Battery row, battery pack and manufacturing methods of battery row and battery pack

A manufacturing method and battery row technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of small laser energy concentration points, damage, and failure to meet reliable electrical connections, and achieve good contact resistance consistency and high The effect of electrical connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] This Example 1 provides a composite electrical connector battery discharge process, for a cylindrical battery prepared as a single row within the rows in parallel and in series between the CTP module, particularly suitable for the preparation of new energy vehicle power battery cell, and the same applies to the low-speed electric vehicles, electric bicycles and other storage products.

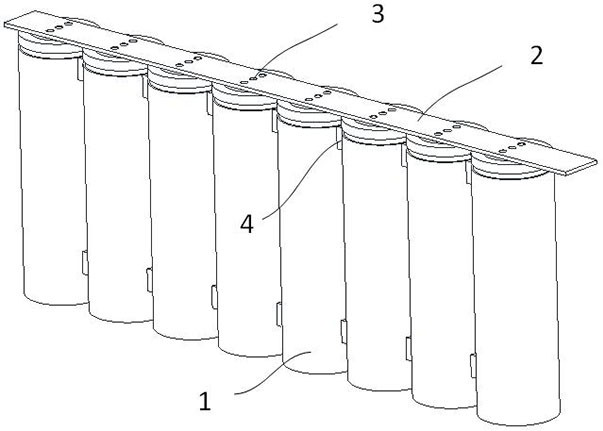

[0075] according to Figure 1 - Figure 3 A battery discharge embodiment of the present embodiment, i.e., a composite electrically connected to the battery discharge process, the battery is one row of the base unit power battery module, comprising:

[0076] A plurality of single cylindrical battery 1, a plurality of cylindrical cells 1 are arranged in single rows; single cylindrical cell 1 includes a top pole and the pole housing side; top pole is made of a conductive metal material; battery discharge All single cylindrical cells 1 are arranged in the same direction;

[0077] 2 busbar made of ...

Embodiment 2

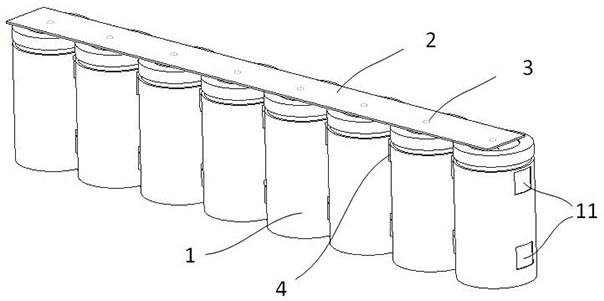

[0089] This Example 2 provides a composite electrically connected to the battery discharge process, the structure mainly different from Embodiment 2 in the busbar 1. according to Figure 4 - Figure 5 , Disposed on the bus bar 2 comprises a bent end portion 21 of the bus, the bus bent portion 21 positioned outside both ends of the battery discharge. Bending both end portions of the bus 21 may have, it may be present only at one end 2 of the bus bar.

[0090] The bent portion 21 of the bus functions include but are not limited to assume the function of electrically connecting the battery to the other row corresponds to the external top side opposite pole. The bent portion of the bus 21 further includes functions to constrain the longitudinal gap discharge the battery to a certain extent.

[0091] Preferably, the Figure 5 , With a distance between the single cylindrical battery 21 from the bent portion of the bus end portion of the side surface of the pole housing 1; monomer Preferabl...

Embodiment 3

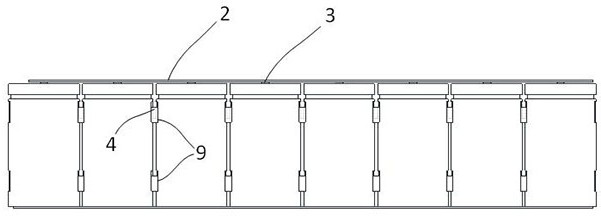

[0093] according to Figure 6 - Figure 9 The present example provides a composite 3 is electrically connected to the battery technology, the above-described embodiments comprises a plurality of arrays arranged in a battery disclosed in any row, parallel rows inside the battery of the battery pack, the serial connection between adjacent cells in a row.

[0094] Battery pole row side of the housing at least partially outside of the housing as a pole of a battery discharge.

[0095] As a preferred embodiment, the housing further comprising a plurality of pole 7 bridge approach, Approach in each pole housing 7 are electrically connected to the side surface of housing a battery pole row.

[0096] Each row of the battery pole busbar outer housing sequentially with the neighboring rows of cells 2 are electrically connected in series between adjacent cells in a row; first busbar cell 2 as a top row of the external pole of the battery pack.

[0097] As a preferred embodiment, the adjacent r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com