Continuously variable transmission and vehicle

A continuously variable transmission and speed ratio technology, applied in the field of vehicles, can solve the problems affecting starting power, low transmission efficiency, pulley slipping, etc., and achieve the effect of avoiding pulley slipping, ensuring starting power and sufficient performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

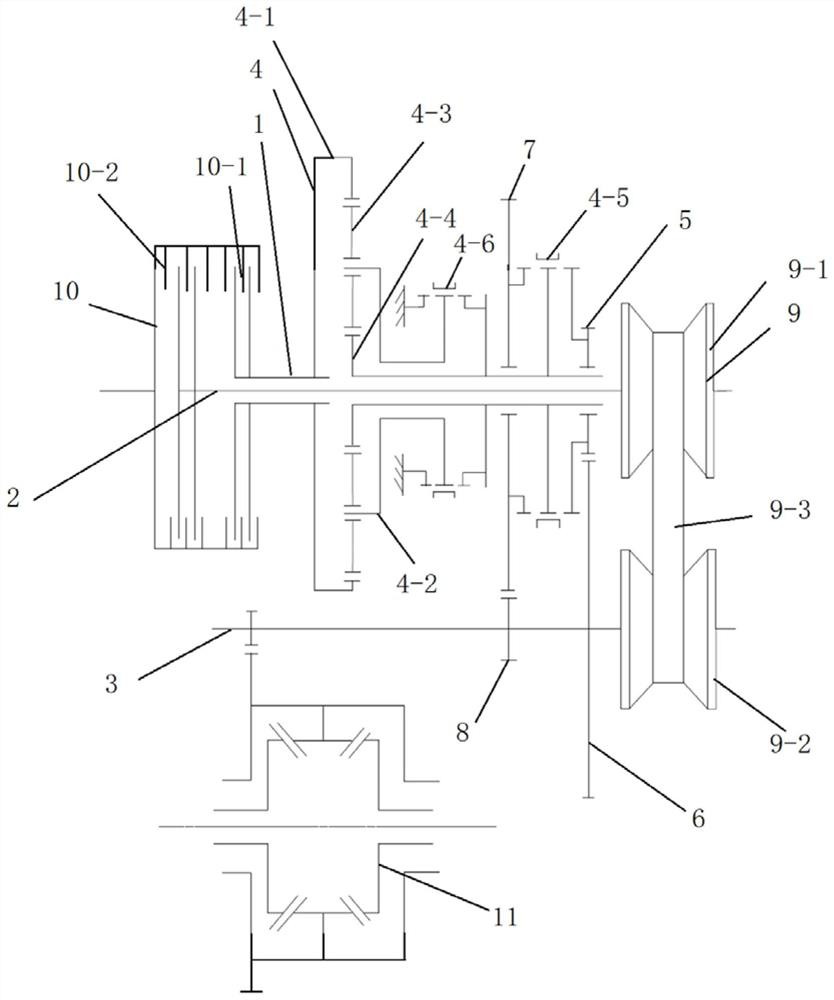

[0019] see figure 1 A continuously variable transmission provided by an embodiment of the present invention includes: a housing, a first input shaft 1, a second input shaft 2, an output shaft 3, a planetary mechanism 4, a starting gear driving gear 5, a starting gear driven gear 6, High gear driving gear 7, high gear driven gear 8 and CVT transmission system 9.

[0020] First input shaft 1, second input shaft 2, output shaft 3, planetary mechanism 4, starting gear driving gear 5, starting gear driven gear 6, high speed driving gear 7, high speed driven gear 8 and CVT transmission system 9 are all set in the housing.

[0021] The input end of the planetary mechanism 4 is connected with the first input shaft 1 .

[0022] The output end of the planetary mechanism 4 can be selectively connected with the starting gear driving gear 5 or the high gear driving gear 7 .

[0023] The starting gear driven gear 6 and the high speed gear driven gear 8 are all arranged on the output shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com