A multi-tube solid-liquid separation filter device

A solid-liquid separation and filtration device technology, applied in separation methods, filtration separation, moving filter element filters, etc., can solve the problems of lower solid-liquid mixture separation efficiency, lower solid-liquid separation rate, mutual pollution, etc., and achieve improved purity. degree, improve efficiency, and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

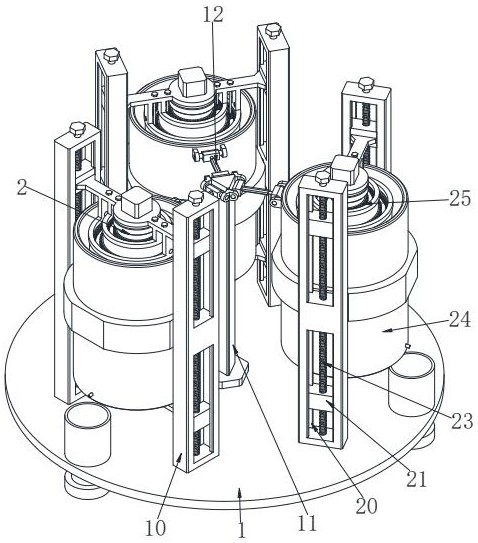

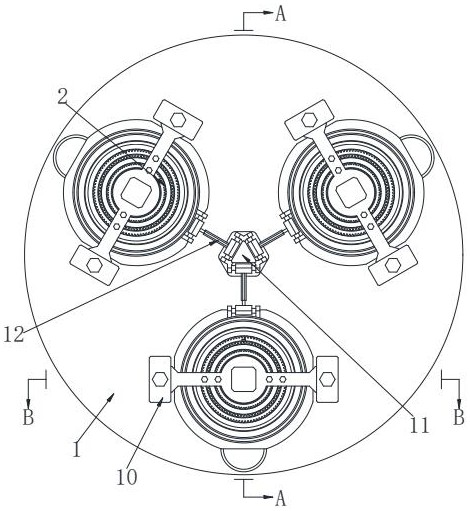

[0028] refer to figure 1 , a multi-tubular solid-liquid separation filtration device, comprising a base 1 and a separation unit 2, the base 1 is provided with the separation unit 2.

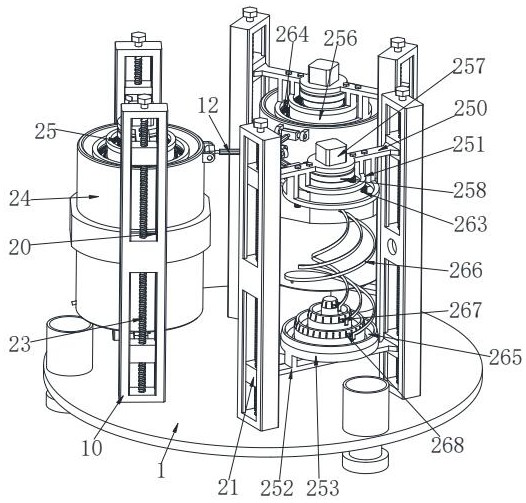

[0029] refer to figure 1 and figure 2 The edge of the upper surface of the base 1 is evenly provided with several pairs of vertical auxiliary struts 10 along its circumferential direction, the middle part between each pair of auxiliary struts 10 is provided with a separation unit 2, and the center of the upper surface of the base 1 is provided with a An auxiliary vertical rod 11 , an electric push rod 12 is jointly hinged between the upper end of the auxiliary vertical rod 11 and the separation unit 2 .

[0030] refer to Figure 1 to Figure 5 , the separation unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com