Efficient zinc oxide filtering and collecting device

A high-efficiency filtration and collection device technology, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, gas treatment, etc., can solve the problems of general zinc oxide dust scouring effect and general filter cloth anti-blocking cleaning effect, etc. Excellent blocking effect and strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

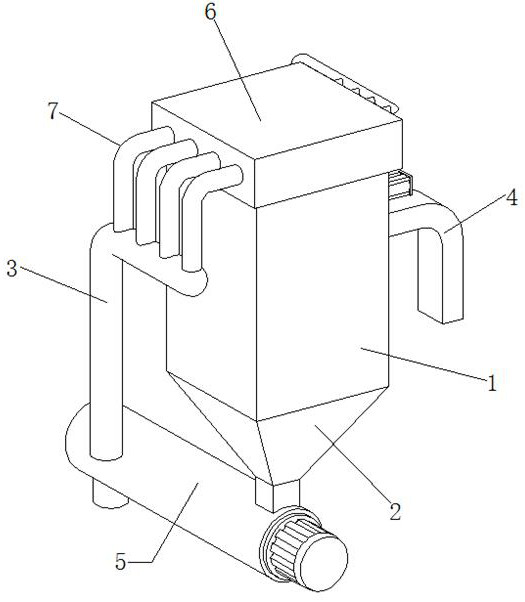

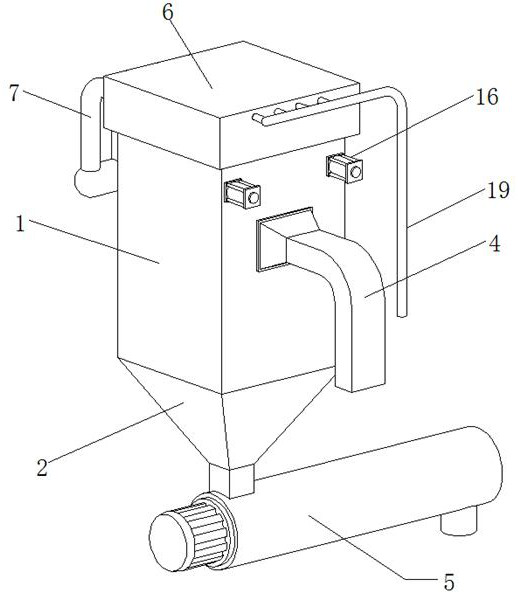

[0034] Embodiment 1 discloses a zinc oxide high-efficiency filter collection device that can effectively prevent the filter bag from clogging, please refer to the attached figure 1 And attached figure 2 , its main structure includes a collection box 1, a hopper 2, a feed pipe 3, a negative pressure air duct 4 and an auger conveyor 5. Wherein, the collecting hopper 2 is connected with the lower end of the collecting box 1, the auger conveyor 5 is connected with the lower end of the collecting hopper 2, and the negative pressure air duct 4 is connected with the right side of the collecting box 1. A splitter box 6 is connected to the upper end of the collecting hopper 2 , wherein a plurality of splitter tubes 7 arranged side by side are connected to the feed pipe 3 , and the upper ends of the plurality of splitter tubes 7 communicate with the splitter box 6 .

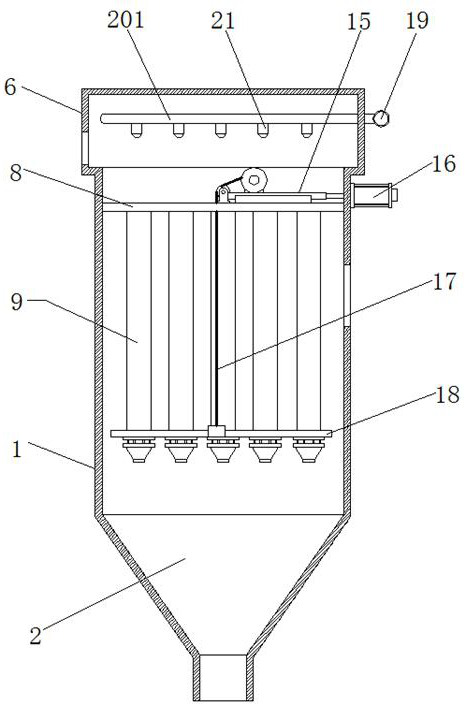

[0035] Reference attached image 3 , attached Figure 4 A partition 8 is fixedly installed on the upper end of the c...

Embodiment 2

[0042] This embodiment 2 discloses an improved zinc oxide high-efficiency filtration and collection device based on embodiment 1, and its similarities with embodiment 1 will not be described again. The difference is that this embodiment 2 is also provided with Compressed air cleaning system, wherein the compressed air cleaning system includes a compressed air source (not shown in the figure), the compressed air source is connected to the compressed air delivery main pipe 19, and the connection between the compressed air delivery main pipe 19 and the compressed air source is provided with a solenoid valve The upper end of the compressed air delivery main pipe 19 is connected with some bronchus 20 stretching into the upper end of the distribution box 6, and the lower surface of several bronchus 20 is connected with a compressed air nozzle 21 aiming at the upper opening of each filter bag assembly 9.

[0043] When the filtering effect of the filter bag assembly 9 decreases or bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com