Tobacco leaf quality grade classification prediction method based on principal component analysis and super learning

A principal component analysis and classification prediction technology, applied in prediction, character and pattern recognition, resources, etc., can solve the problems of low accuracy of tobacco leaf quality grade classification prediction and large differences in evaluation results, so as to avoid over-fitting problems. , the effect of improving accuracy and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical solutions, creative features, objectives and effects of the present invention easy to understand, the implementation modes of the present invention will be described in detail below.

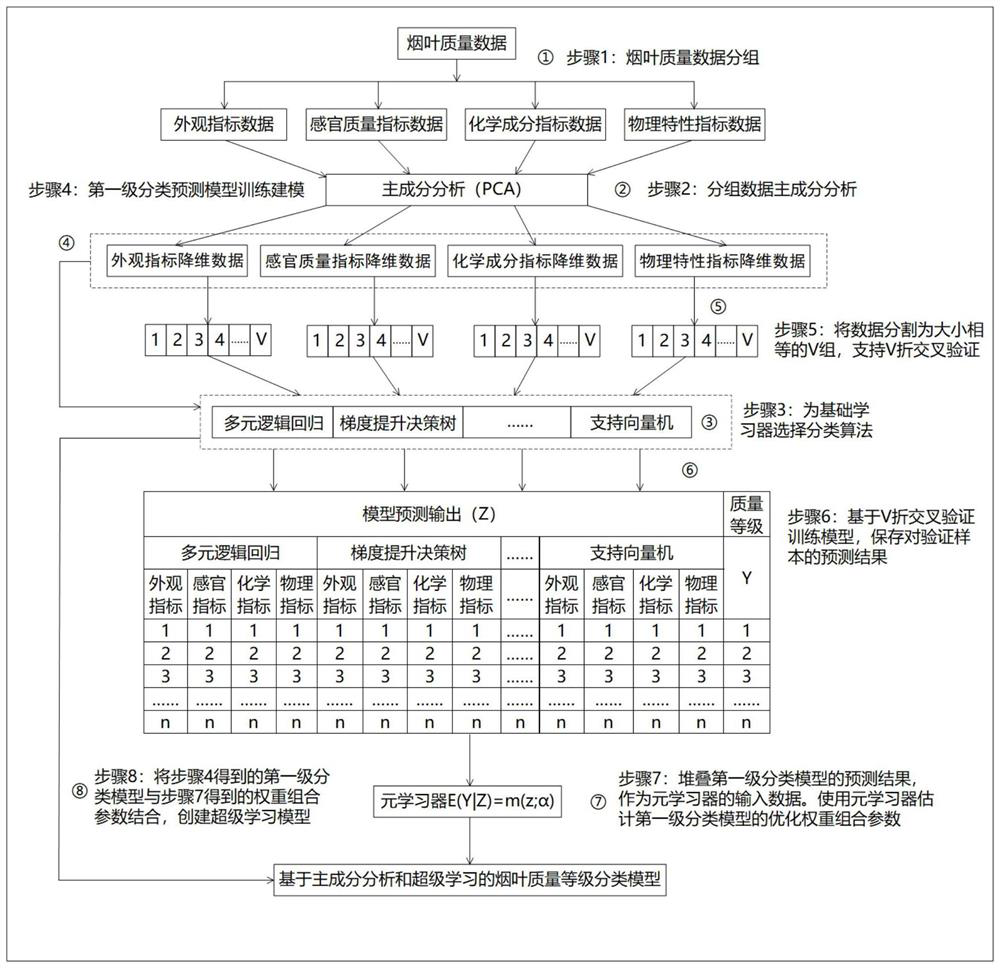

[0023] Aiming at the problems that the evaluation of tobacco leaf quality grades involves many indicators, the existing classification and evaluation methods have large differences in evaluation results, and the accuracy of classification and prediction of tobacco leaf quality grades is not high, the present invention proposes a tobacco leaf quality grade based on principal component analysis and super learning. The classification prediction method, the specific steps are as follows:

[0024] Step 1: Group the tobacco leaf quality data according to appearance index, sensory quality index, chemical composition index and physical property index respectively.

[0025] Tobacco leaf quality data includes appearance index, sensory quality index, chemical compositi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com