Gear heat treatment device for industrial production

A technology for heat treatment devices and gears, which is applied in heat treatment furnaces, heat treatment equipment, quenching devices, etc., can solve problems such as residual impurities, damaged workpieces, and gears that are not heated to the expected effect, and achieve the effect of increased hardness and toughness, and improved work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] A gear heat treatment device for industrial production, such as Figure 1-5 As shown, it includes a support block 1, an electromagnetic heating ring 2, a push mechanism 3, a press mechanism 4 and a rotation mechanism 5. The support block 1 is provided with a push mechanism 3, and the push mechanism 3 is provided with a press mechanism 4, which is pressed down. The mechanism 4 cooperates with the pushing mechanism 3, and the upper middle part of the support block 1 is provided with a rotating mechanism 5, and the electromagnetic heating coil 2 is installed on the rotating mechanism 5.

[0077] When the gears need heat treatment, this device can be used. The worker first superimposes multiple gears on the upper front side of the support block 1, starts the operation of the pushing mechanism 3, and the pushing mechanism 3 drives the operation of the pressing mechanism 4, and the pressing mechanism 4 operates to the gear. When the push mechanism 3 drives the push-down mecha...

Embodiment 2

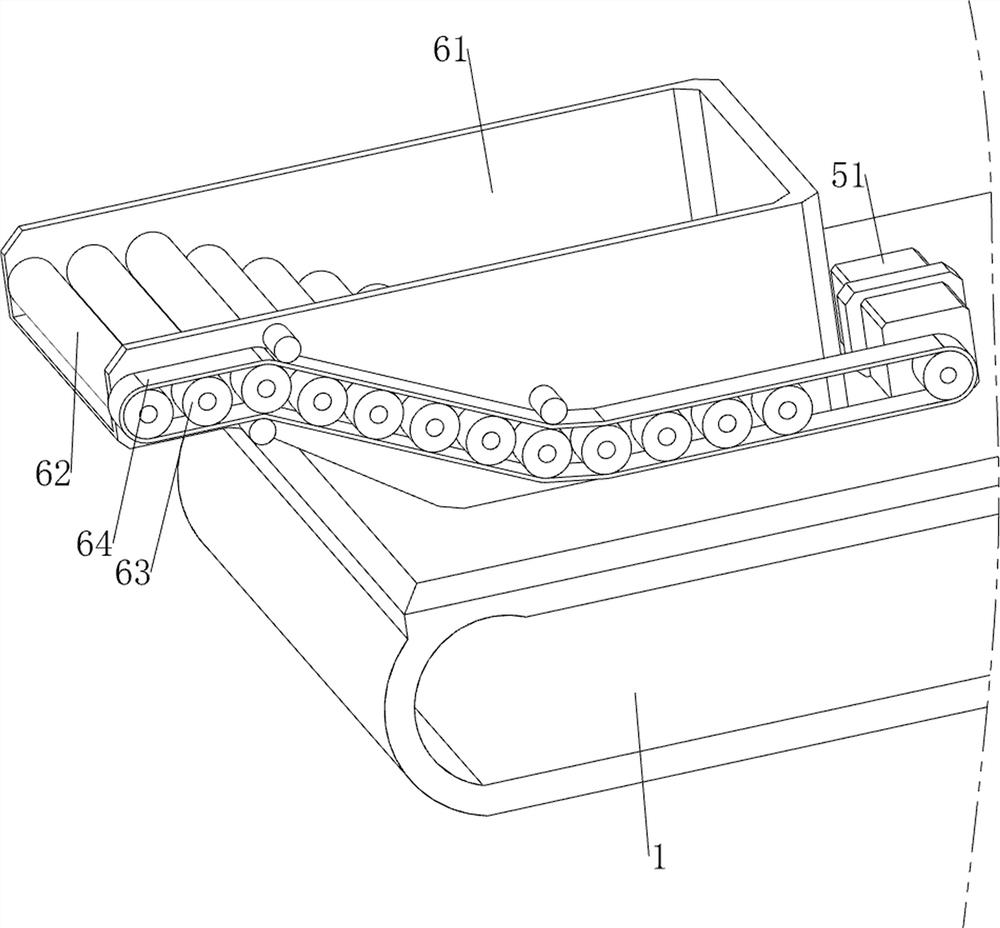

[0085] On the basis of Example 1, such as Figure 6-10 As shown, also includes transmission mechanism 6, and transmission mechanism 6 includes water tank 61, transmission roller 62, synchronous wheel 63 and synchronous belt 64, and support block 1 upper rear side is provided with water tank 61, and the rotation type on water tank 61 is provided with 12 The transmission rollers 62, the left side of the 12 transmission rollers 62 and the output shaft of the servo motor 51 are all provided with a synchronous wheel 63, and a synchronous belt 64 is connected between the 13 synchronous wheels 63.

[0086] The worker first pours an appropriate amount of water into the water tank 61. After the gear is heated, the program will control the electromagnet 45 to energize. The electromagnet 45 will pick up the gear and move backward. When the gear moves backward to the top of the water tank 61, The program will control the electromagnet 45 to be powered off, the electromagnet 45 will not ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com