Cutting method for upper and lower grooving of 2DV groove cover plate

A cutting method and technology of slot cover, which is applied in the field of optical communication, can solve the problems of not being able to accurately fix the horizontal positions of the upper and lower rows of optical fibers, etc., and achieve the effects of strong practicability, satisfactory vertical positioning, and significant progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

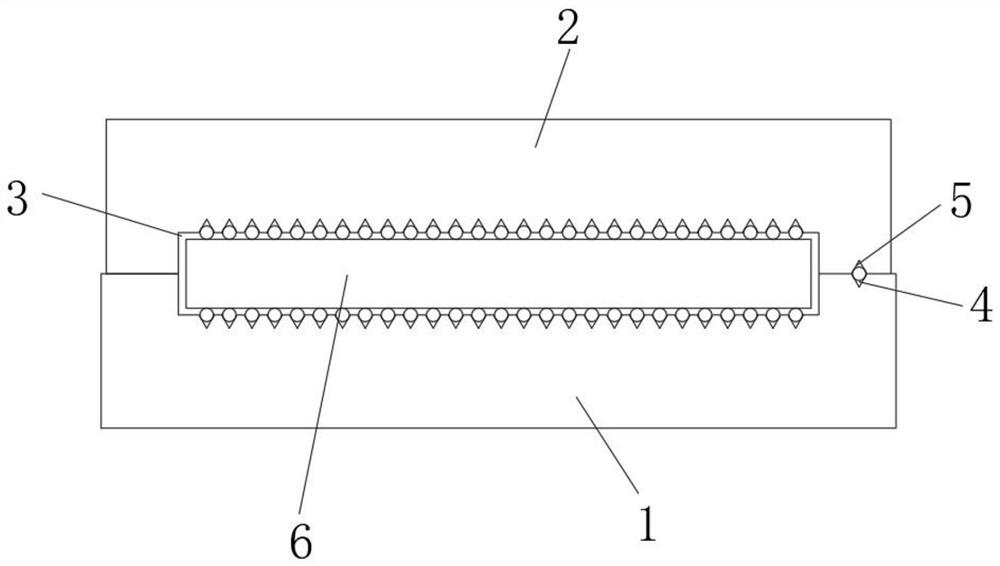

[0027] Embodiment 1 of the present invention, a cutting method for cutting grooves up and down on a 2DV groove cover plate, comprising the following steps:

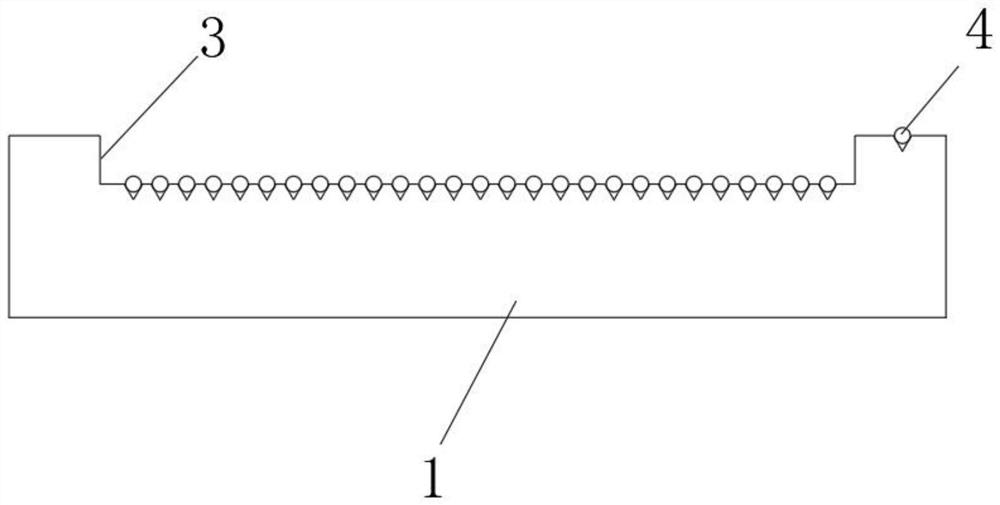

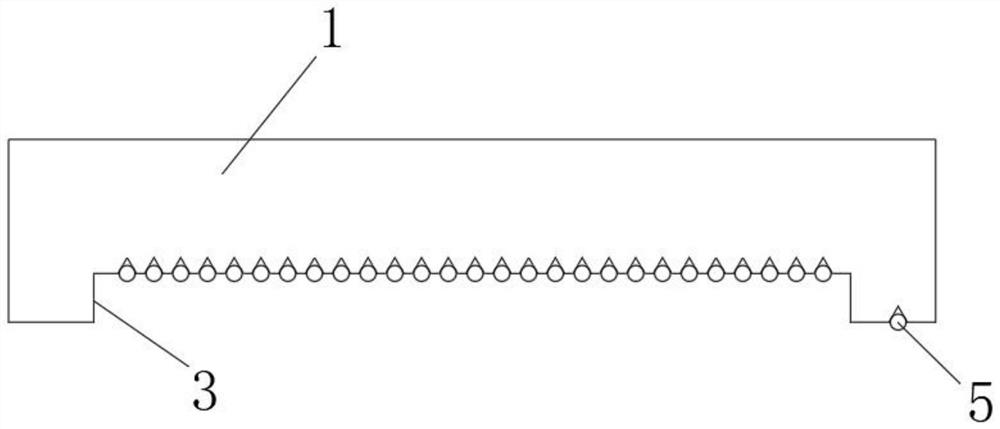

[0028] S1: Preparation, first prepare the glass plate 1 and the cover plate 2, then open the groove 3 on the glass plate 1 and the cover plate 2, and ensure that the size of the groove 3 on the glass plate 1 and the cover plate 2 is the same;

[0029] S2: Open positioning holes, firstly open positioning hole A4 on the top surface of glass plate 1, then open positioning hole B5 on the bottom surface of cover plate 2, and ensure that the positions of positioning hole A4 and positioning hole B5 are the same;

[0030] S3: Set up fiber grooves, and then set several groups of fiber grooves in the groove 3, the fiber grooves are mainly used for placing optical fibers;

[0031] S4: Vertical positioning, and then a glass block 6 is installed in the groove 3 between the glass plate 1 and the cover plate 2 as a fixation, so as to li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com