Reverse-switching switch cabinet

A technology of switch cabinets and switches, which is applied in substation/switch layout details, busbar/line layout, substation/power distribution device shell, etc., can solve problems such as inconvenient construction, large volume, and less alarm information/prompt information, etc., to achieve Ease of troubleshooting, space saving, low impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

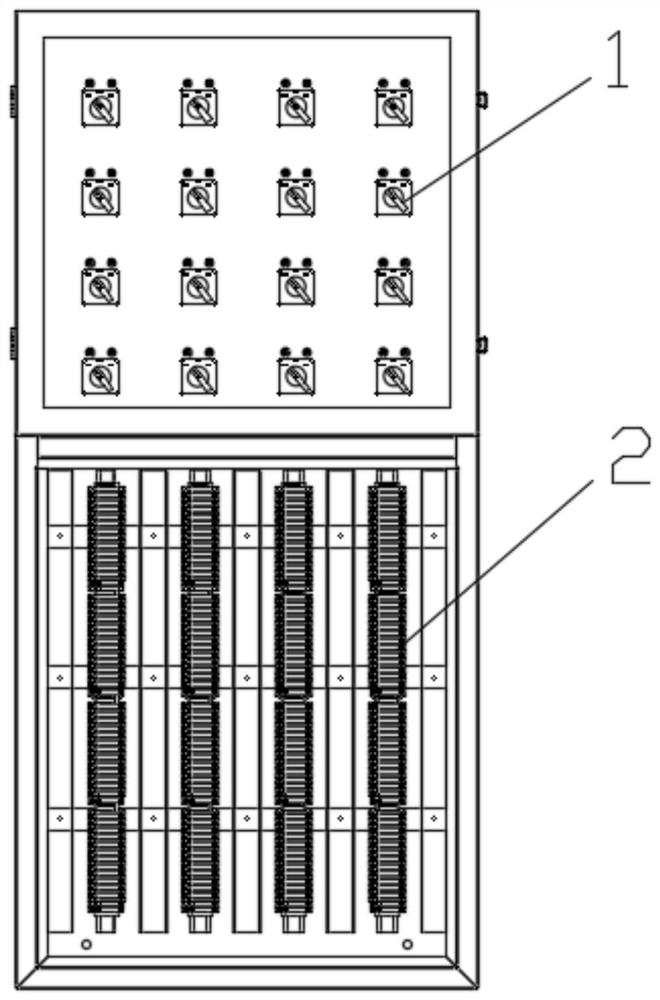

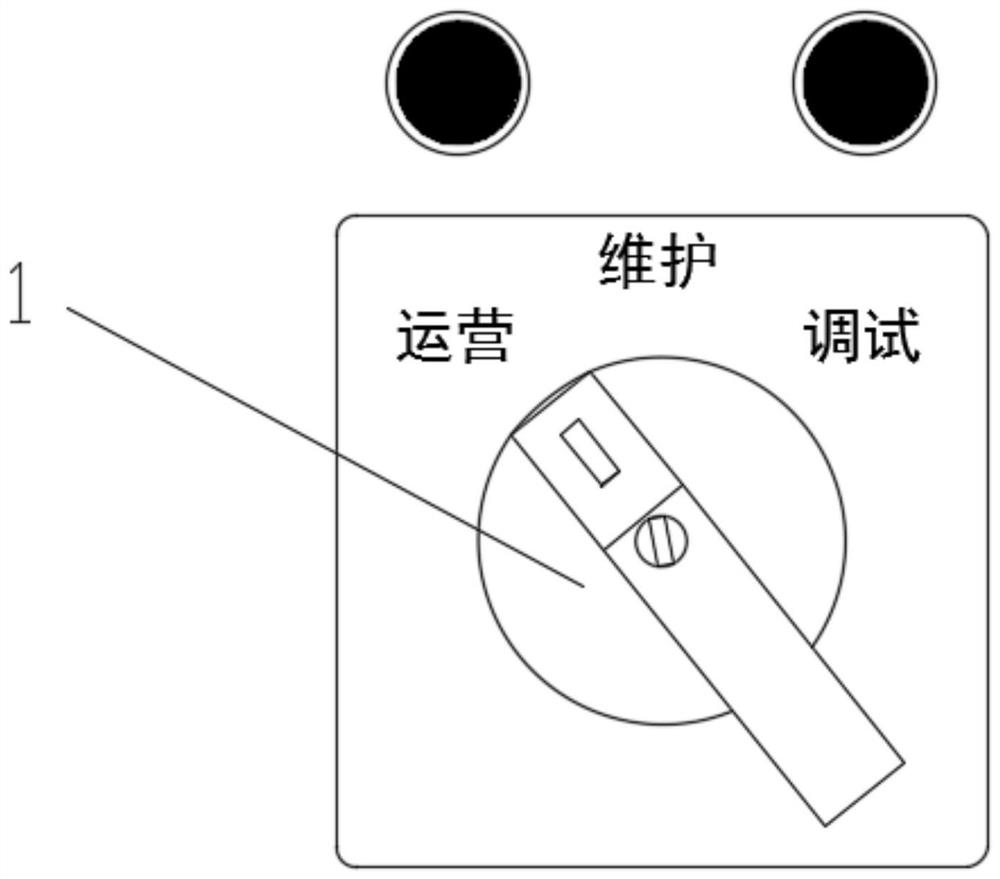

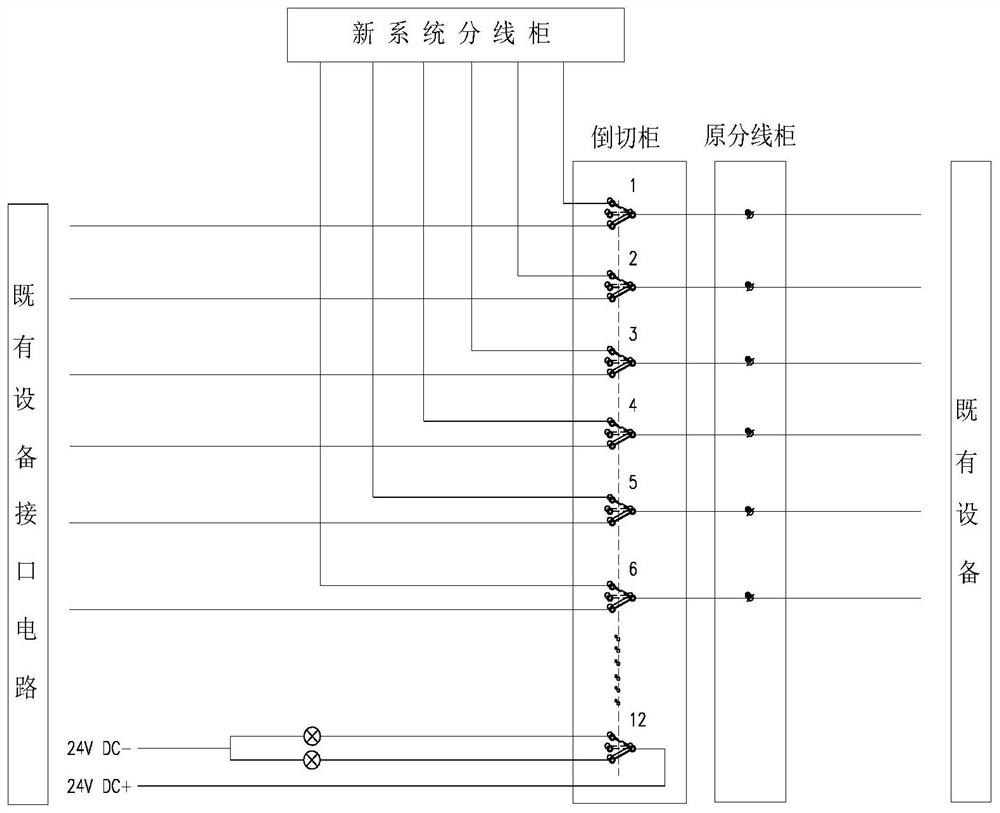

[0024] see Figure 1-4 , the downcutting switchgear of the present invention comprises an upper cabinet body and a lower cabinet body, a plurality of downcutting switches 1 are installed in an array on the front of the upper cabinet body, and a plurality of downcutting switches 1 are installed on the front side of the lower cabinet body, respectively electrically connected to each downcutting switch 1 A wiring terminal 2. The cabinet door of the upper cabinet body is a glass door, and two locks are installed on the glass door. The operation and wiring of the cabinet are all done on the front, no rear maintenance is required, and the size of the cabinet is small, so it can be installed against the wall or in a corner. It can well solve the problem that there is no extra space in the existing equipment room to install large-size cabinets. Since the operation and wiring are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com