Assembly type partition wall with self-locking function and mounting method thereof

A prefabricated and self-locking technology, applied in the field of building decoration, can solve the problems of on-site construction environmental pollution, increase on-site materials, waste man-hours, etc., and achieve the effect of ensuring sound insulation, convenient installation, and ensuring connection firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

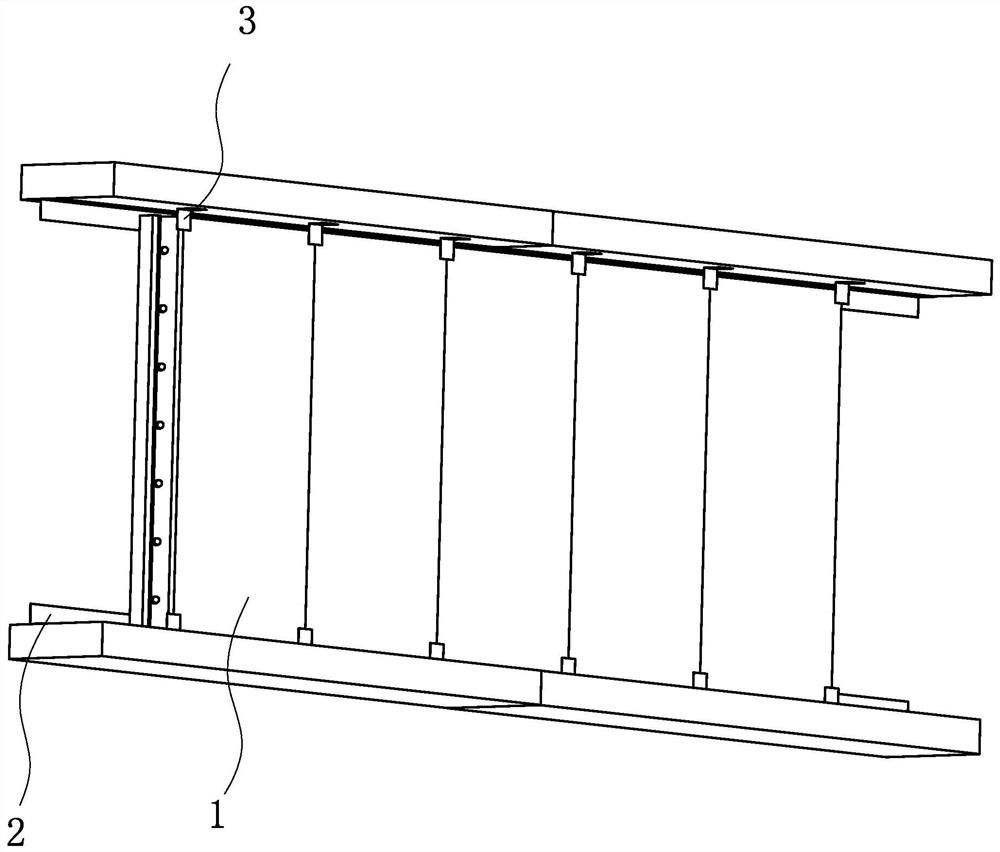

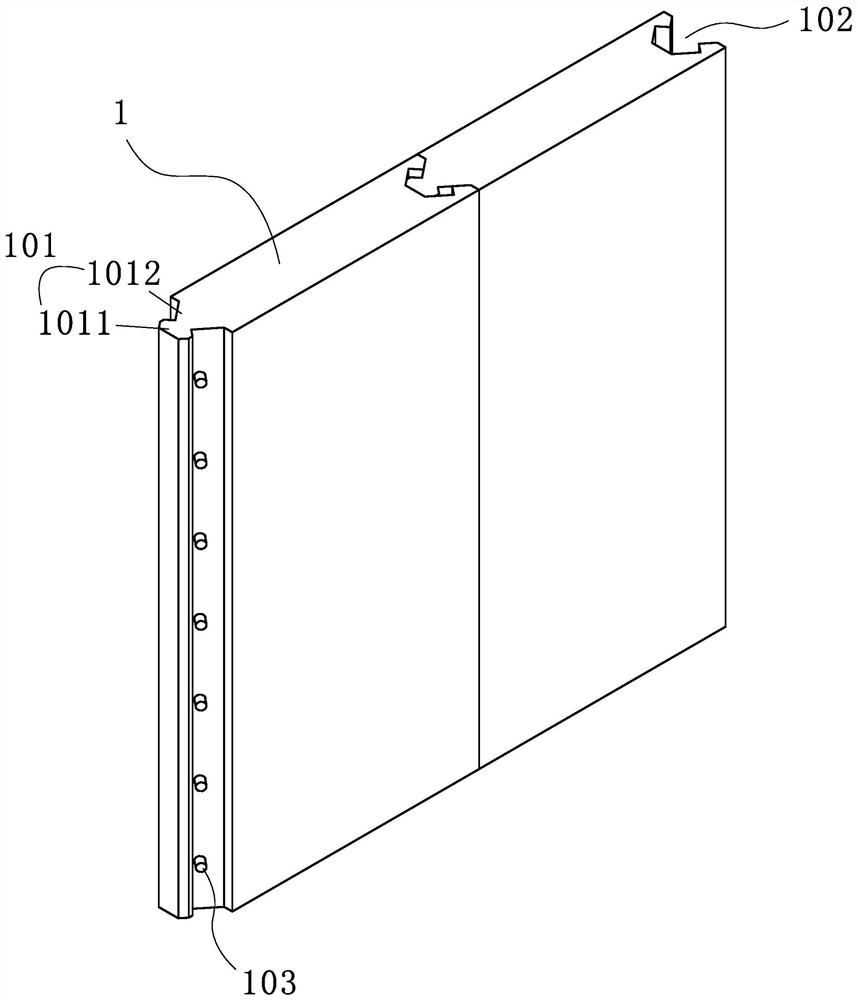

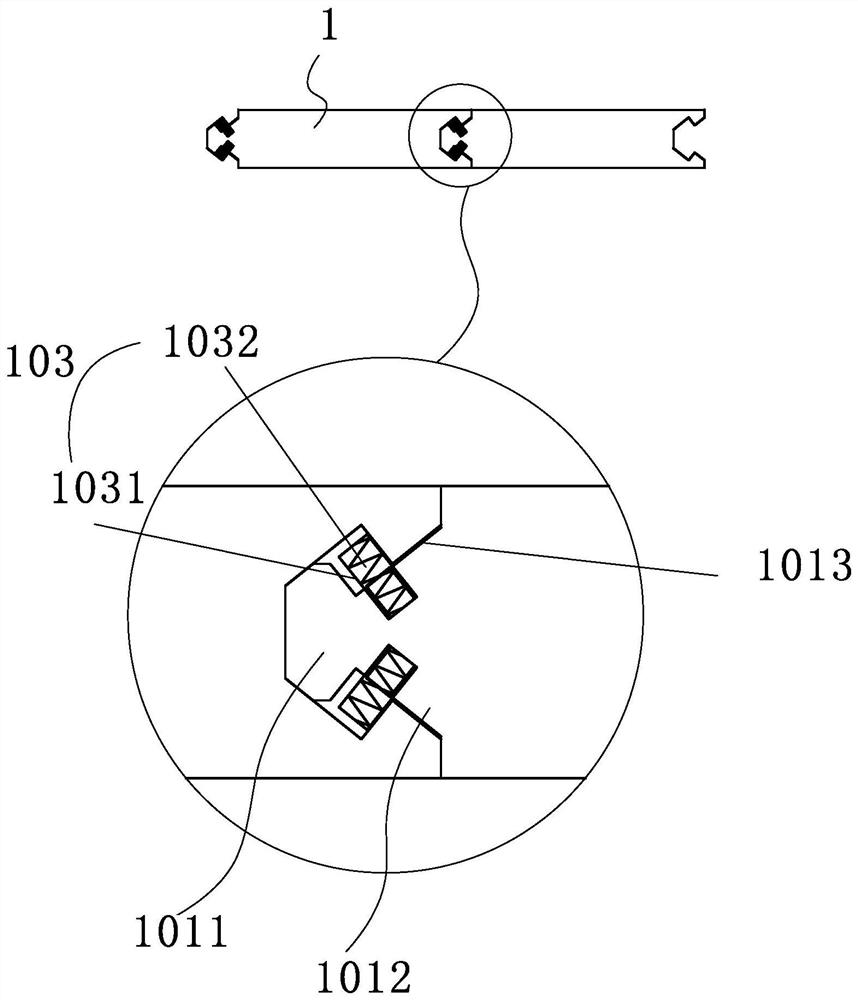

[0040] Such as figure 1 , figure 2 , image 3 In the shown embodiment 1, a prefabricated partition wall with a self-locking function includes roof and ground keels 4, strip partition walls and installation keels for installing the strip partition walls on the top and ground joists 4 2. The slat partition wall includes a slat body 1. A rebate 101 is provided on one side of the slat body 1, and a socket 102 matching with the rebate 101 is provided on the other side. The rebate 101 of the slat partition wall to be installed Inserted at the socket 102 of the adjacent installed strip partition wall, a self-locking structure 103 is provided on the tongue and groove 101, and the self-locking structure 103 includes a side wall of the tongue and groove 101 of the strip partition wall The embedded hole and the elastic member arranged in the embedded hole, the elastic member includes a steel pipe 1031 and a spring 1032, the steel pipe 1031 is partially inserted into the embedded hole,...

Embodiment 2

[0048] A prefabricated partition wall with self-locking function, comprising the following steps:

[0049] Step 1: If Figure 4 As shown, the top and ground keels 4 are installed, and the keels 2 are fixedly installed on the top and ground keels 4 respectively;

[0050] Step 2: If Figure 5 As shown, install a slatted partition wall and insert the slatted partition wall vertically into the installation keel 2;

[0051] Step 3: If Image 6 As shown, to install other slat partition walls, insert the groove 101 of the slat partition wall to be installed into the socket 102 of the installed partition wall slats to realize self-locking between the slat partition walls, and place the remaining Batten partitions are installed in the same way;

[0052] Step 4: If Figure 7 As shown, the L-shaped keel is used for finishing to complete the installation.

[0053] In step 1, the keel installed first can play the role of positioning and temporary fixation. In step 2, the keel 2 insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com