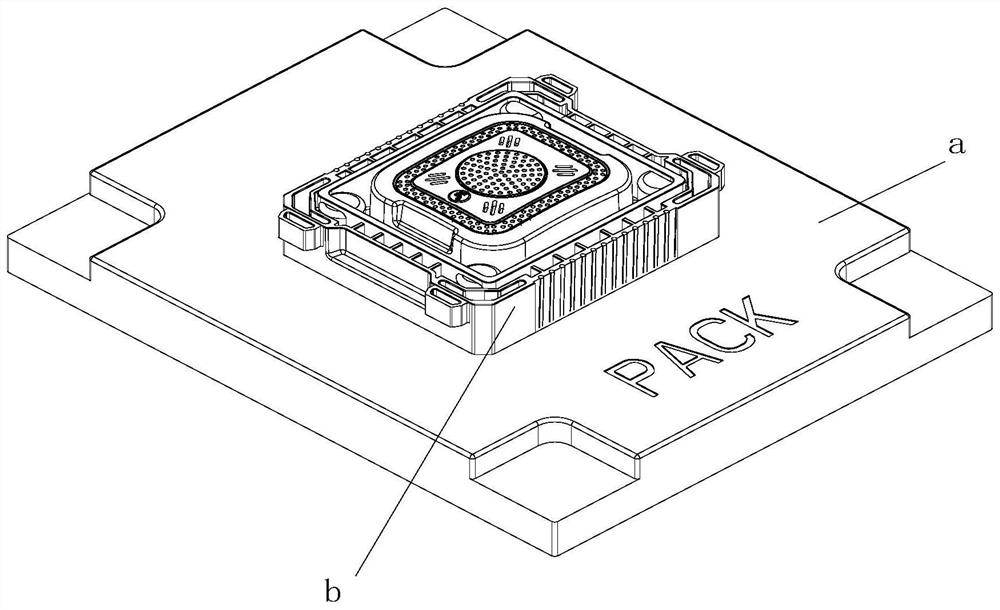

Explosion-proof valve sealing device for air tightness test of lithium battery box body

An air-tightness testing and sealing device technology, which is used in fluid-tightness testing, measuring devices, and liquid-tightness measurement using liquid/vacuum degree. and other problems, to achieve the effect of improving the pressure bearing capacity and test efficiency, which is conducive to a large number of popularization and use, and has a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

