An automatic bending device for alloy aluminum

A technology of bending device and alloy aluminum, which is applied in the field of metal processing, can solve the problems that the pipe does not adapt to the bending device, the rebound and reset of the pipe, etc., and achieves the effect of simple structure and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

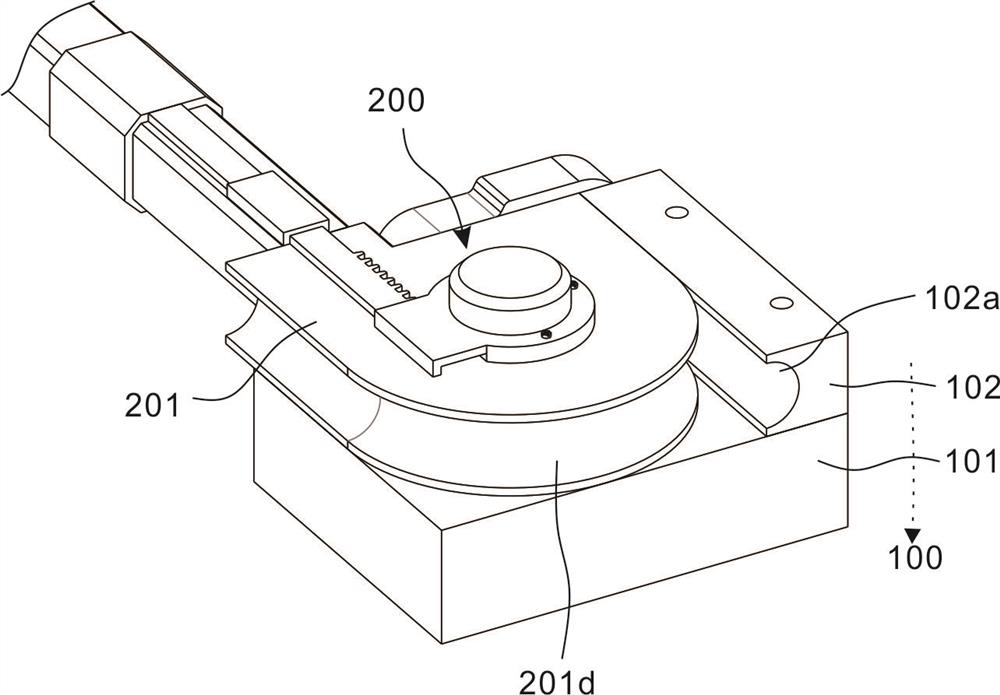

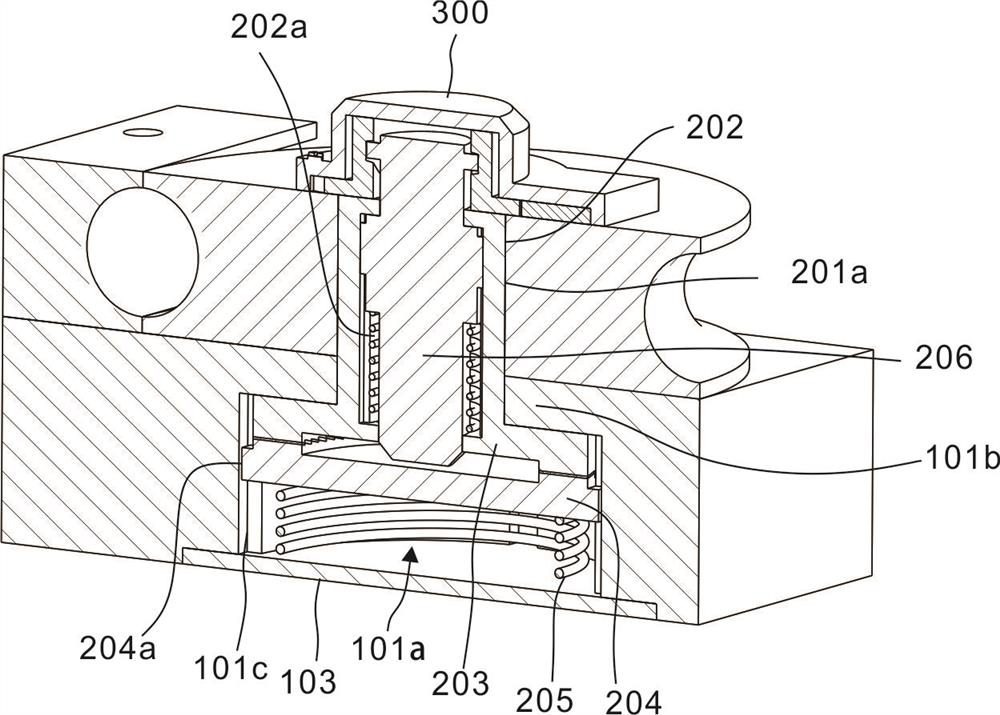

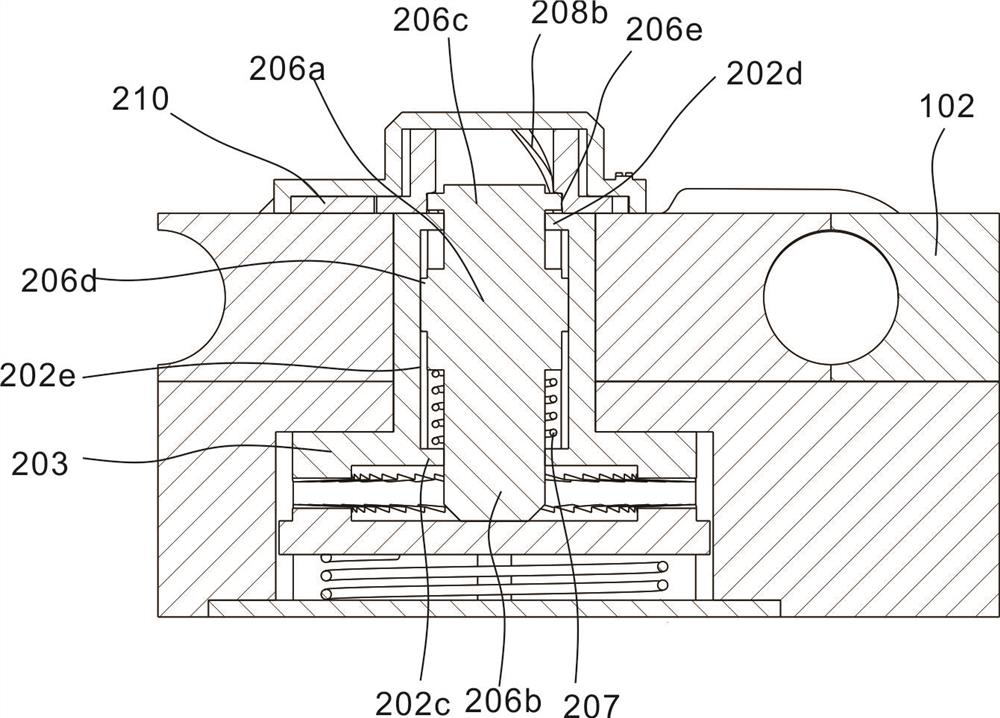

[0031] Example: refer to Figure 1~5 , this embodiment provides an alloy aluminum automatic bending device, including a fixing assembly 100 and a bending assembly 200, wherein the fixing assembly 100 includes a base 101, a guide seat 102 fixedly connected with the base 101, and the base 101 is used for fixing and supporting The bending assembly 200, the guide seat 102 is used to guide the unbent aluminum alloy pipe; the base 101 is provided with a first hole 101a; The hole 101a rotates at the center of a circle, wherein the arc-shaped side of the rotating disk 201 is tangent to the side of the guide seat 102, and the pipe to be bent can pass between the rotating disk 201 and the guide seat 102.

[0032] Further, the rotating disk 201 is provided with a through hole 201a, and the through hole 201a is connected with a fixed shaft 202, and the fixed shaft 202 is fixedly connected with the through hole 201a, which can be connected by welding or bolts; the fixed shaft 202 extends i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com