Interior and exterior wall high-silicon putty powder proportioning device and preparation method thereof

A technology for putty powder and internal and external walls, applied in the field of putty powder, can solve the problems affecting the quality of high-silicon putty powder for internal and external walls, affecting the full mixing of various raw materials, affecting the proportion of various raw materials, etc., so as to improve the screening effect and reduce the quality. , to avoid the effect of breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

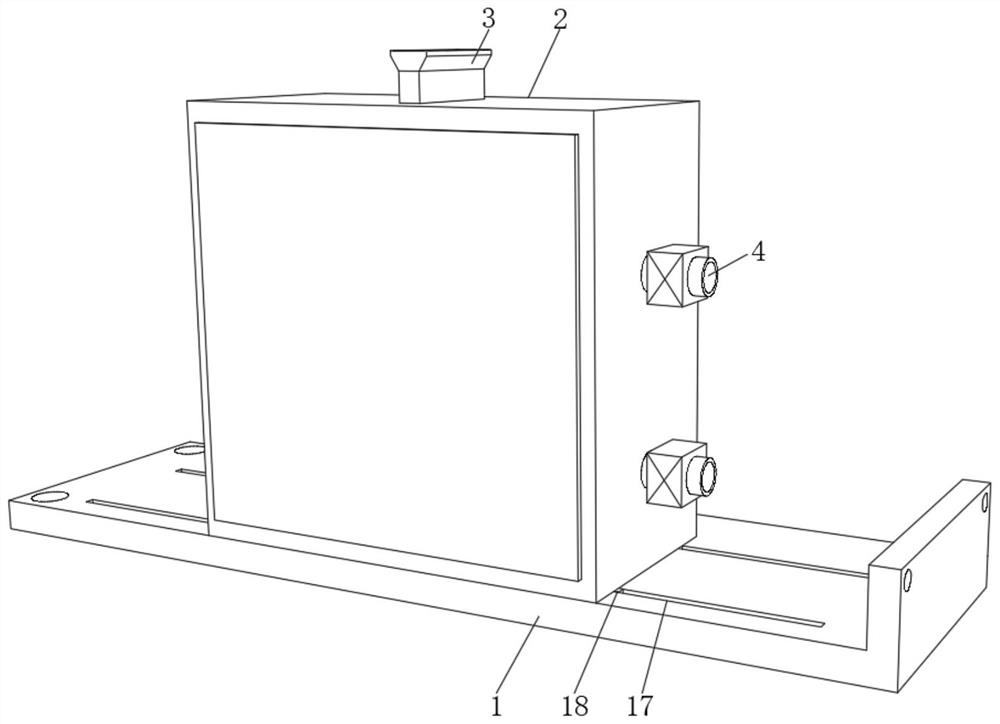

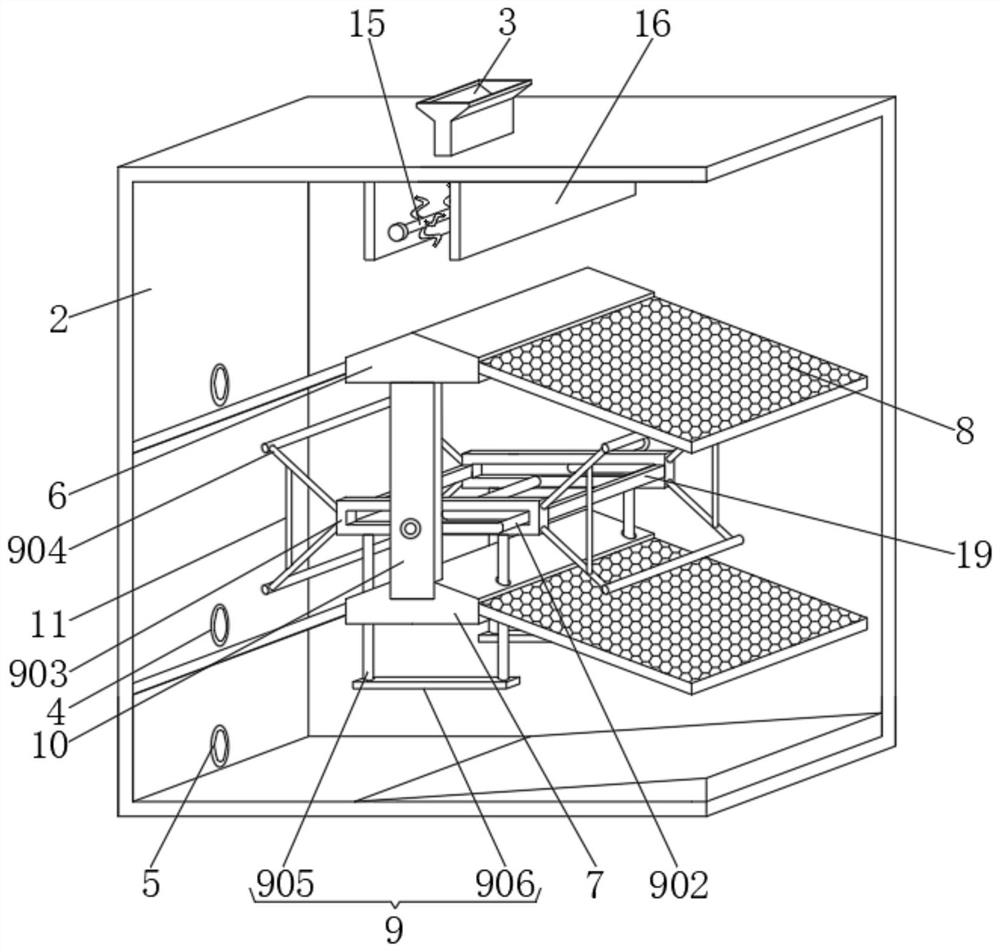

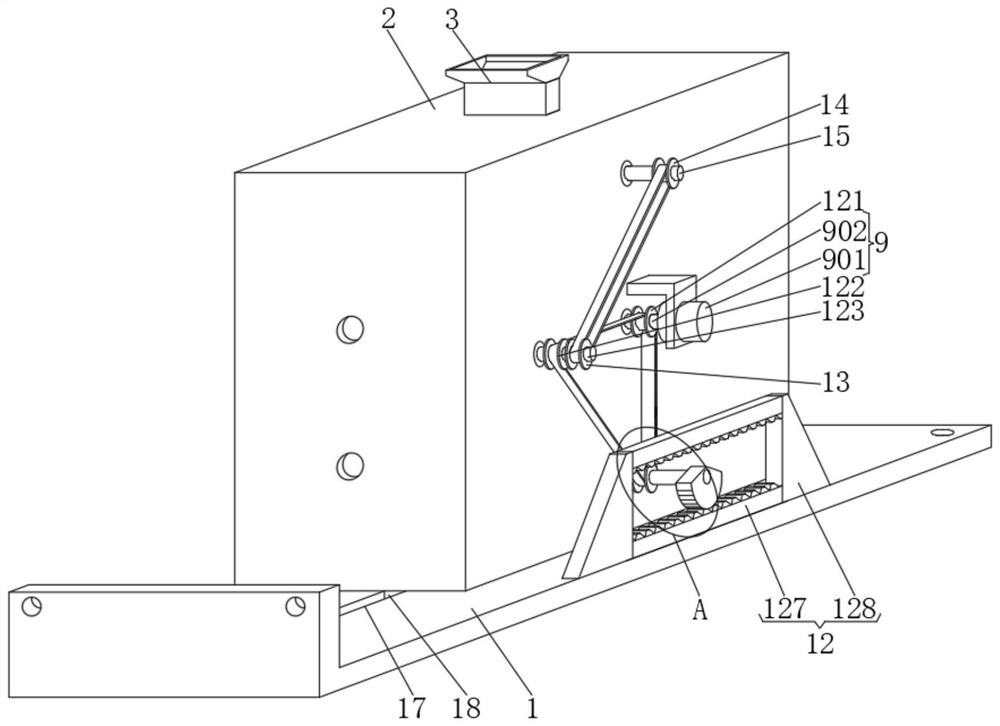

[0039] Attached to the following Figure 1-7 The present invention will be described in further detail.

[0040]The high-silicon putty powder proportioning device for interior and exterior walls includes a base 1 on which a box 2 is slidably arranged, the top of the base 1 is provided with sliding grooves 17 along the front and rear directions, and the front and back of the bottom of the box 2 are fixedly connected with Sliding plate 18, the surface of the sliding plate 18 is slidingly connected with the inner chamber of the sliding groove 17, the sliding plate 18 is a convex structure, and the cooperative use of the sliding groove 17 and the sliding plate 18 facilitates the unimpeded left and right displacement of the auxiliary box body 2, while preventing the box body 2 When moving away from the base 1, the box body 2 is damaged, which prolongs the service life of the box body 2. The top of the box body 2 is connected with the feed trough 3, and the inner cavity of the box b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com