Vertical specially-shaped magnetic shielding cylinder

A magnetic shielding cylinder and magnetic shielding technology, applied in the field of magnetic shielding, can solve the problems of reduced shielding performance of the shielding room, large size of the magnetic shielding room, loss of magnetic permeability, etc., so as to improve the flexibility of use, reduce the magnetic flux leakage between the door gap, Effect of Improving Shielding Performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

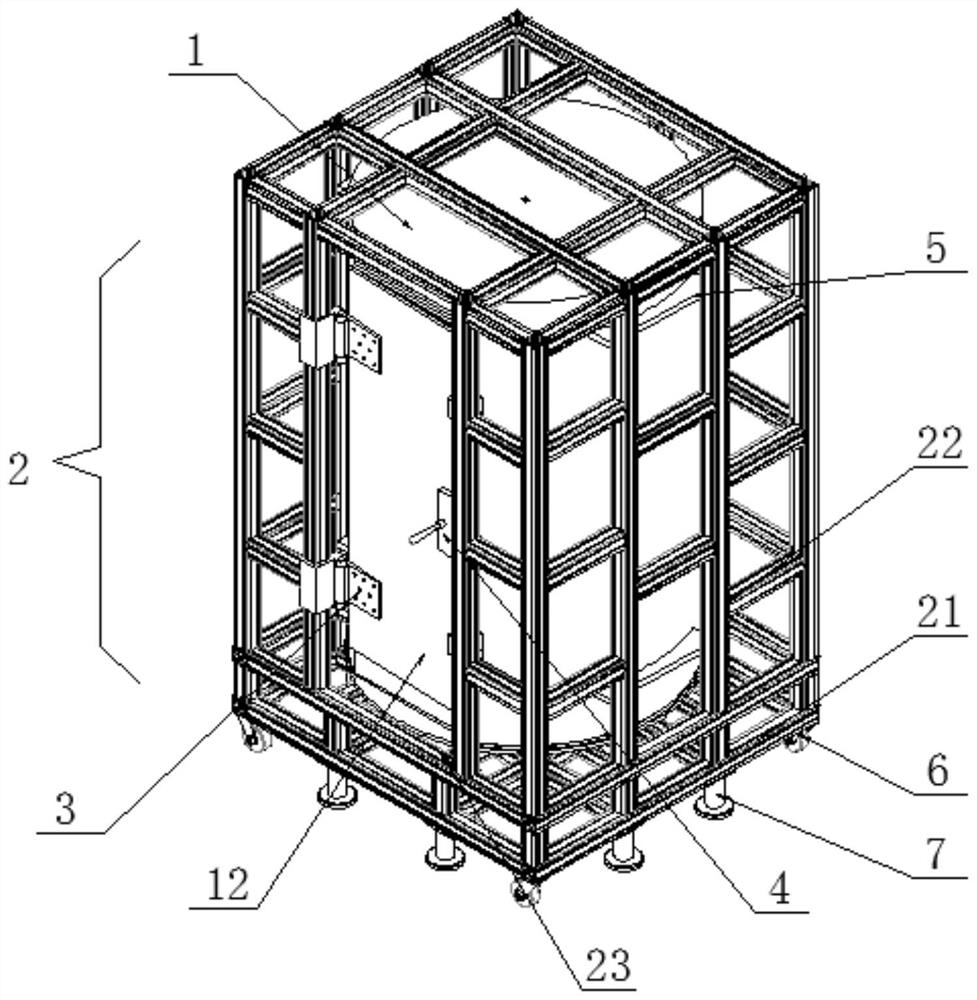

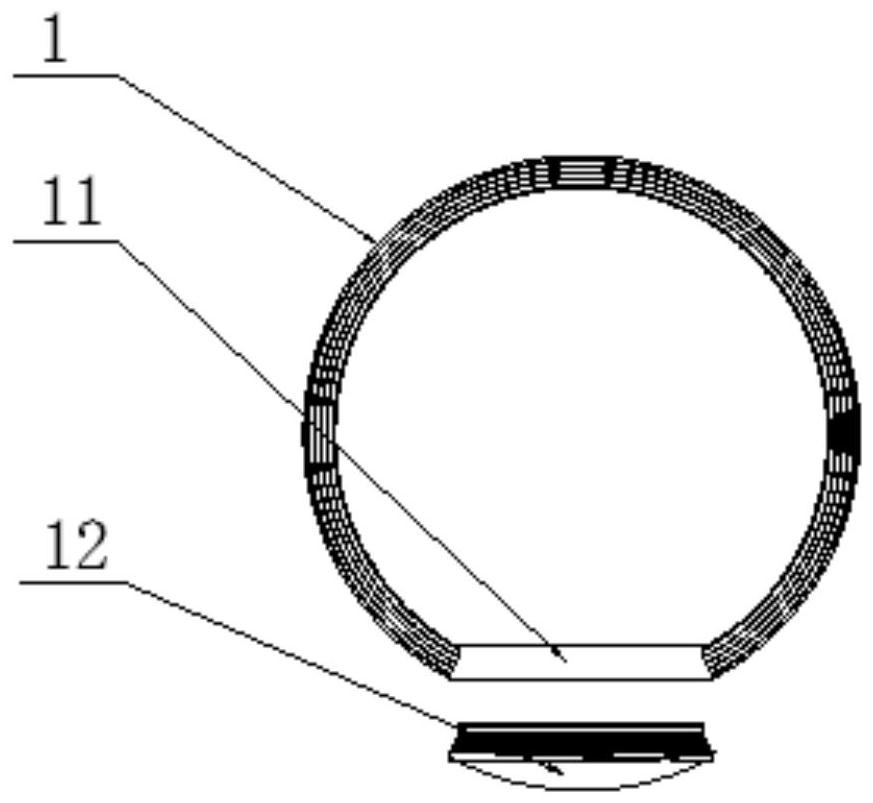

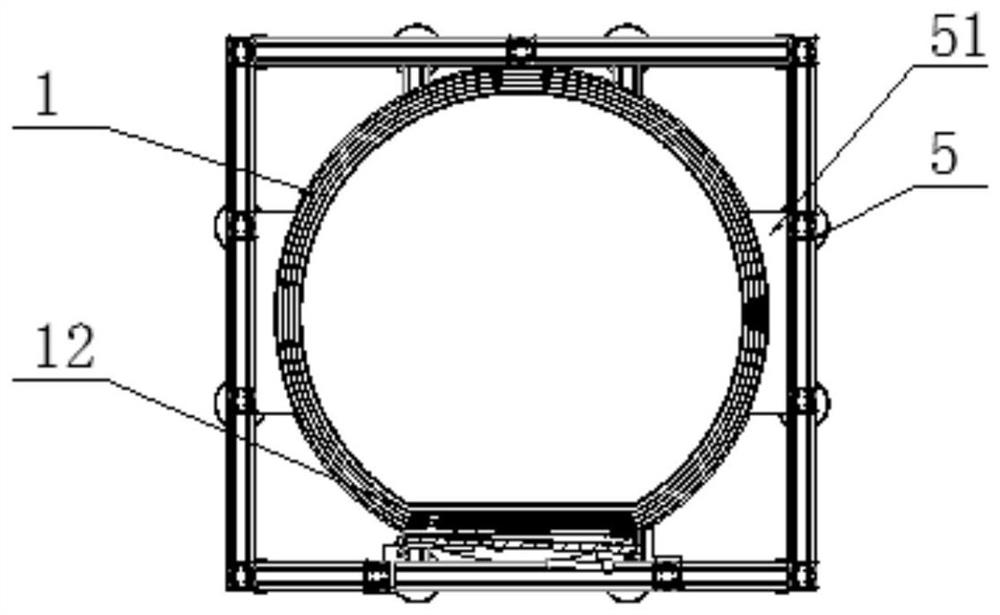

[0035] For a vertical special-shaped magnetic shielding cylinder provided in Embodiment 1 of the present invention, please refer to figure 1 and figure 2 As shown, it includes: a magnetic shielding tube 1 , a magnetic shielding door 12 and a mobile support frame 2 .

[0036] Specifically, there is a door opening 11 on the side wall of the magnetic shielding tube 1, the cross section of the magnetic shielding tube 1 is an arc structure larger than half a circle, and the cross section of the door opening 11 is a straight line structure; the magnetic shielding door 12 matches the door opening 11; The magnetic shielding cylinder 1 is vertically installed on the mobile support frame 2 .

[0037] Wherein, the mobile support frame 2 includes a base 21, the top of the base 21 is connected with a frame 22, the magnetic shielding cylinder 1 is installed on the top of the base 21, the magnetic shielding cylinder 1 is fixedly connected with the frame 22, and one side of the frame 22 is ...

Embodiment 2

[0046] For a vertical special-shaped magnetic shielding cylinder provided in Embodiment 2 of the present invention, please refer to figure 1 and figure 2 As shown, it includes: a magnetic shielding tube 1 , a magnetic shielding door 12 and a mobile support frame 2 .

