A guide rail slider type adjustable speed magnetic coupler

A technology of magnetic coupling and linear guide rail slider, which is applied in the direction of permanent magnet clutch/brake, electric brake/clutch, electromechanical device, etc., can solve the problems of uneven air gap thickness, affecting transmission efficiency, large interval, etc., to achieve Compact structure, stable transmission, and the effect of reducing axial load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

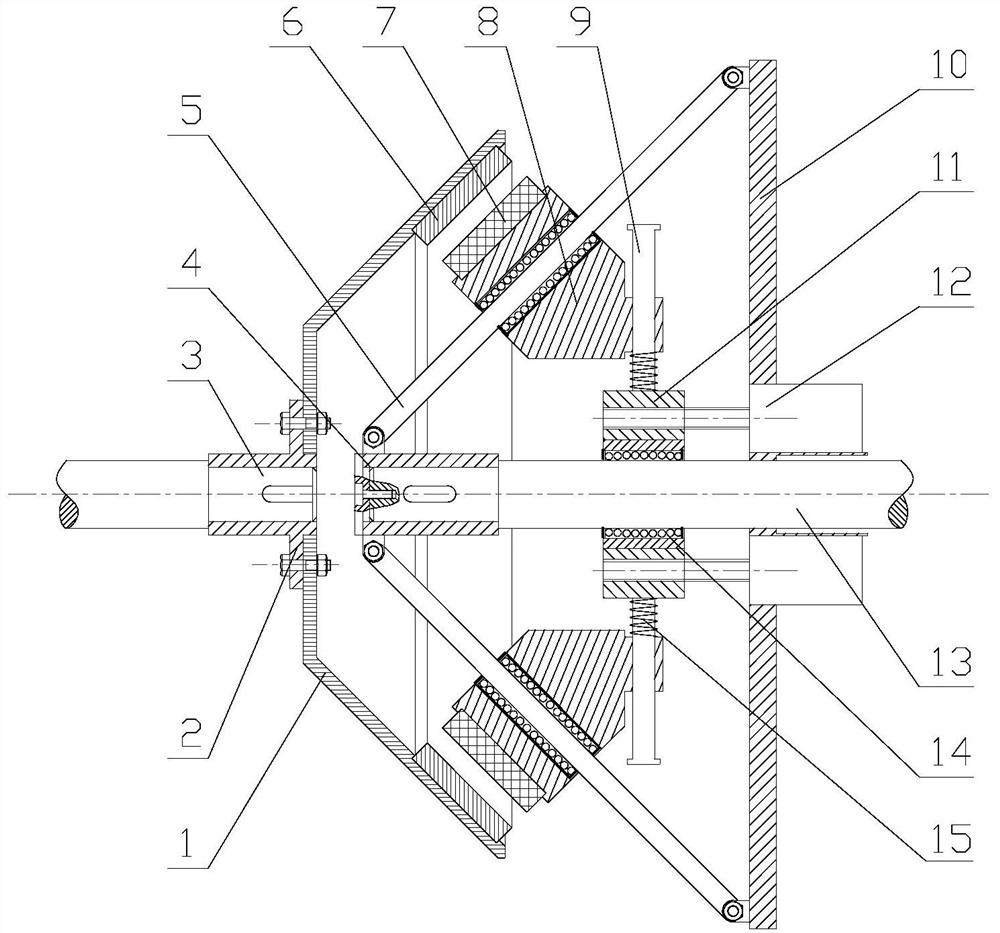

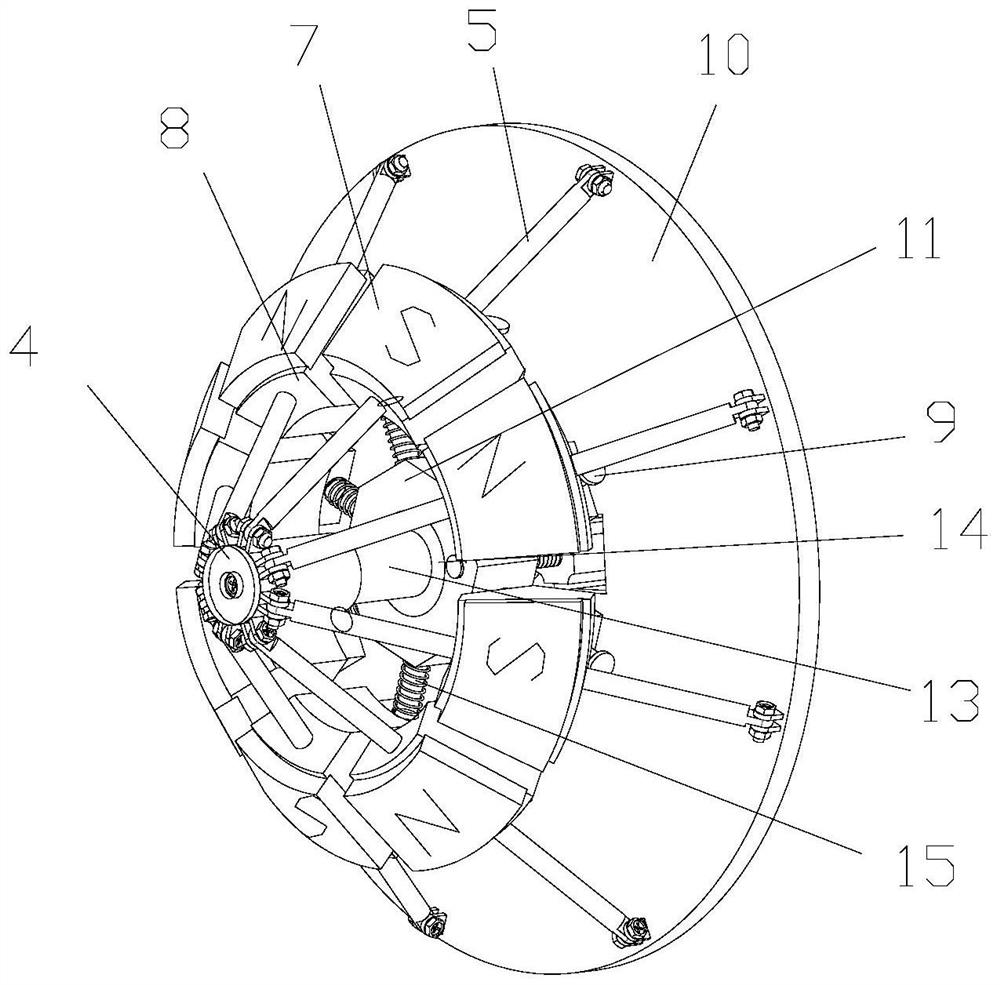

[0027] like figure 1 As shown, a guide rail slider type adjustable speed magnetic coupler includes a conductor frustum-shaped disk assembly and a permanent magnet conical disk assembly, wherein the speed regulating device is installed on the permanent magnet conical disk assembly, and the conductor frustum-shaped disk assembly The assembly includes a conductor ring 6, a driven base plate 1, a driven shaft 3 and a driven shaft sleeve 2, the right end of the driven shaft 3 is connected to the driven shaft sleeve 2 through a key, and the driven shaft sleeve 2 is connected to the driven shaft sleeve 2. The base discs 1 are fixed together by bolts, and the conductor ring 6 is installed on the inner surface of the driven base disc 1 to form a conductor frustum-shaped disc.

