High-stability mechanical equipment shock-resistant machine base

A mechanical equipment, high stability technology, applied in the direction of mechanical equipment, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems of insufficient shock absorption, speeding up the equipment itself and internal parts, and poor effect, so as to achieve enhanced The effect of shock absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

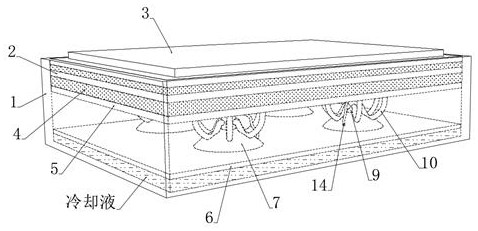

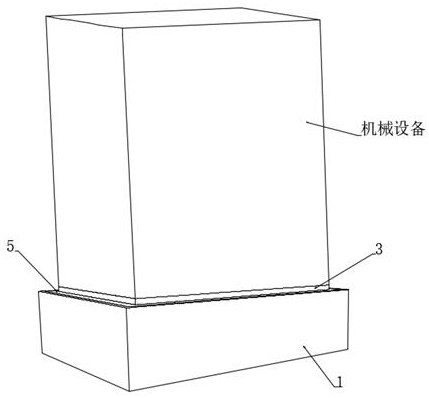

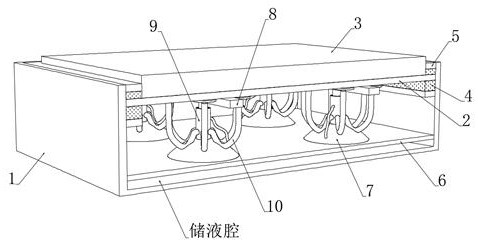

[0041] see Figure 1-2 , a highly stable anti-seismic machine base for mechanical equipment, including a shock-absorbing seat 1, the top of the shock-absorbing seat 1 is movably connected with a movable plate 2, and the upper and lower sides of the movable plate 2 are provided with limit positions fixed on the inner wall of the shock-absorbing seat 1 Gasket 5, a pair of spacer spacers 5 opposite walls are provided with buffer spacers 4, movable plate 2 is connected with a support plate 3 that runs through and extends to the outside of spacer spacers 5, a pair of buffer spacers arranged up and down The gasket 4 and the limit gasket 5 are both hollow frame structures, the support plate 3 is movably connected with the buffer gasket 4 and the limit gasket 5 located above, and the support plate 3 and the movable plate 2 form a convex structure. A pair of limit gaskets 5 set up and down play a role in limiting the movement of the movable plate 2 and the support plate 3, and the heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com