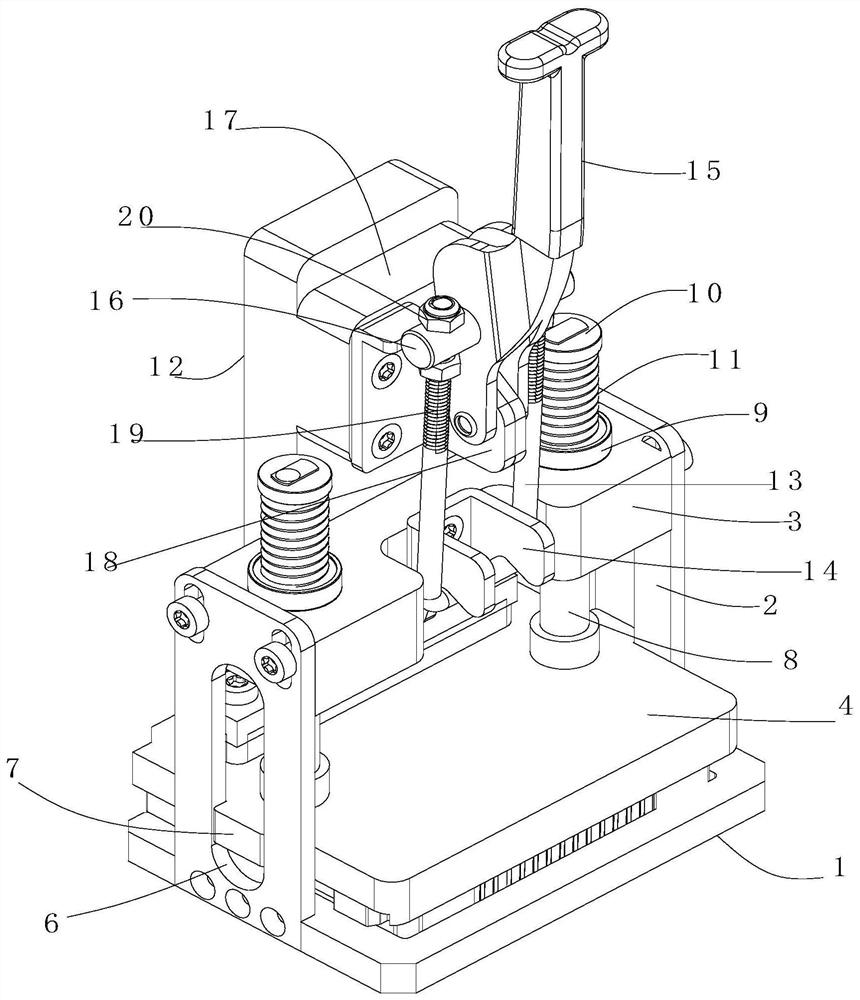

[0019] refer to Figure 2-Figure 5 , the present invention proposes an explosion-proof valve sealing device for air tightness testing of a lithium battery box, including a support member and a seal member; wherein:

[0020] The support member includes a support card seat 1, the support card seat 1 is a U-shaped structure, and an explosion-proof valve slot is formed in it, and two support plates 2 are fixed on the support card seat 1, which are located on both sides of the explosion-proof valve slot and arranged oppositely. A waist-shaped chute 6 arranged vertically is opened on the support plate 2 .

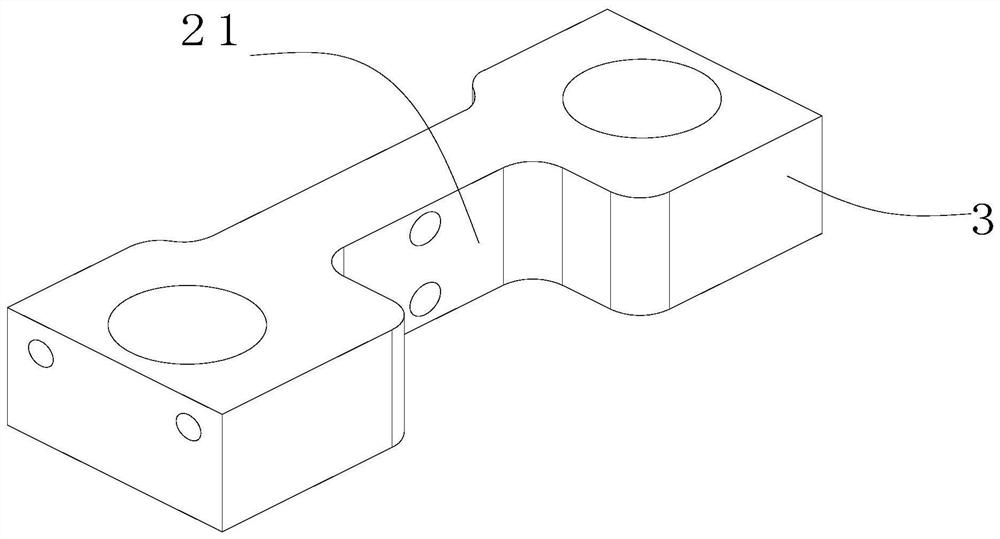

[0021] The seal includes a fixed plate 3 and a sealing plate 4 . The fixing plate 3 is located above the supporting bracket 1 and its two ends are respectively fixedly connected with the two supporting plates 2 by bolts. The sealing plate 4 is located between the supporting deck 1 and the fixed plate 3 and is parallel to the supporting deck 1. Both sides of the sealing plate 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com