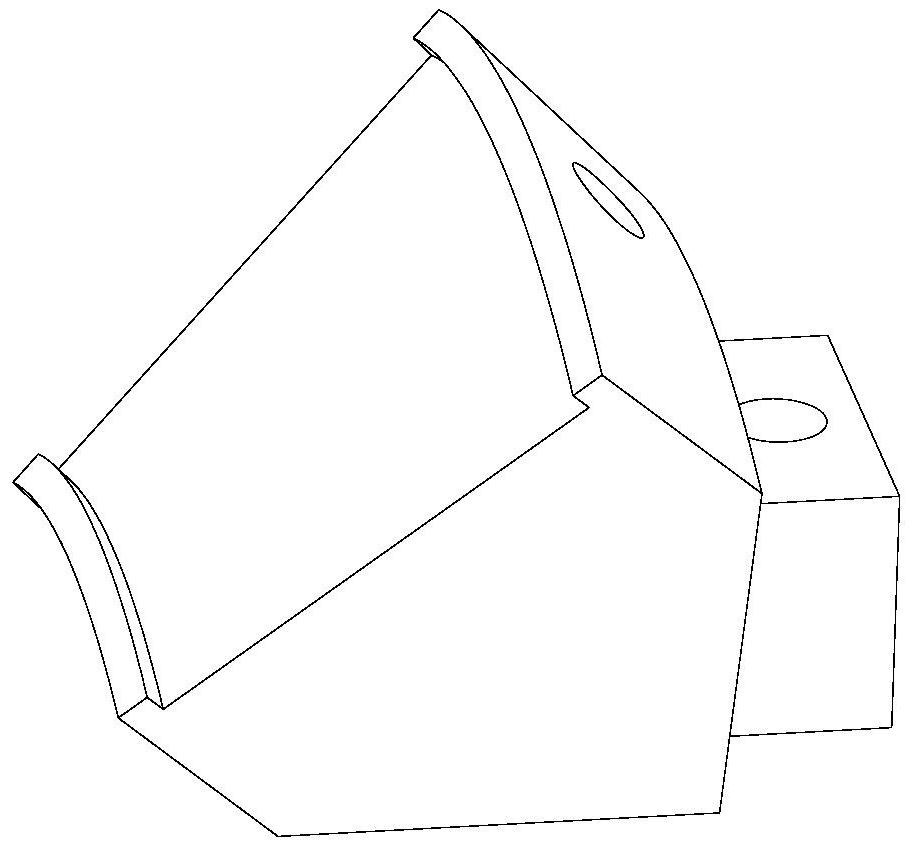

[0028] The permanent magnet tapered disk assembly includes a permanent magnet 7, a ball type linear guide rail slider 8, a guide rail 5, a fixed plate 10, a screw motor 12, a sleeve 11, a sliding rod 9, a compre...

Embodiment 2

[0032] The speed regulation principle of this embodiment is basically the same as that of Embodiment 1. The difference in structure is that the solid conductor ring of the conductor ring 6 in the conductor frustum-shaped disk assembly is replaced by a cage-type conductor ring, and the cage-type conductor ring is composed of conductor copper disks 17 and The yoke iron plate 16 is composed of, such as Image 6 shown. The surface of conductor copper plate 17 is processed with a number of rectangular grooves, and the surface of yoke iron plate 16 is processed with small bumps with the same shape as the rectangular grooves. The fan-shaped grooves and small bumps are interference fit, and after the fit, a cage-shaped conductor ring is formed and embedded in the driven substrate. The conductor ring is fixed on the driven base plate 1 by means of screw connection, riveting or welding. The difference in the working principle is that the motor drives the permanent magnet conical disk a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com