[0047] Specifically, there is a door opening 11 on the side wall of the magnetic shielding tube 1, the cross section of the magnetic shielding tube 1 is an arc structure larger than half a circle, and the cross section of the door opening 11 is a straight line structure; the magnetic shielding door 12 matches the door opening 11; The magnetic shielding cylinder 1 is vertically installed on the mobile support frame 2 .

[0048] Wherein, the mobile support frame 2 includes a base 21, the top of the base 21 is connected with a frame 22, the magnetic shielding cylinder 1 is installed on the top of the base 21, the magnetic shielding cylinder 1 is fixedly connected with the frame 22, and one side of the frame 22 is ...

Embodiment 3

[0057] For a vertical special-shaped magnetic shielding cylinder provided in Embodiment 3 of the present invention, please refer to figure 1 and figure 2 As shown, it includes: a magnetic shielding tube 1 , a magnetic shielding door 12 and a mobile support frame 2 .

[0058] Specifically, there is a door opening 11 on the side wall of the magnetic shielding cylinder 1, which can accommodate at least one adult to enter and exit normally; the magnetic shielding door 12 matches the door opening 11;

[0059] Wherein, the mobile support frame 2 includes a base 21, the top of the base 21 is connected with a frame 22, the magnetic shielding cylinder 1 is installed on the top of the base 21, the magnetic shielding cylinder 1 is fixedly connected with the frame 22, and one side of the frame 22 is provided with a magnetic shielding door 12 for opening. The opening 23 . At least one caster 6 is provided at the four corners of the bottom of the base 21 respectively. An anchor 7 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com