Rail transit sanding system

A technology for rail transit and crushing sand, applied in the field of rail transit, can solve the problems of inability to sprinkle sand and crush, and achieve the effects of avoiding wet agglomeration, improving friction coefficient, and avoiding sand spreading and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

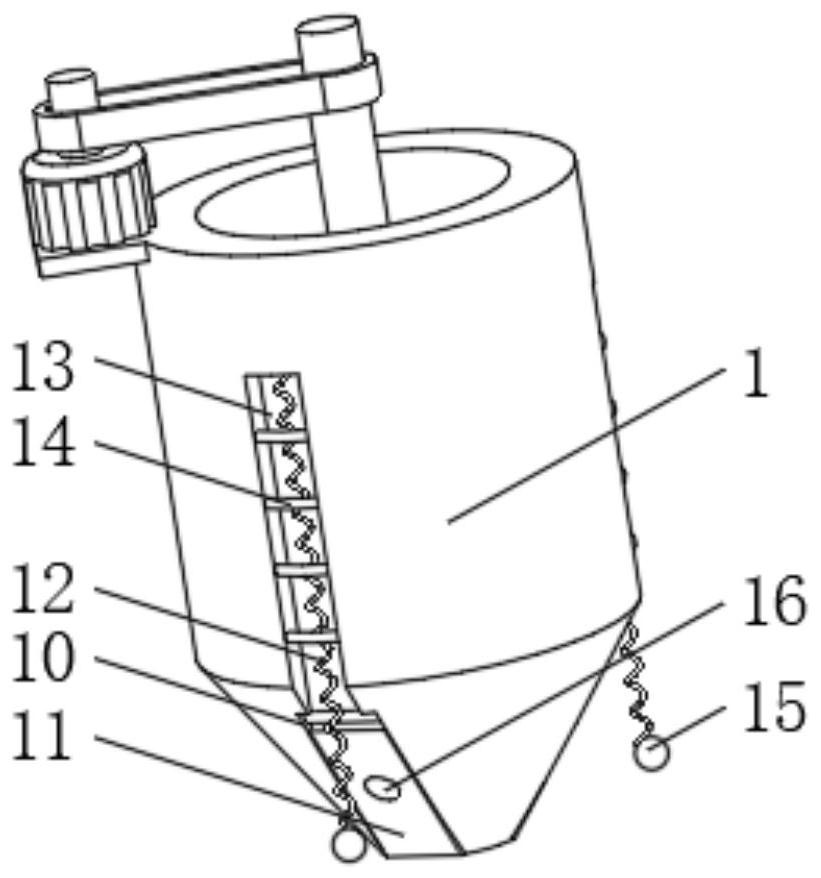

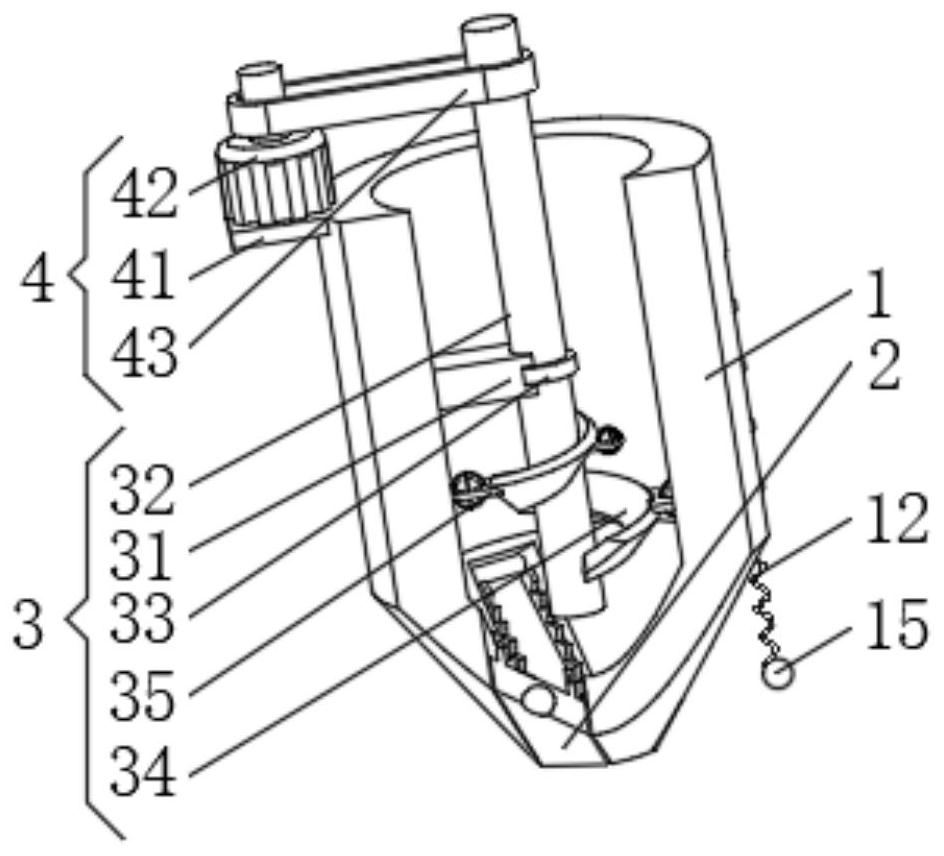

[0033] see Figure 1-5 , the present invention provides a technical solution: a rail transit sand spreading system, comprising a storage tank 1, the top of the storage tank 1 is designed as an opening, the bottom of the storage tank 1 is provided with a sand sprinkling port 2, and the storage tank 1 The internal settings are:

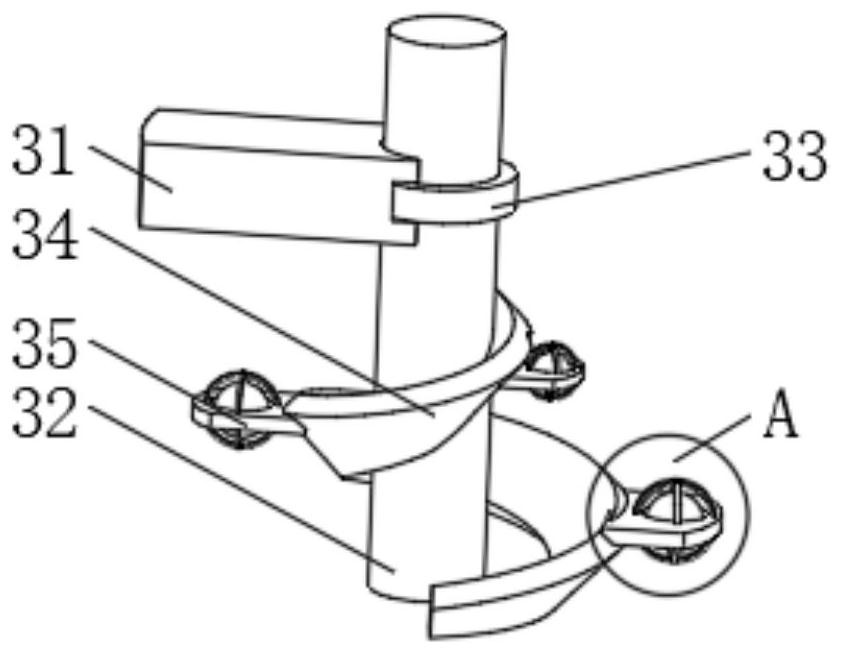

[0034] Sand crushing device 3, the sand crushing device 3 has a support rod 31, a sand crushing rod 32 is installed inside the storage tank 1, the top end of the sand crushing rod 32 extends to the outside of the material storage tank 1, and the outside of the sand crushing rod 32 The limit protruding ring 33 is installed, and the limit protruding ring 33 extends to the inside of the support bar 31 and is slidably connected with the support bar 31. The bottom end of the broken sand bar 32 is fixedly connected with a spiral plate 34, and the spiral plate 34 is away from the bottom of the broken sand bar 32. One side is fixedly connected with broken sand...

Embodiment 2

[0042] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, an expansion slot 10 is evenly opened at the bottom of the storage tank 1, the expansion slot 10 runs through the storage tank 1, and the inner top of the expansion slot 10 is rotatably connected with an expansion board 11. One side of the expansion board 11 is symmetrically installed with sawtooth boards.

[0043] A return spring 12 is installed on one side of the expansion plate 11 , and the end of the return spring 12 away from the expansion plate 11 is fixedly connected with the storage barrel 1 .

[0044] The outer side of the storage tank 1 is provided with a storage tank 13, and the limit round rod 14 is fixedly connected between the two sides of the inner wall of the storage tank 13. The inner wall is fixedly connected, and the return spring 12 is slidably connected with the limit round rod 14.

[0045] One end of the return spring 12 away from the storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com