Reaction wheel configuration optimization method and system considering fault condition

A reaction wheel and configuration optimization technology, applied in the field of aerospace control, can solve problems such as difficulty in effectively improving the control capability of the reaction wheel, lack of systematic configuration methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

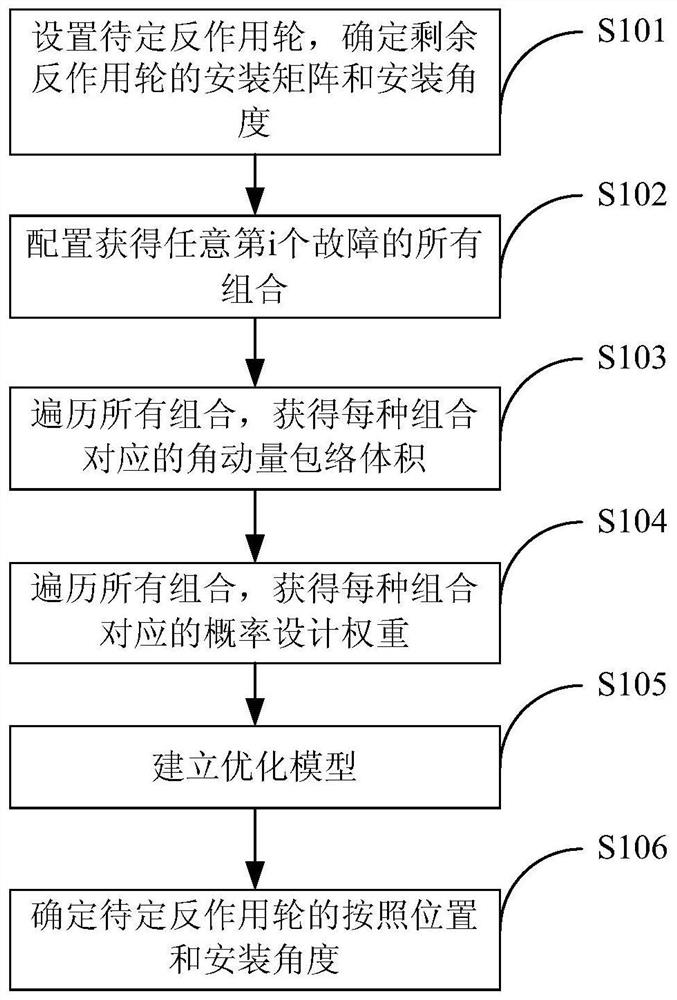

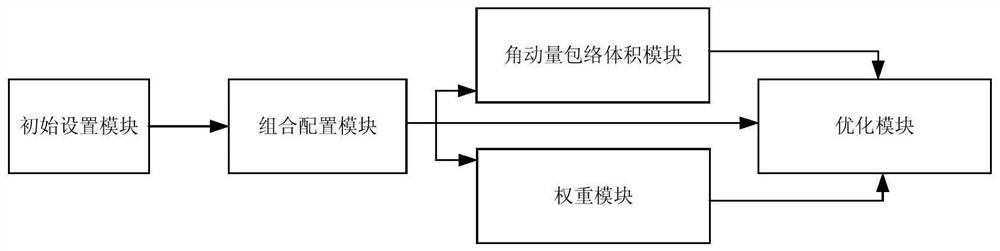

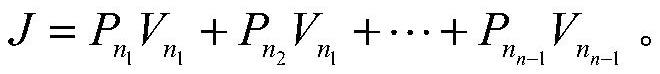

[0047] A reaction wheel configuration optimization method considering fault conditions. For a control system with n reaction wheels, the first step is to randomly select one reaction wheel from the n reaction wheels as the undetermined reaction wheel, and determine the installation matrix and installation angle of the remaining n-1 reaction wheels; the second step , obtain all the combinations that make any i-th reaction wheel out of the n-1 reaction wheels described in step 1 fail, and the remaining n-2 reaction wheels and undetermined reaction wheels work normally, and traverse all combinations to calculate the reaction wheel except the fault The angular momentum envelope volume V enclosed by all the reaction wheels outside ni ; The third step is to traverse and calculate the probability design weight P of the remaining n-2 reaction wheels when any i-th reaction wheel fails in the n-1 reaction wheels ni ; The fourth step, according to the angular momentum envelope volume V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com