Valve-controlled shot circulating device of shot blasting machine

A valve control and circulation device technology, which is applied to the used abrasive processing device, abrasive feeding device, abrasive and other directions, can solve the problems of energy loss, poor permeability of fiber plastics, time difference, etc., to reduce the waste of pellets and the effect of artificial waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

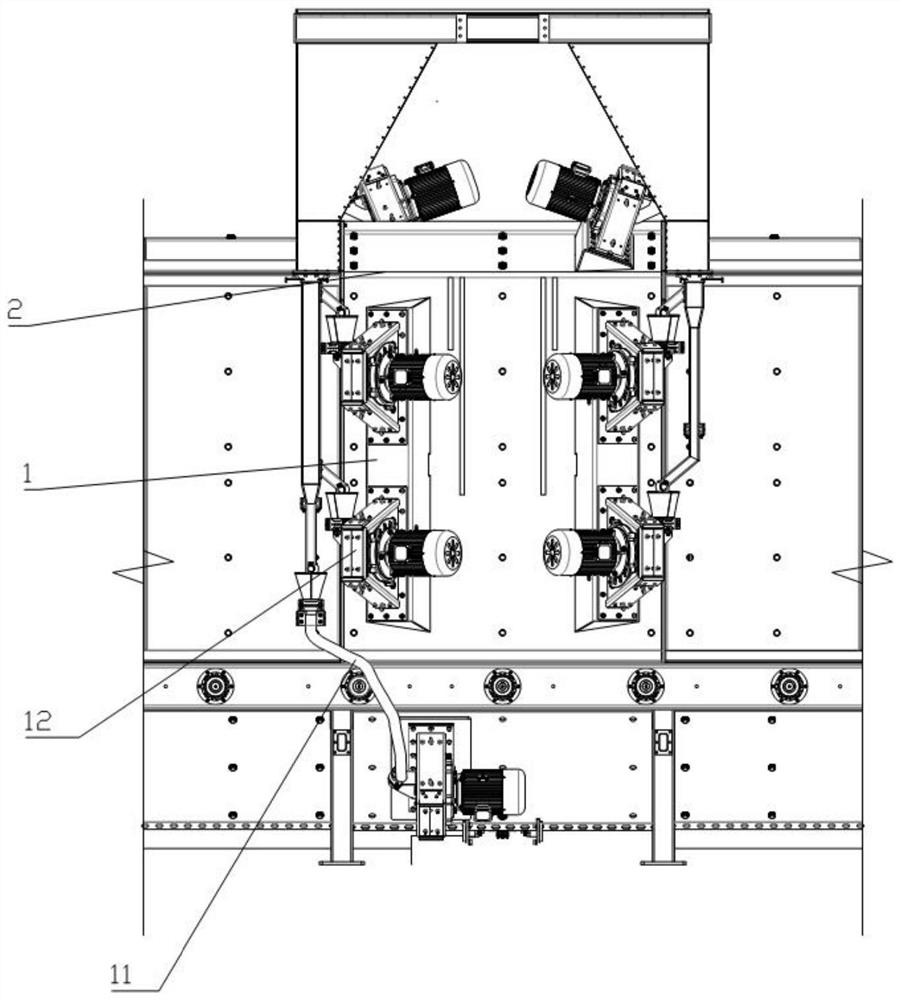

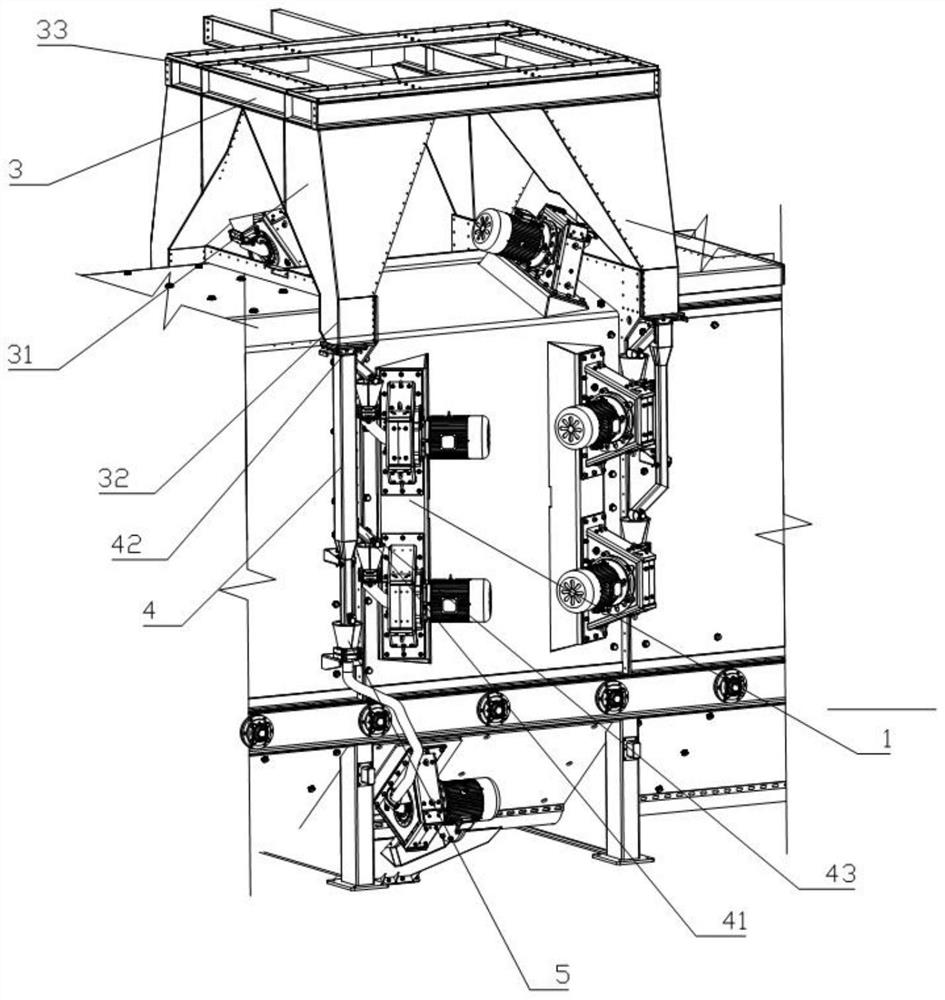

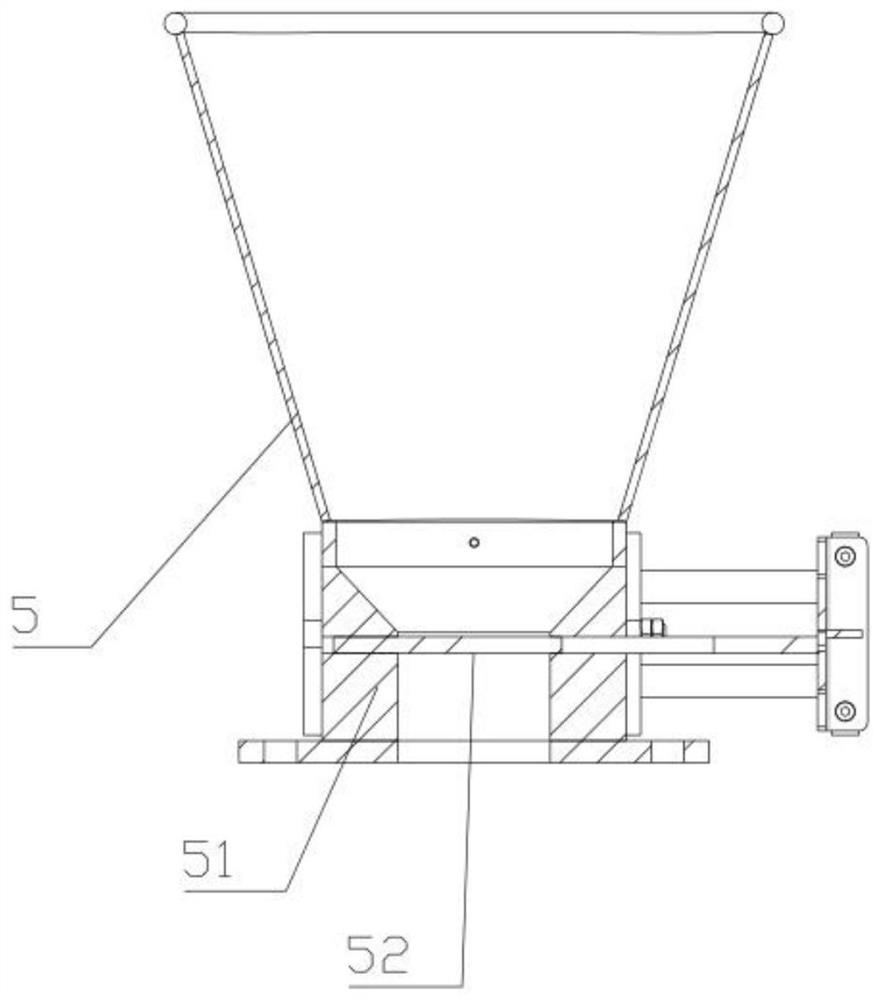

[0029] see Figure 1-5 , in Embodiment 1 of the present invention, the combined application of valves in the shot blasting machine shot material circulation system includes a mounting frame 2 and a shot blasting device 1 located in the mounting frame 2, and also includes a feed bin group 3 and shot blasting equipment. The silo group 3 is placed on the upper end of the installation frame 2 and is fixedly connected with the installation frame 2; the feed bin group 3 is provided with a plurality of silo bodies, and the bottom of each silo body is provided with feeding pipe fittings, and the feeding pipe fittings are placed in the feed bin group 3. The lower end of the silo group 3 surrounds the outside of the installation frame 2, and the feeding pipes communicate with each silo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com