track smoothness detection device, comprising a beam 4, and auxiliary wheels 1 and travel wheels 10 located at both ends of the beam 4, the beam 4 is an aluminum alloy beam, and the beam 4 is provided with a bubble-type level measuring instrument a3, The auxiliary wheel 1 is rotatably connected to the auxiliary longitudinal beam 5, one end of the crossbeam 4 is movably inserted into the auxiliary longitudinal beam 5, the adjustment wheel 16 is threadedly connected to the auxiliary longitudinal beam 5, the bottom of the adjustment wheel 16 is rotatably connected to the crossbeam 4, and the other end of the crossbeam 4 is fixed with Longitudinal beam 17 is installed, and walking wheel 10 is connected with described installation longitudinal beam 17 rotations, and installation longitudinal beam 17 bottoms are provided with horizontal detection wheel 18, and crossbeam 4 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com