Method for acquiring vibration noise contour domain diagram of electric driving system

An electric drive system, vibration and noise technology, applied in the direction of measuring vibration, vibration measurement in solids, testing of mechanical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The concrete process of this embodiment is as follows:

[0050] (1) Obtain the torque and speed change curve of the external characteristics of the electric drive system during the acceleration process

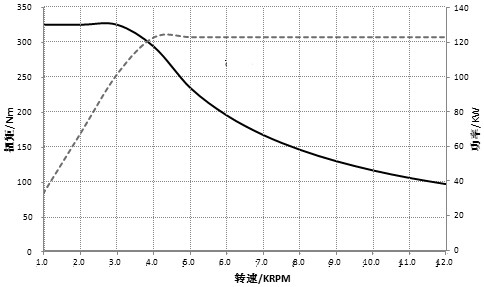

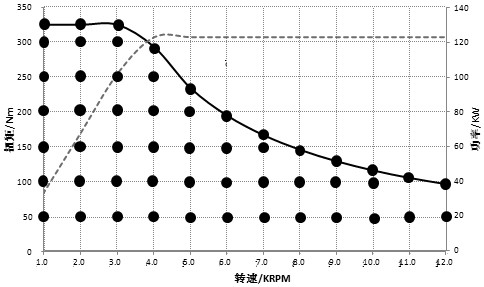

[0051] ① Combined with the motor performance parameters, obtain the motor external characteristic curve (torque / time, speed / time) according to the following formula and bench test, such as figure 1 as shown, figure 1 The solid line represents torque, and the dashed line represents power.

[0052] T=K*P / R

[0053] Among them, K is a constant of 9550, T is the motor torque (Nm), P is the motor power (KW), and R is the motor speed (r / min).

[0054] ② According to the area included in the torque curve, select the appropriate torque and speed point within its range. Taking the electric drive system of a vehicle as an example, the peak torque of the motor is 320Nm, the peak power is 120KW, and the maximum speed is 12000RPM. The selected speed and torque points to be teste...

Embodiment 2

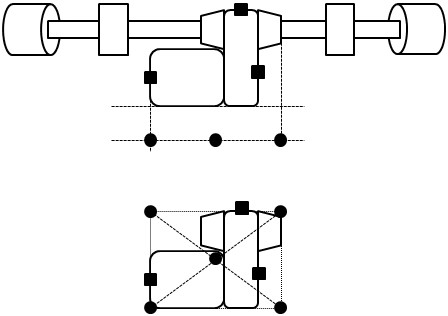

[0082] Taking an electric light bus model as an example, its electric drive system consists of a motor, a transmission, and a controller. The main noise sources are transmission gear meshing noise and electromagnetic noise. In the early stage of the development of this model, engineers conducted vibration and noise testing and analysis on the electric drive system of this model, obtained high-level maps of vibration and noise, and judged which points are forbidden areas for vibration and noise, and compared them with the vibration and noise under the vehicle's working conditions. Compare and evaluate its accuracy.

[0083] Predict the abnormal vibration and noise of the electric drive system in advance:

[0084] Judging from the contour diagram of the 8.63-order gear meshing vibration of the electric drive system, the magnitude of vibration is large at 2500-3500RPM on the abscissa and 25-70Nm on the ordinate, such as Figure 8 As shown, it can be judged that there is abnormal...

Embodiment 3

[0089] Guide the MCU calibration to avoid high-noise areas reasonably:

[0090] From the contour map of the 48th-order electromagnetic noise of the electric drive system, in Figure 9 The noise in the area of 7000-10000rpm on the abscissa and 150-200Nm on the ordinate will be more serious, which may cause complaints from customers. When requiring the MCU to calibrate, try to avoid this area under the premise of meeting other performance requirements to avoid complaints.

[0091] The electric drive system was loaded into the vehicle for testing and driving evaluation. Under the full switch acceleration condition, there is high-frequency harsh noise in the range of 80-110Km / h. Judging from the vehicle test data, the noise belongs to the 48th-order electromagnetic noise of the motor.

[0092] Under other attribute requirements, adjust the full-switch acceleration torque curve through MCU calibration to keep it away from the area of 7000-10000rpm on the abscissa and 100-200Nm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com