Optimized structure for reducing rotation resistance of roller of rubber recovery conveying equipment

A technology of roller rotation and transmission equipment, which is applied in the direction of conveyor objects, cleaning devices, transportation and packaging, etc. It can solve the problems of increasing the rotation resistance of the roller, the increase of the rotation resistance of the roller, and the pollution of the roller surface, so as to reduce the frictional resistance, Effects of reducing waste and reducing rotational resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

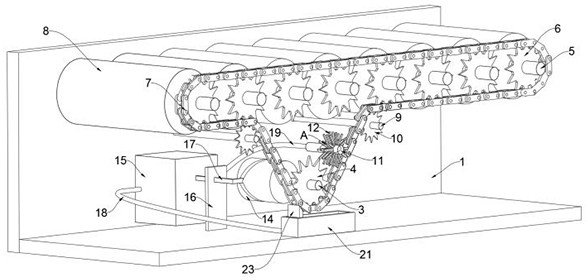

[0039] Refer Figure 7 - Figure 8 In this embodiment, the present embodiment is different from the embodiment: the inner wall of the base 1 is rotated and the tension wheel 28 is connected, and the inner wall of the base 1 is rotated and connected to the drive rod 24, and the drive rod 24 is fixedly connected to the driven wheel 25, one of the round rod 9. The side walls are fixedly connected to the active wheel 26, the tension wheel 28, the active wheel 26, and the driven wheel 25 constitute the V-shaped structure, the tension wheel 28, the active wheel 26, and the driven wheel 25 are connected by the synchronous belt 27, and the synchronous belt 27 is provided on the synchronous belt 27 The cleaning mechanism for brushing the debris on the drum 8 is fixed, and the roller 9 connected to the active wheel 26 is selected to be away from the driven wheel 25, so that the soft brush felt on the synchronous belt 27 can be more Multi-roller 8 cleans up.

[0040] The cleaning structure inc...

Embodiment 3

[0043] Refer Figure 9 In this example, the second embodiment is that the inner wall of each roller 8 is provided with a plurality of heating wire 30, a hot wire 30, and an external battery electrical connection. The inner wall of the cleaning cartridge 29 is fixedly connected to a soft base 31. The soft base 31 is fixedly connected to a plurality of wash block 32, and the brush block 32 is always opposed to the soft brush felt to be slidably reversed, thereby scraping the adhesive impurities adhered to the soft bristles.

[0044] In this embodiment, the heating wire 30 is powered, thereby generating a certain temperature in the inner wall of each drum 8, so that even when the surface of the drum 8 adhesive impurities, the temperature rise is more advantageous for the soft brush felt pair. The removal of the viscous impurities avoids adhesion to the rubber, thereby affecting the recovery transfer of the rubber, and when it causes rubber to adhere to the drum 8, the rotation resista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com