A dust-proof and heat-dissipating permanent magnet motor

A permanent magnet motor, heat dissipation technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of lack of heat dissipation device, affecting user efficiency, damage, etc., to improve placement stability and reduce damage. Probability, effect of improving service life and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

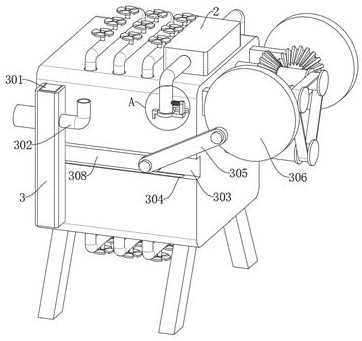

[0036] see Figure 1-7 , the present invention provides the following technical solutions:

[0037] A dust-proof and heat-dissipating permanent magnet motor, comprising:

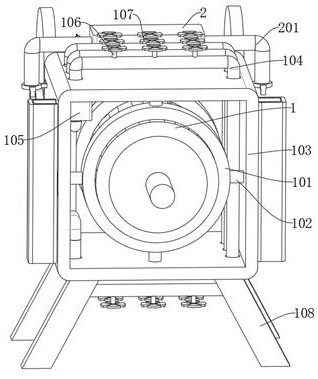

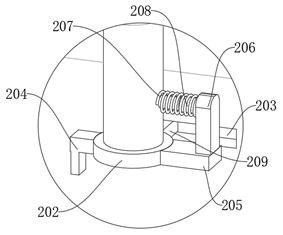

[0038] One end is a load-bearing heat-conducting shell 103 with an opening, and a permanent-magnet double-axis motor 1 is arranged inside the load-bearing heat-conducting shell 103. Two heat-collecting rings 101 are fixedly connected to the circumferential surface of the permanent-magnet double-axis motor 1, and the circumference of the two heat-collecting rings 101 The surface is fixedly connected with a plurality of heat conduction pipes 102, and the plurality of heat conduction pipes 102 are fixedly connected with the inner surface of the heat conduction shell 103;

[0039] A plurality of heat dissipation holes, a plurality of heat dissipation holes are opened at the upper and lower ends of the heat conducting shell 103 respectively, a cooling pipe 104 is fixedly connected in the plurality of heat dissip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com