Adhesive sheet

A technology of adhesive sheets and adhesive surfaces, which is applied in the direction of adhesives, film/sheet adhesives, adhesive heating bonding methods, etc., which can solve the problems of reduced practicability, restrictions on adhesive thickness, and substrates. Or the problem of poor adhesion of the processing table, to achieve the effect of suppressing the generation of cutting chips and excellent cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0100] Hereinafter, although an Example demonstrates this invention concretely, this invention is not limited to these Examples. Evaluation methods in Examples are as follows. In addition, in an Example, unless otherwise indicated, "part" and "%" are based on weight.

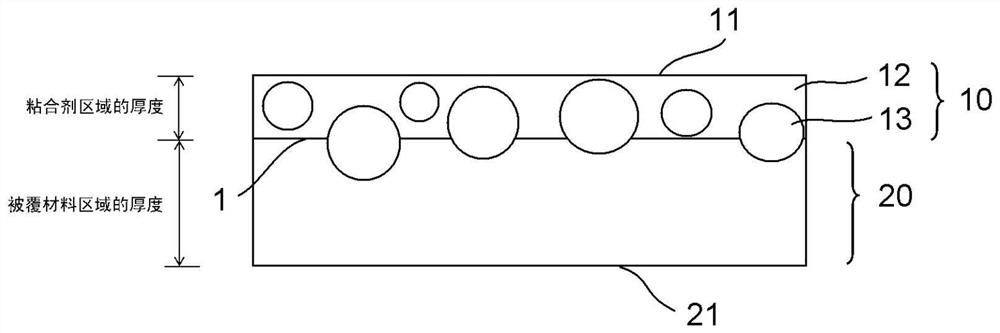

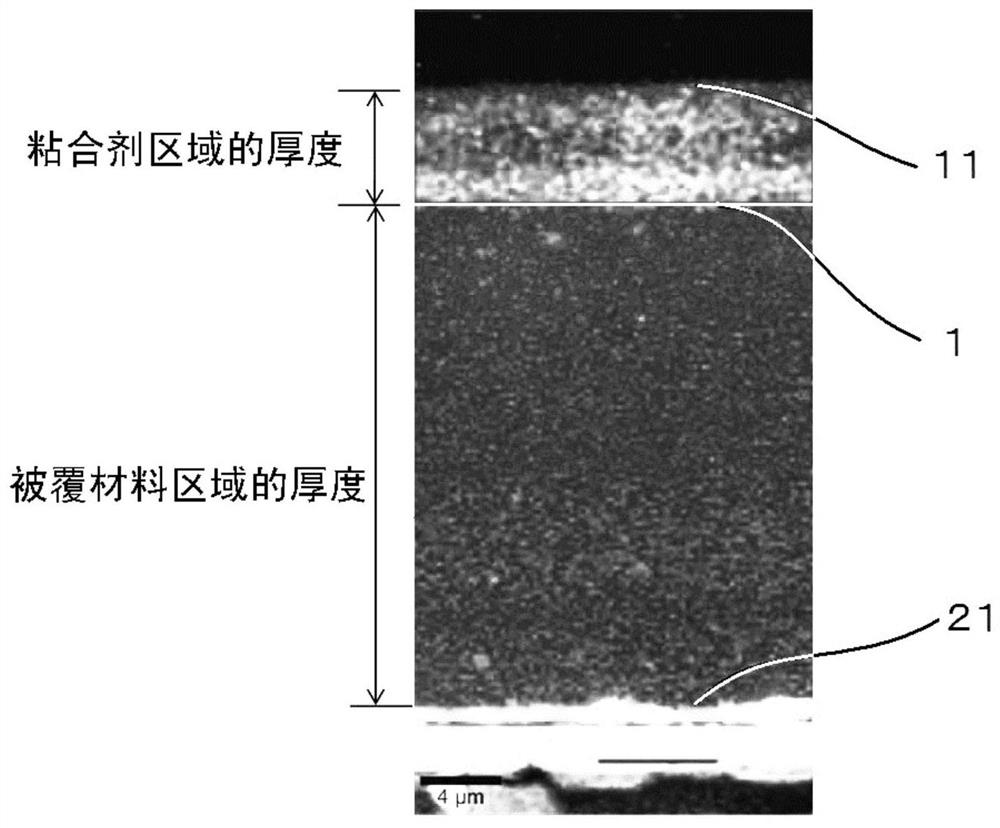

[0101] (1) Determination of the thickness of the adhesive region and the coating material region in Raman microscopic imaging

[0102] The PSA sheets obtained in Examples 1 to 3, 5, 6, and 12 to 15 were sliced with a microtome to prepare measurement samples. The cross-section of the measurement sample was subjected to spectral analysis based on Raman spectroscopy using alpha300RSA manufactured by WITec Corporation, based on peaks derived from components added only to the coating material region (for example, active energy ray reactive oligomerization in Example 3). 1640cm of object (UV1700B) -1 The peak intensity of the peak) measures the thickness of the covering material area and the adhesive area. Takin...

manufacture example 1

[0147] [Production Example 1] Preparation of Polymer 1

[0148] After adding 100 parts of butyl acrylate, 5 parts of acrylic acid, and 0.2 part of benzoyl peroxide as a polymerization initiator to toluene, it heated and obtained the toluene solution of an acrylic copolymer (polymer 1).

manufacture example 2

[0149] [Production Example 2] Preparation of Polymer 2

[0150] Add 30 parts of 2-ethylhexyl acrylate, 70 parts of ethyl acrylate, 4 parts of 2-hydroxyethyl acrylate, 5 parts of N-phenylmaleimide, and benzene peroxide as a polymerization initiator in toluene After 0.2 parts of formyl, it heated and obtained the toluene solution of an acrylic copolymer (polymer 2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com