Cold-resistant and heat-resistant cold and hot dual-purpose stainless steel composite pipe

A dual-purpose, stainless steel technology, applied in the direction of protecting pipes, tubes, rigid pipes through thermal insulation, etc., can solve the problems of clogging of composite pipes, poor thermal conductivity and cold resistance of composite pipes, and burns of personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

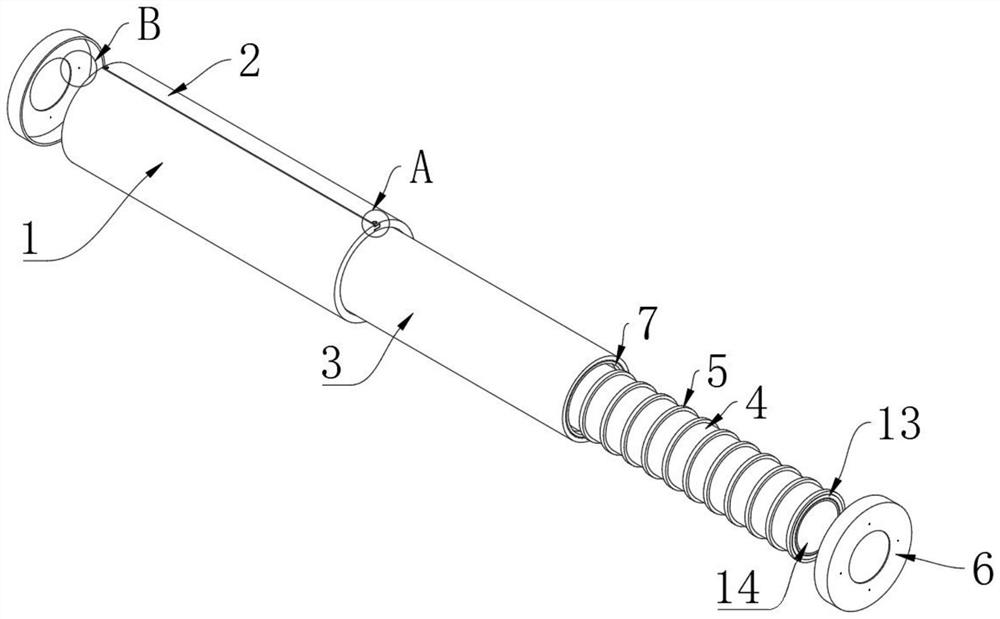

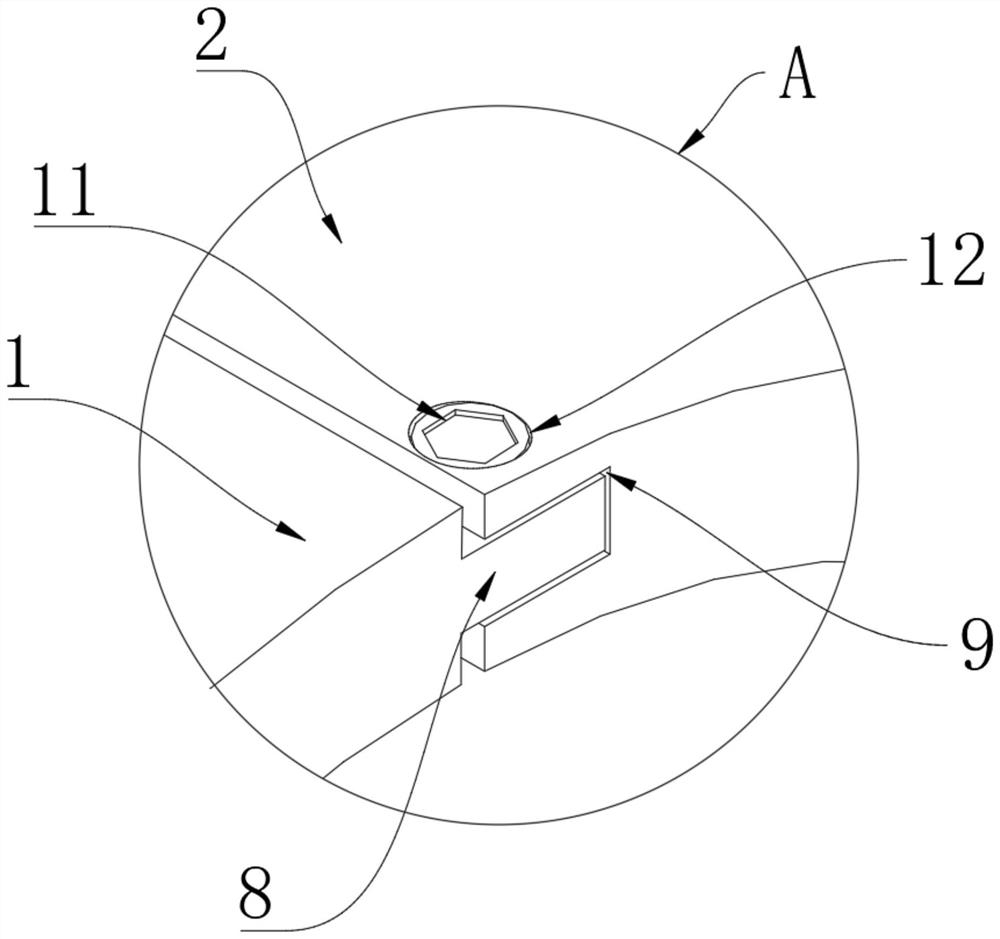

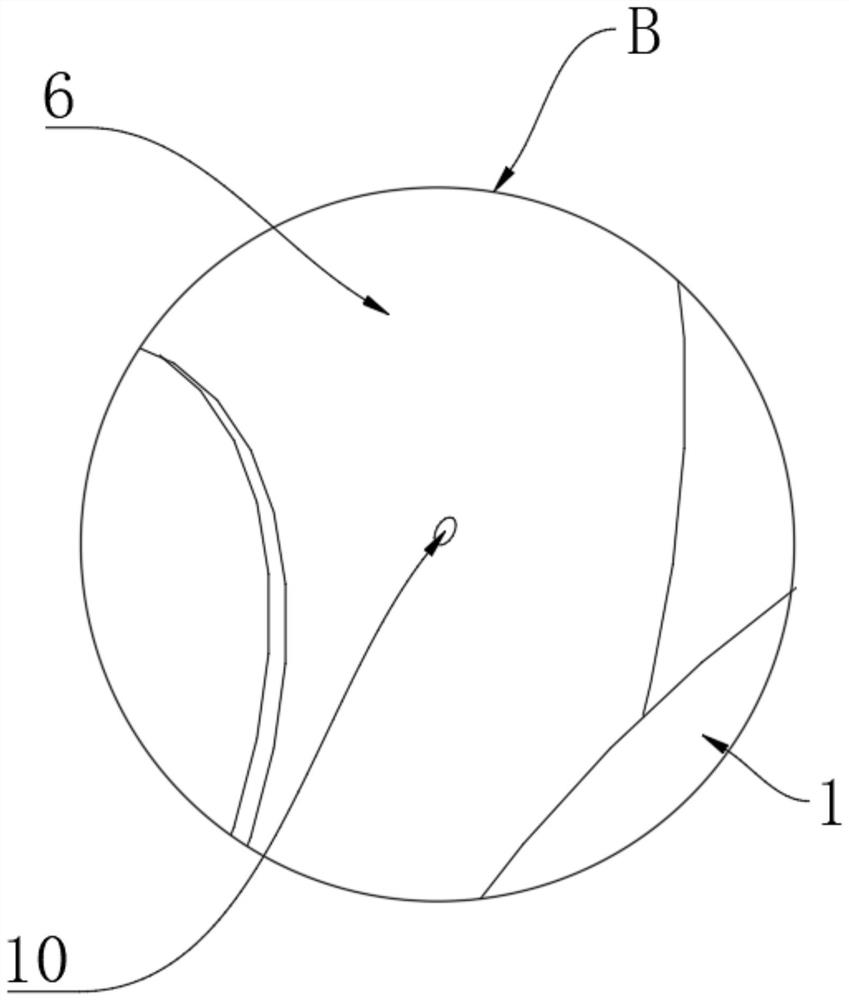

[0021] Example 1, such as Figure 1-3 As shown, a cold and heat resistant dual-purpose stainless steel composite pipe includes an inner pipe 4, the inner pipe 4 is composed of an outer stainless steel pipe layer 13 and an inner carbon steel pipe layer 14, and the outer wall of the outer pipe 7 A thermal insulation layer 3 is sleeved, a first semicircular block 2 is provided on the rear side of the outer wall of the outer tube 7, a second semicircular block 1 is provided on the front side of the outer wall of the outer tube 7, and the first semicircular block 2 is close to the second semicircular block 1 The top and the bottom of one side are all fixedly connected with clamping block 8, and the top and bottom of the second semicircular block 1 close to the first semicircular block 2 side are all provided with clamping groove 9, any one clamping block 8 and adjacent clamping groove 9 Sliding connection, the outer wall of the block 8 is provided with a sealing gasket, and the top...

Embodiment 2

[0023] Example 2, such as Figure 1-3 As shown, the outer surface of the inner tube 4 is fixedly connected with a number of evenly distributed spacer rings 5 , and the outer walls of the spacer rings 5 are sleeved with an outer tube 7 .

[0024] The effect achieved by the entire embodiment 2 is that the spacer ring 5 is evenly distributed on the outer surface of the inner tube 4 by welding, which is convenient to realize the gap between the inner tube 4 and the outer tube 7 through the role of the spacer ring 5. Furthermore, the temperature maintenance in the inner pipe 4 is realized through the heat preservation effect of the air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com